Bench-type laser precision washing device with dual-wavelength composite energy distribution

A technology of compound energy and cleaning device, applied in the field of laser cleaning, can solve the problems of poor precision, low cleaning efficiency, pollution, etc., and achieve the effect of enhancing uniformity and fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

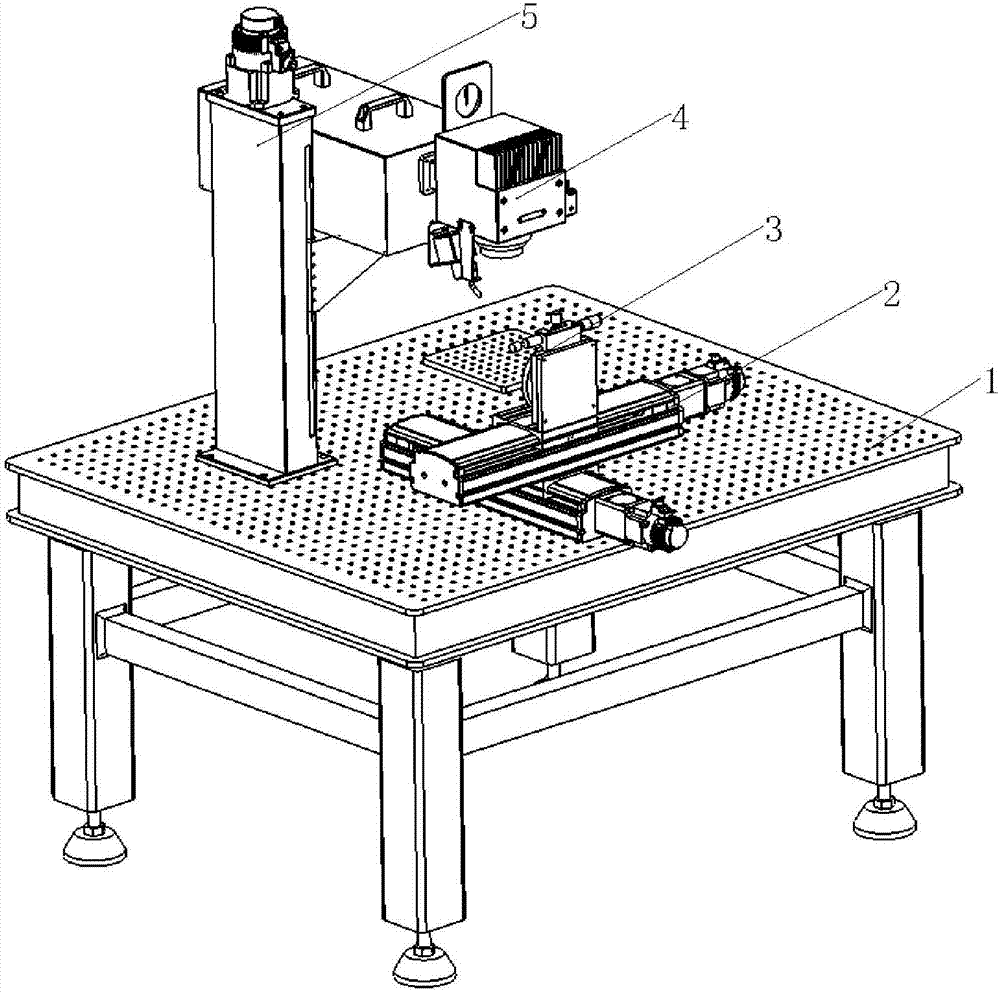

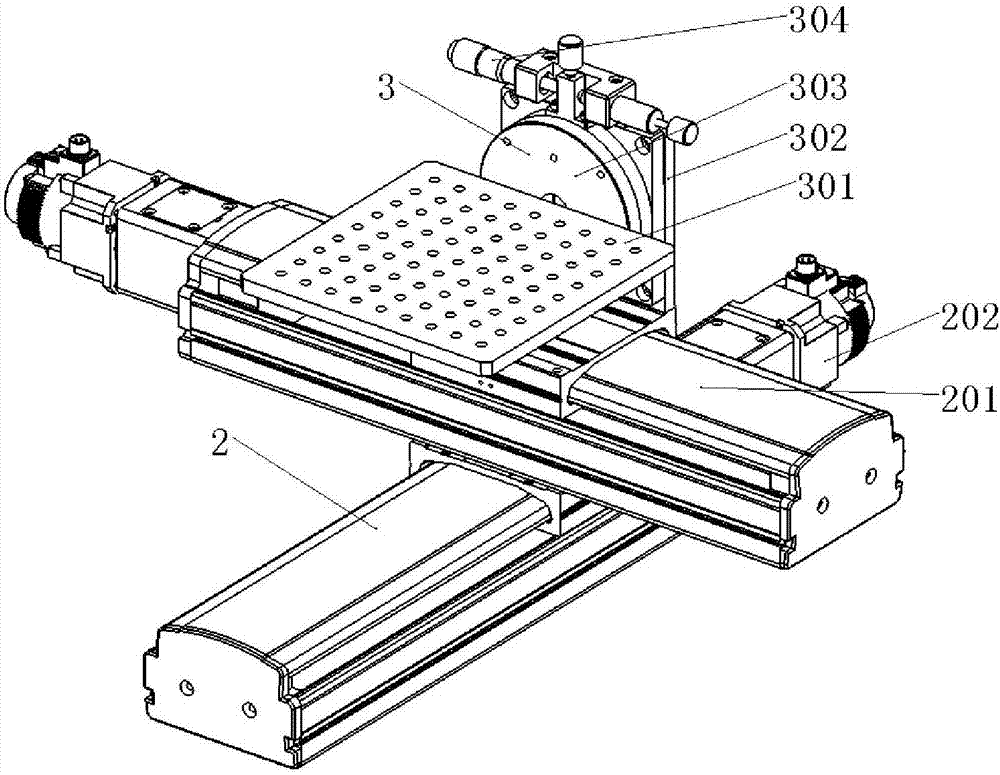

[0045] Such as Figure 1-7 As shown, the present invention provides a desktop laser precision cleaning device with dual-wavelength composite energy distribution, including a worktable 1, an X-Y electric module 2, a rotary table assembly 3, a laser cleaning assembly 4 and a Z-direction lifting table 5.

[0046] The X-Y electric module 2 is fixedly installed on the workbench 1, and the rotary table assembly 3 is installed on the X-Y electric module 2, which can be driven by the X-Y electric module 2 to perform X-Y two-dimensional plane movement.

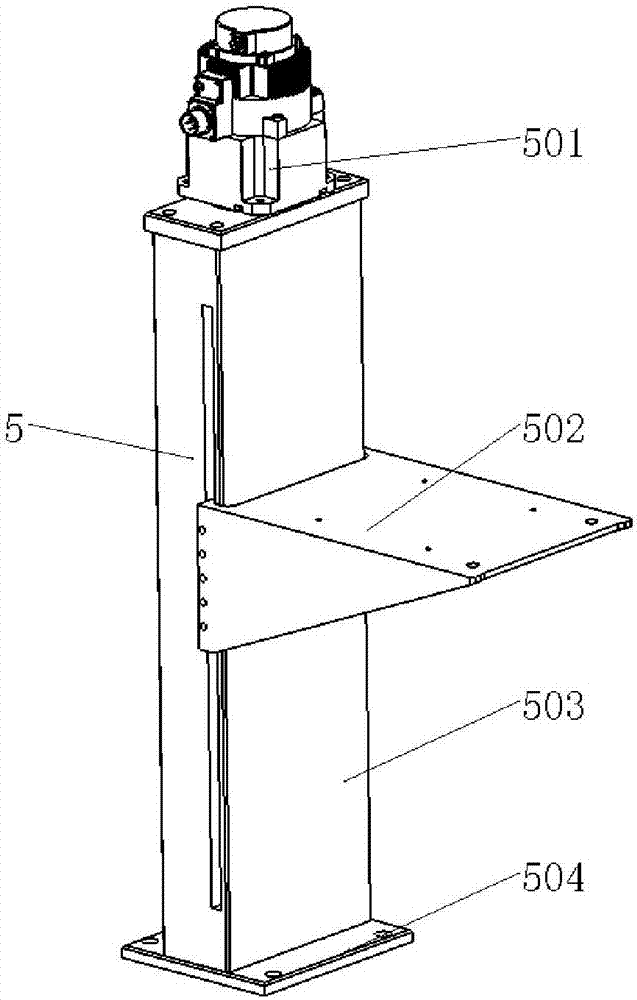

[0047] The Z-direction lifting platform 5 is installed on the workbench 1, the laser cleaning assembly 4 is installed on the lifting plate 502 of the Z-direction lifting platform 5, and is located above the rotating table assembly 3, and the laser cleaning assembly 4 can be driven by the lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com