Mineral processing method for comprehensively recovering weak magnetic iron, rare earth and fluorite

A mineral processing method and weak magnetic technology, applied in chemical instruments and methods, mechanical material recovery, recycling technology, etc., can solve problems such as waste of useful resources, environmental pollution, and ineffective use of fluorspar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

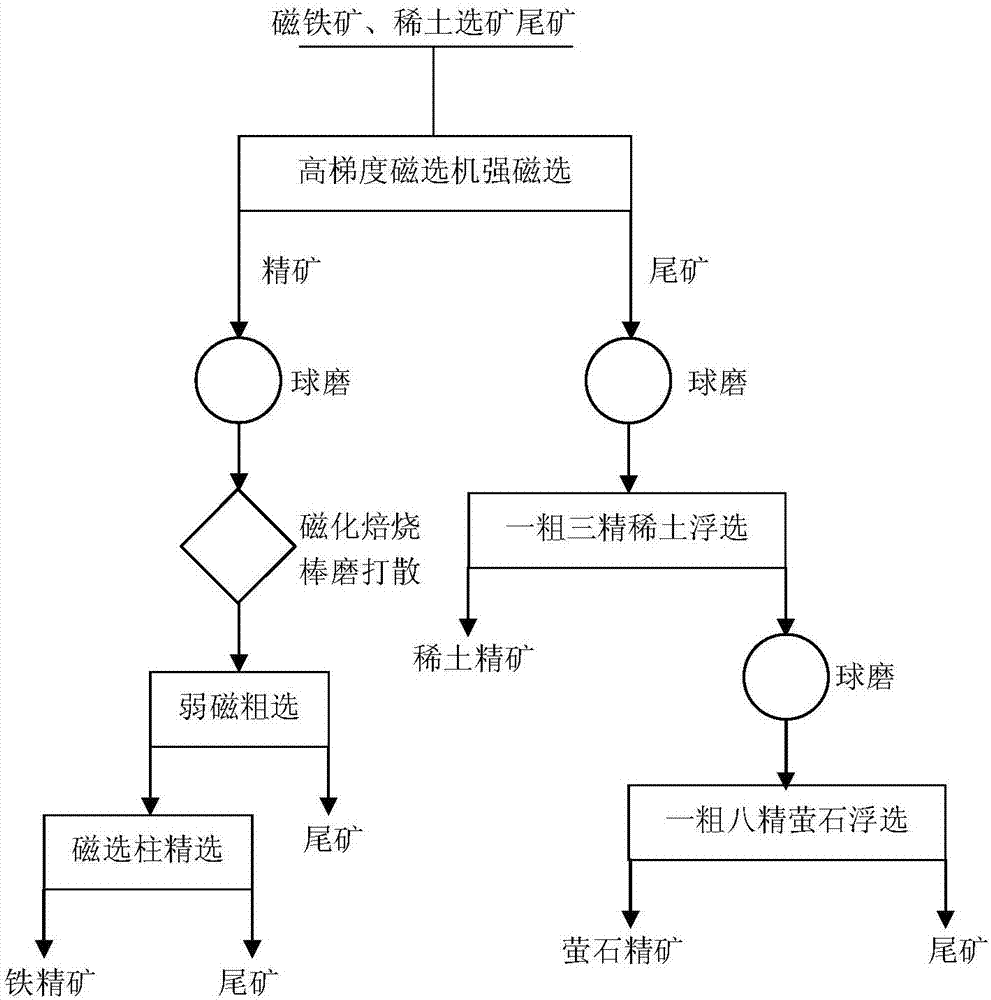

Image

Examples

Embodiment

[0014] A certain magnetite and rare earth beneficiation tailings in Baiyun Obo area, Inner Mongolia, the grade of TFe in the tailings is 21.6%, the grade of REO is 4.85% and the grade of CaF 2 Grade 22.5%. The tailings are subjected to strong magnetic separation with a high-gradient magnetic separator at a magnetic field strength of 0.7T, and the iron concentrate is ground to -45 μm by a ball mill, accounting for 82%, and after drying, it is mixed with activated carbon at a weight ratio of 0.18:1 , magnetized roasting at a roasting temperature of 720°C for 80 minutes, and the magnetized roasted product was ground with a rod mill for 2 minutes to dissociate and disperse. Under the condition of a 1250Gs magnetic field, a drum-type magnetic separator was used for weak magnetic separation to obtain TFe grade 56 % of the weak magnetic separation concentrate, the weak magnetic separation concentrate is selected by a magnetic separation column. The magnetic separation column selectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com