Ethylene propylene diene rubber for absorbing shock of automobile engine and preparation method thereof

A technology of EPDM rubber and automobile engines, which is applied in the field of rubber, can solve the problems of poor high temperature resistance, short service life of parts, large high temperature compression deformation, etc., and achieve fast vulcanization speed, low high temperature compression deformation, and large molecular weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

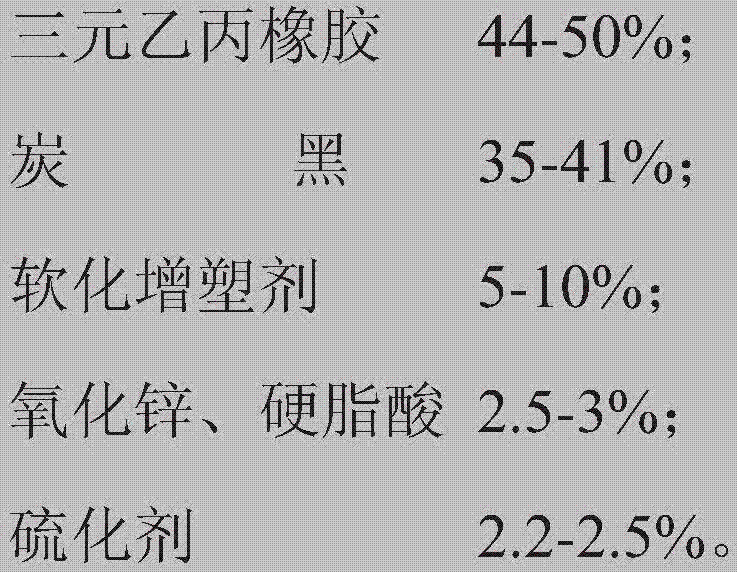

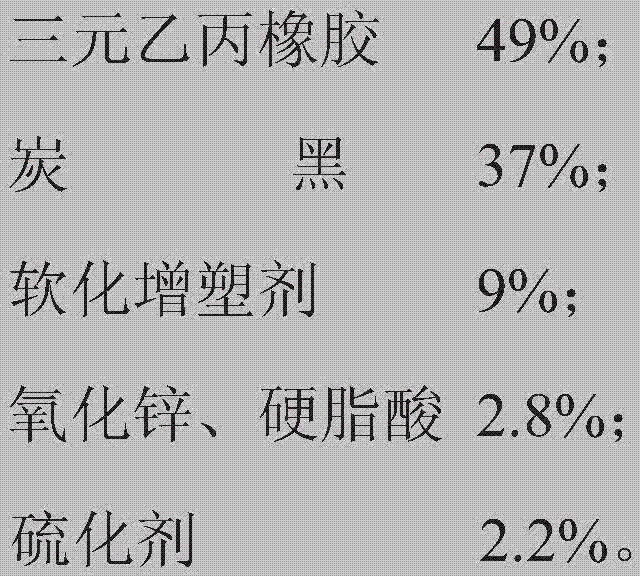

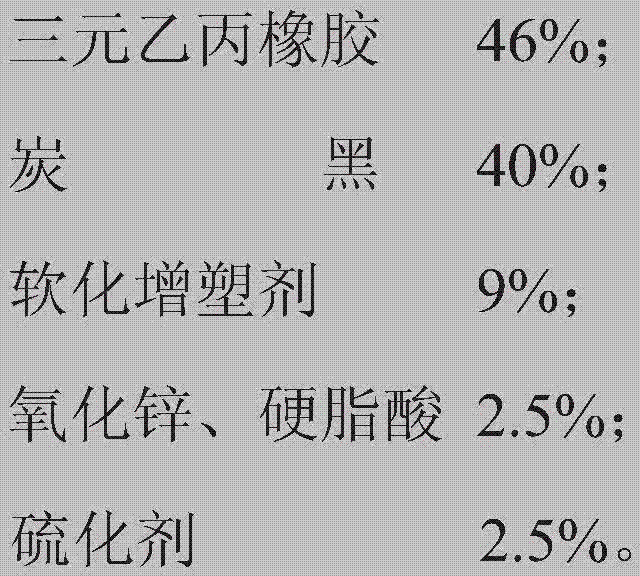

[0028] According to the composition ratio in Table 1, the production of rubbers for automobile engine shock absorbers in Examples 1-6 was carried out.

[0029] Manufacture the EPDM rubber for automobile engine shock absorber of the present invention according to the following steps:

[0030] (1) Preparation of materials: According to the ingredients and proportions in Table 1, EPDM rubber, carbon black, softening plasticizer, active agent zinc oxide, and stearic acid were weighed and mixed to form ingredient A, and vulcanizing agent Weigh to form ingredient B;

[0031] (2) The first mixing: Put ingredient A into the internal mixer for 60-90 seconds, lift the hammer to clean, then press the hammer to mix for 60-90 seconds, lift the hammer to clean again (temperature 140-150°C), and then press the hammer Mix for 60-80 seconds and unload (temperature 150-170°C) to the cutting machine to discharge the sheet to make rubber compound A;

[0032] (3) The second mixing: Put the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com