Hollow spherical strontium titanate powder and preparation method thereof

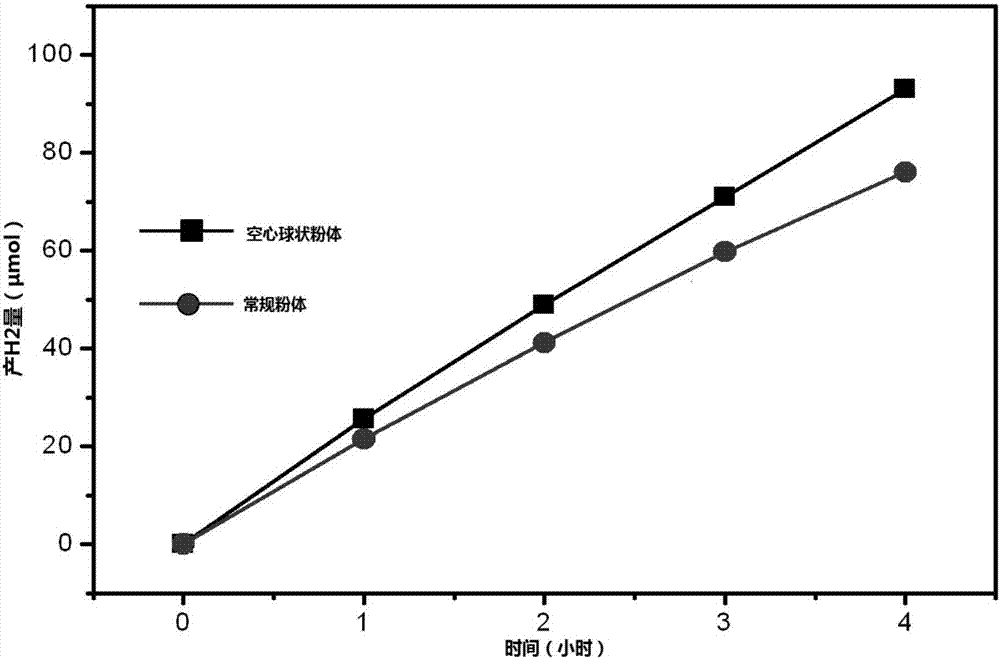

A hollow spherical, strontium titanate powder technology, used in titanate, alkaline earth metal titanate, chemical instruments and methods, etc., can solve the problem of uneven powder quality and size, difficult to control particle morphology, high energy consumption, etc. problems, to achieve the effects of easy semiconducting, easy doping modification, and high photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

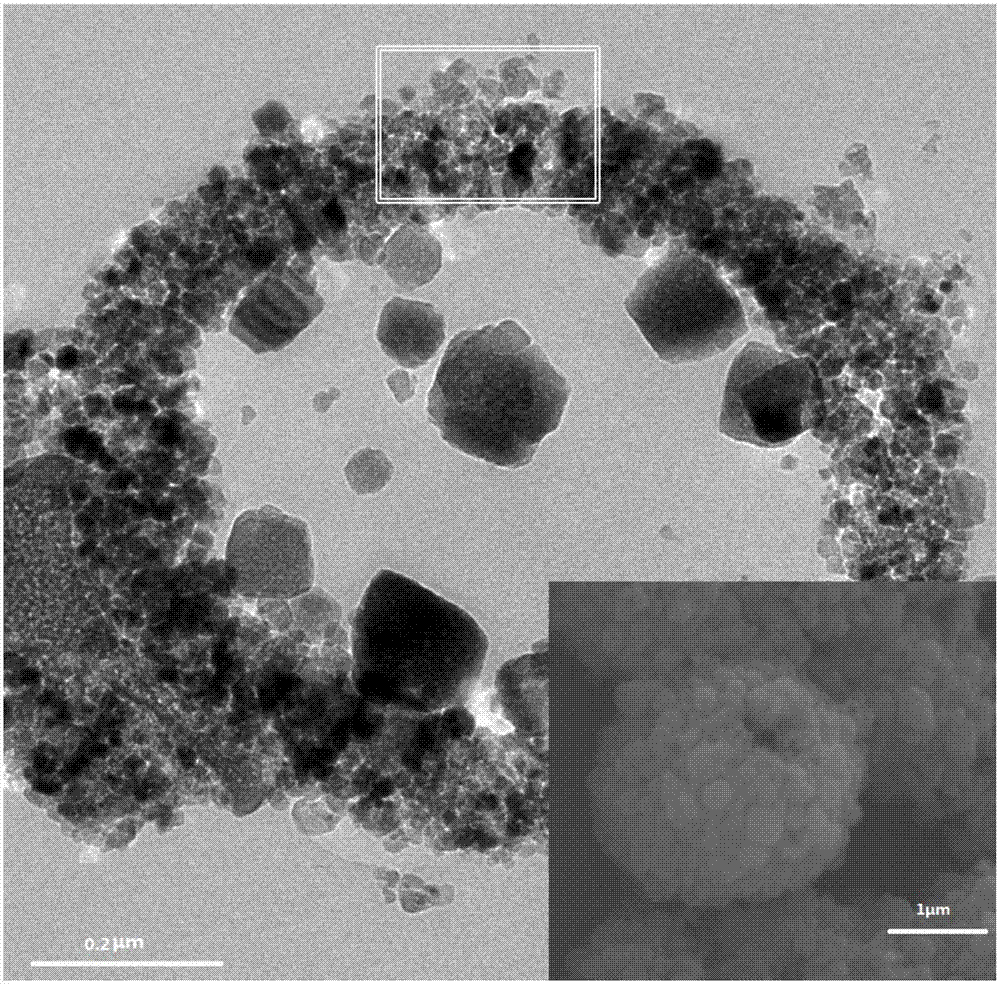

Embodiment 1

[0026] Add 1.0ml of ammonia water with a mass fraction of 25% in 300ml of absolute ethanol, add dropwise 4.4ml of tetrabutyl phthalate under magnetic stirring, age for 24 hours, centrifuge, and dry to obtain a titanium-containing precursor with a thickness of 800-810nm. Then weigh 0.2g of precursor and 0.508g of strontium nitrate, pour it into the inner lining of the reaction kettle, add 20ml of water and a certain amount of 0.8g / mL sodium hydroxide solution to make the pH equal to 14, stir for 15 minutes and place it at 185 Hydrothermal reaction in an oven at ℃, take out the reaction vessel after 2.5 hours, and cool to room temperature naturally, wash the obtained powder alternately with deionized water and dilute acetic acid, filter with suction, and finally dry in an oven at 60℃ to obtain hollow spherical structure titanium For the strontium titanate powder, the inner diameter of the hollow spherical strontium titanate powder is 0.6-0.8 μm, and the outer diameter of the holl...

Embodiment 2

[0028] Add 1.0ml of ammonia water with a mass fraction of 25% in 300ml of absolute ethanol, add 4.4ml of tetrabutyl phthalate dropwise under magnetic stirring, age for 22 hours, centrifuge, and dry to obtain a titanium-containing precursor of about 780-800nm . Then weigh 0.21g of precursor and 0.501g of strontium nitrate, pour it into the inner lining of the reaction kettle, add 20ml of water and a certain amount of 0.8g / mL sodium hydroxide solution to make the pH equal to 13.5, stir for 15 minutes and place it at 182 Hydrothermal reaction in an oven at ℃, take out the reaction vessel after 2.5 hours, and cool to room temperature naturally, wash the obtained powder alternately with deionized water and dilute acetic acid, filter with suction, and finally dry in an oven at 60℃ to obtain hollow spherical structure titanium For the strontium titanate powder, the inner diameter of the hollow spherical strontium titanate powder is 0.6-0.8 μm, and the outer diameter of the hollow sph...

Embodiment 3

[0030] Add 1.0ml of ammonia water with a mass fraction of 25% in 300ml of absolute ethanol, add 4.4ml of tetrabutyl phthalate dropwise under magnetic stirring, age for 18 hours, centrifuge, and dry to obtain a titanium-containing precursor of about 800-820nm . Then weigh 0.18g of precursor and 0.516g of strontium nitrate, pour it into the lining of the reaction kettle, add 20ml of water and a certain amount of 0.8g / mL sodium hydroxide solution to make the pH equal to 13.8, stir for 15 minutes and place it at 180 Hydrothermal reaction in an oven at ℃, take out the reaction vessel after 2.5 hours, and cool to room temperature naturally, wash the obtained powder alternately with deionized water and dilute acetic acid, filter with suction, and finally dry in an oven at 60℃ to obtain hollow spherical structure titanium For the strontium titanate powder, the inner diameter of the hollow spherical strontium titanate powder is 0.6-0.8 μm, and the outer diameter of the hollow spherical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com