Integral type combustion catalyst with multiple active centers

A monolithic catalyst and active center technology, applied in catalyst activation/preparation, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve problems such as incomplete oxidation, low light-off temperature, and poor thermal stability. Achieve the effects of cheap and easy to obtain coating raw materials, reduced application costs, and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 2.416g of Cu(NO 3 ) 2 ·3H2 O, 7.158g of 50wt% Mn(NO 3 ) 2 Aqueous solution, 17.365g of Ce(NO 3 ) 3 ·6H 2 O, 12.880g of Zr(NO 3 ) 4 ·5H 2 0, add deionized water to dissolve, be mixed with metal ion Cu:Mn:Ce:Zr molar ratio is 1:2:4:3, and total concentration is 100ml of the solution of 1.0mol / L.

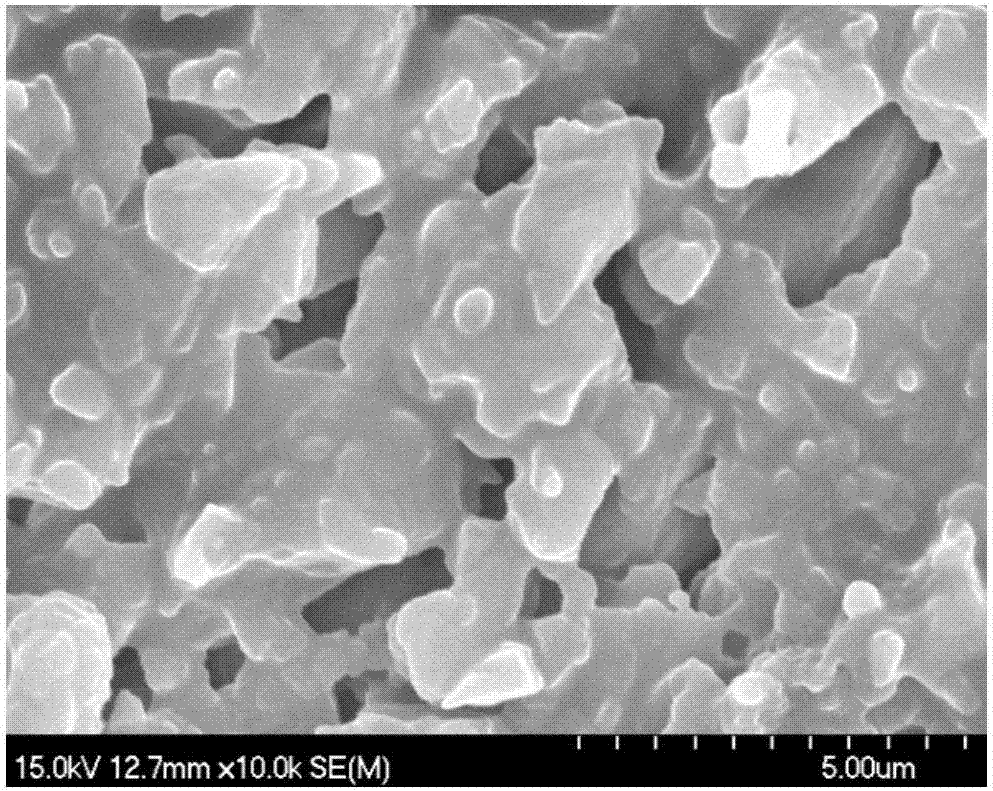

[0032] The preprocessed size is 8.83cm 3 After the cylindrical cordierite honeycomb ceramics were immersed in 10ml of the above CMCZ solution for 30min, the remaining liquid on the surface and in the pores was blown off with a blower, dried at 110°C for 2h, and fired at 500°C for 3h to obtain a cordierite ceramic with a CMCZ loading of 4.0%. , recorded as CMCZ / CH-1.

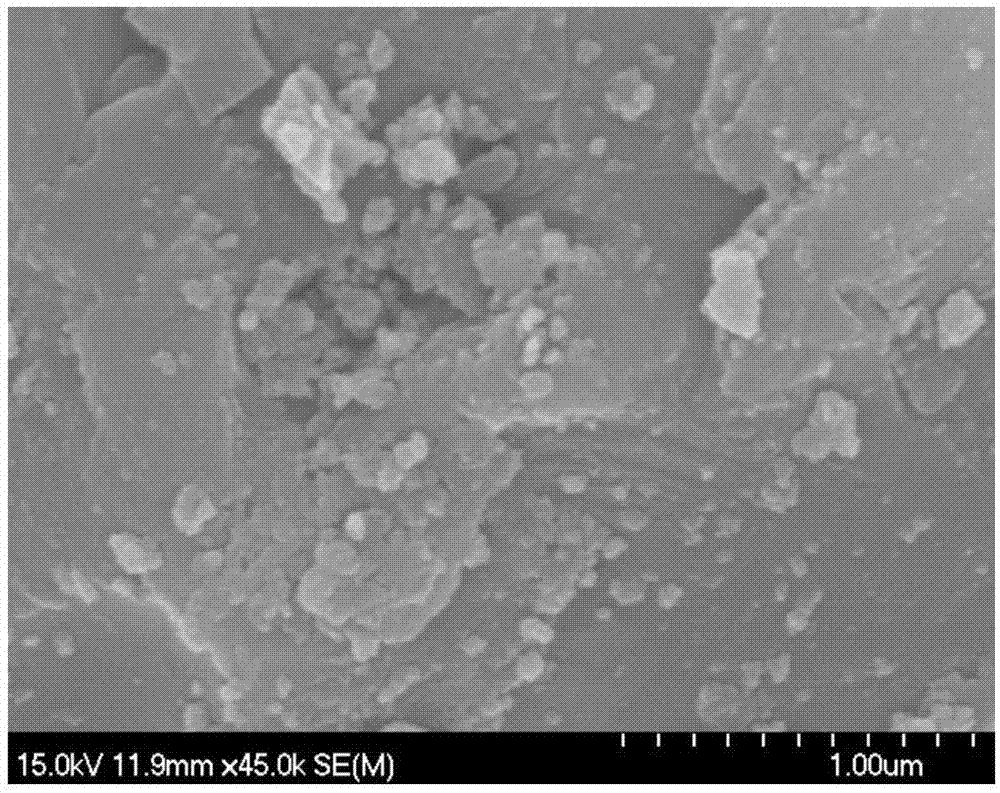

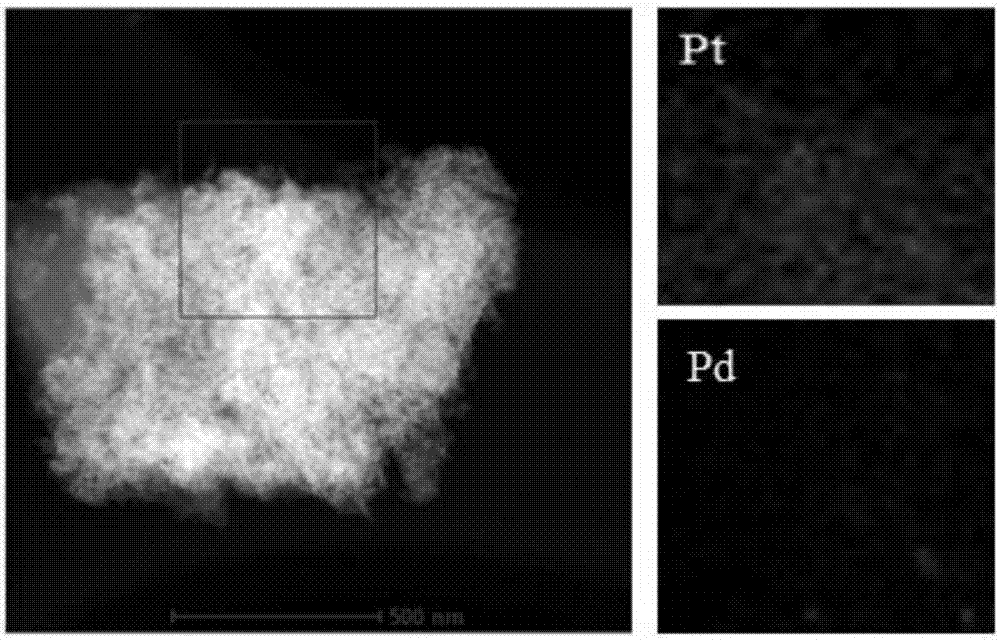

[0033] The above CMCZ / CH-1 catalyst was impregnated in 10 ml of H 2 PtCl 6 ·6H 2 O and PdCl 2 In the mixed solution, absorb in a water bath at 70°C for 2 hours, take it out and blow off the residual solution in the pores, dry at 110°C for 2 hours, and roast at 500°C for 3 hours. The obtained mon...

Embodiment 2

[0035] Weigh 2.416g Cu(NO 3 ) 2 ·3H 2 O, 10.737g of 50wt% Mn(NO 3 ) 2 Aqueous solution, 13.024g of Ce(NO 3 ) 3 ·6H 2 O, 12.880g of Zr(NO 3 ) 4 ·5H 2 0, add deionized water to dissolve, be mixed with metal ion Cu:Mn:Ce:Zr molar ratio is 1:3:3:3, and total concentration is 100ml of the solution of 1.0mol / L.

[0036] The preprocessed size is 8.83cm 3 After immersing cylindrical cordierite honeycomb ceramics in 10ml of the above CMCZ solution for 30min, take it out and blow off the remaining liquid on the surface and in the pores with a blower, dry at 110°C for 2h, and bake at 500°C for 3h to obtain a CMCZ loading capacity of 3.8%. Cordierite ceramics, denoted as CMCZ / CH-2.

[0037] The above CMCZ / CH-2 catalyst was impregnated in 10 ml of H 2 PtCl 6 ·6H 2 O and PdCl 2 In the mixed solution, after adsorbing in a water bath at 70°C for 2 hours, take it out and blow off the residual solution in the pores, dry it at 110°C for 2 hours, and roast it at 500°C for 3 hours. ...

Embodiment 3

[0039] Weigh 2.416g Cu(NO 3 ) 2 ·3H 2 O, 14.316g of 50wt% Mn(NO 3 ) 2 Aqueous solution, 9.682g of Ce(NO 3 ) 3 ·6H 2 O, 12.880g of Zr(NO 3 ) 4 ·5H 2 0, add deionized water to dissolve, be mixed with metal ion Cu:Mn:Ce:Zr molar ratio is 1:4:2:3, and total concentration is 100ml of the solution of 1.0mol / L.

[0040] The preprocessed size is 8.83cm 3 After immersing cylindrical cordierite honeycomb ceramics in 10ml of the above CMCZ solution for 30min, take it out and blow off the remaining liquid on the surface and in the pores with a blower, dry at 110°C for 2h, and bake at 500°C for 3h to obtain a CMCZ loading capacity of 3.8%. Cordierite ceramics, denoted as CMCZ / CH-3.

[0041] The above CMCZ / CH-3 catalyst was impregnated in 10 ml of H 2 PtCl 6 ·6H 2 O and PdCl 2 In the mixed solution, after adsorbing in a water bath at 70°C for 2 hours, take it out and blow off the residual solution in the pores, dry it at 110°C for 2 hours, and roast it at 500°C for 3 hours. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com