Water-based polymer isocyanate wood adhesive and preparation method thereof

A wood adhesive, water-based polymer technology, used in adhesives, polyurea/polyurethane adhesives, adhesive types, etc., can solve problems affecting the environment and users' health, improve compatibility, and enhance wet bonding Strength and water and weather resistance and aging resistance, the effect of prolonging the pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

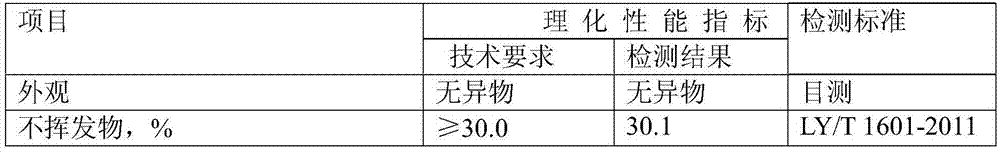

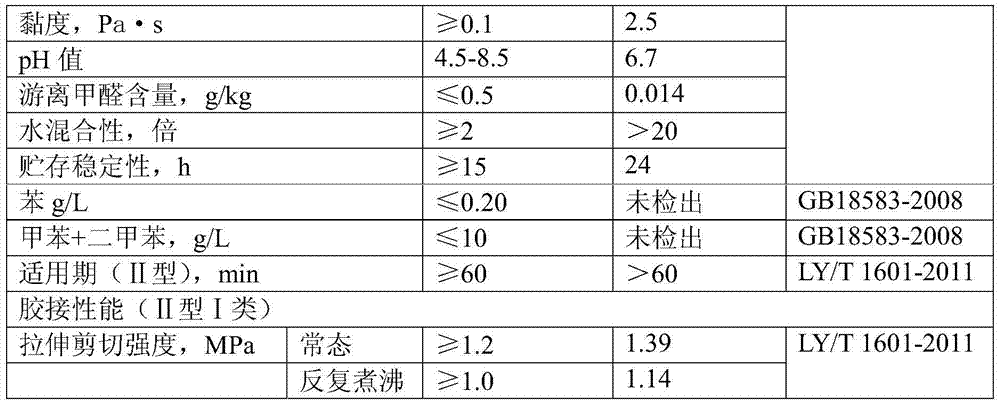

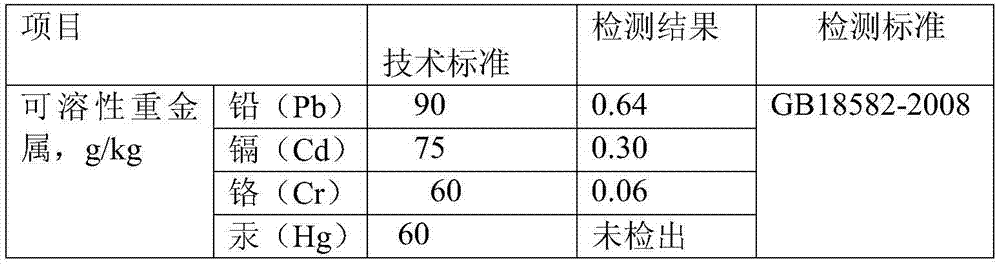

Examples

Embodiment 1

[0051] 1. Adhesive formula:

[0052] Main ingredient: polyvinyl alcohol, 10 parts;

[0053] Composite polyol (made by mixing soybean oil polyol, castor oil and polyol benzoate in a weight ratio of 10:10:80), 6 parts;

[0054] 22 parts of silica sol;

[0055] Filler (titanium dioxide), 12 parts;

[0056] water, 50 parts;

[0057] Surfactant (sodium dodecylbenzenesulfonate), 0.1 part;

[0058] Defoamer (n-butanol), 0.1 part;

[0059] Preservative (isothiazolinone), 0.1 part;

[0060]Cross-linking agent: (polyphenyl polymethylene polyisocyanate), its consumption is 15% of the main agent.

[0061] 2. Preparation method:

[0062] 1) Weigh each component according to the formula, and set aside;

[0063] 2) First add water to the reaction kettle with a heating stirrer, add polyvinyl alcohol and defoamer, heat up to 93°C and keep warm until the polyvinyl alcohol is completely dissolved, then cool the system down to 70°C, add surfactant, keep warm Stir and react for 40 minutes...

Embodiment 2

[0072] 1. Adhesive formula:

[0073] Main ingredient: polyvinyl alcohol, 12 parts;

[0074] Complex polyol (composed of castor oil and polyol benzoate in a weight ratio of 1:4), 3 parts;

[0075] 22 parts of silica sol;

[0076] Filler (composed of calcium carbonate and talc in a weight ratio of 1:1), 8 parts;

[0077] water, 55 parts;

[0078] Surfactant (sodium dodecylbenzenesulfonate), 0.2 part;

[0079] Defoamer (tributyl phosphate), 0.05 parts;

[0080] Preservative (isothiazolinone), 0.05 part;

[0081] Cross-linking agent: 1,6-hexamethylene diisocyanate, its dosage is 10% of the main agent.

[0082] 2. Preparation method:

[0083] 1) Weigh each component according to the formula, and set aside;

[0084] 2) First add water to the reaction kettle with a heating stirrer, add polyvinyl alcohol and defoamer, heat up to 95°C and keep warm until the polyvinyl alcohol is completely dissolved, then cool the system down to 65°C, add surfactant, keep warm Stir and react f...

Embodiment 3

[0090] 1. Adhesive formula:

[0091] Main ingredient: polyvinyl alcohol, 9 parts;

[0092] Composite polyol (obtained by mixing soybean oil polyol, castor oil and polyol benzoate in a weight ratio of 15:15:50), 4 parts;

[0093] 18 parts of silica sol;

[0094] Filler (composed of kaolin and talc in a weight ratio of 2:1), 9 parts;

[0095] water, 60 parts;

[0096] Surfactant (sodium dodecylbenzenesulfonate), 0.05 part;

[0097] Defoamer (composed of n-butanol and tributyl phosphate in a weight ratio of 1:1), 0.15 parts;

[0098] Preservative (isothiazolinone), 0.2 parts;

[0099] Crosslinking agent: diphenylmethane diisocyanate, its consumption is 20% of the main agent.

[0100] 2. Preparation method:

[0101] 1) Weigh each component according to the formula, and set aside;

[0102] 2) First add water to the reaction kettle with a heating agitator, add polyvinyl alcohol and defoamer, heat up to 92°C and keep warm until the polyvinyl alcohol is completely dissolved, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com