Preparation method of colorless transparent polyimide film

A technology of transparent polyimide and polyamic acid, which is applied in the field of thin films, can solve the problems of low transmittance and limitation of visible light, achieve excellent optical transparency, prevent film yellowing, and improve optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

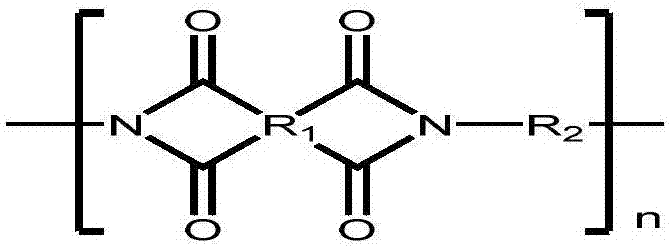

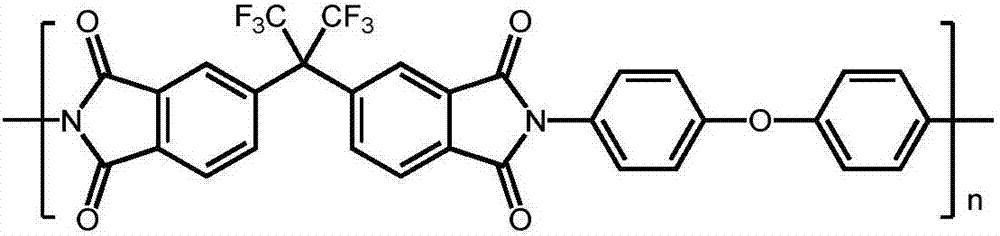

[0028] In this embodiment, the colorless transparent polyimide film material has the following structural formula:

[0029]

[0030] Concrete preparation steps are as follows:

[0031] (1) In a reaction kettle full of nitrogen protection gas, first dissolve 4,4'-diaminodiphenyl ether in DMAc solvent, then add hexafluoroisopropylidene tetraphthalic acid dianhydride, and the molar ratio of feeding is 1:1, polycondensation reaction with mechanical stirring at 25°C to obtain a polyamic acid solution with a rotational viscosity of 150,000mPa·s (25°C, Type B) and a solid content of 20%.

[0032] (2) At -15°C, add acetic anhydride (2 times the equivalent of aromatic diamine) and isoquinoline (1.5 times the equivalent of aromatic diamine) to the above polyamic acid solution, and stir thoroughly Dispersed, followed by defoaming treatment.

[0033] (3) The defoamed solution was cast onto a glass support, heated to 120° C. at a heating rate of 5° C. / min, and the imidization reaction...

Embodiment 2

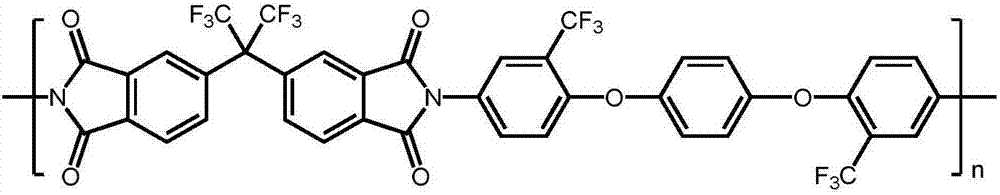

[0035] In this embodiment, the colorless transparent polyimide film material has the following structural formula:

[0036]

[0037] Concrete preparation steps are as follows:

[0038] (1) In a reactor filled with nitrogen protection gas, first dissolve 1,4-bis(4-amino-2-trifluoromethylphenoxy)benzene in NMP solvent, then add hexafluoroisopropylidene Pyellitic dianhydride, the molar ratio of feed is 1:1, and the polycondensation reaction is mechanically stirred at 25°C to obtain a polyamic acid solution with a rotational viscosity of 125000mPa·s (25°C, Type B) and a solid content of 18%.

[0039] (2) At -10°C, add acetic anhydride (3 times the equivalent of aromatic diamine) and isoquinoline (1.5 times the equivalent of aromatic diamine) to the above polyamic acid solution, and stir thoroughly Dispersed, followed by defoaming treatment.

[0040] (3) The defoamed solution was cast onto a glass support, and heated to 130° C. at a heating rate of 5° C. / min to fully volatiliz...

Embodiment 3

[0042] In this embodiment, the colorless transparent polyimide film material has the following structural formula:

[0043]

[0044] Concrete preparation steps are as follows:

[0045] (1) In a reactor filled with nitrogen protection gas, first dissolve 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl in DMAc solvent, then add hexafluoroisopropylidene Tetraacid dianhydride, the feeding molar ratio is 1:1, the polyamic acid solution is obtained with mechanical stirring at 25°C for 6h, and the rotational viscosity is 100000mPa·s (25°C, type B), and the solid content is 15%.

[0046] (2) At -10°C, add acetic anhydride (the amount is 2.5 times the equivalent of the aromatic diamine) and isoquinoline (the amount is 2 times the equivalent of the aromatic diamine) to the above polyamic acid solution, and stir thoroughly Dispersed, followed by defoaming treatment.

[0047] (3) The defoamed solution was cast onto a glass support, and heated to 120° C. at a heating rate of 10° C. / min t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com