Nitrogen-doped carbon material-supported palladium-based catalyst as well as preparation method and application thereof

A technology of carbon materials and nitrogen doping, applied in chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve the problems of expensive raw materials, complicated preparation, lack of research on doped nitrogen species, etc., to achieve Simple operation, easy operation, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add 3.35g of diethylenetriamine (a) and 5.0g of carbon tetrachloride into a round bottom flask containing 0.5g of SBA15, heat up to 90ºC and reflux for 4h to obtain a brown solid, put it in an oven for 100ºC to dry for 12h, put Put it into a tube furnace and heat up to 400ºC at 2.5ºC / min in a nitrogen atmosphere to polymerize for 4 hours. After cooling to room temperature, remove the template with 8 wt % hydrofluoric acid, wash and dry, and obtain a black nitrogen-doped carbon material NC-a -400.

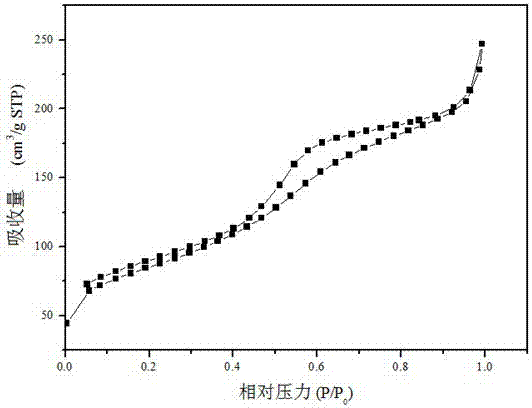

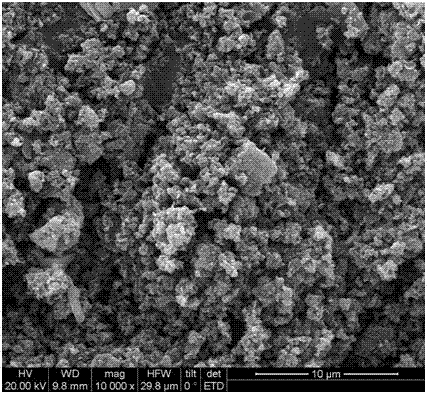

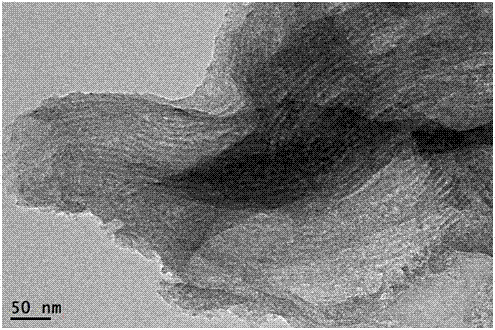

[0044] Analyze the relevant performance parameters of the nitrogen-doped carbon material NC-a-400, such as Figure 1~7 shown. The specific surface area of the nitrogen-doped carbon material NC-a-400 is 296m 2 / g, the pore volume is 0.35cm 3 / g, the pore size is 4.6nm; SEM figure shows that from the XPS peak fitting figure of N1s, it can be seen that there are mainly two types of N, which are pyridine nitrogen at 398.3 eV and pyrrole nitrogen at 400.4 eV nitrogen.

[00...

Embodiment 2

[0048] Add 4.77g of triethylenetetramine (b) and 5.0g of carbon tetrachloride into a round bottom flask containing 0.5g of SBA15, raise the temperature to 100ºC and reflux for 4h to obtain a dark brown solid, put it in an oven and dry it at 100ºC for 12h. Put it into a tube furnace and heat up to 500ºC at 3.0ºC / min in a nitrogen atmosphere to polymerize for 4 hours. After cooling to room temperature, remove the template with 8 wt % hydrofluoric acid, wash and dry, and obtain a black nitrogen-doped carbon material NC- b-500.

[0049] In a 250 ml round bottom flask, add 0.5 g of the new nitrogen-doped carbon material NC-b-500, 100 ml of absolute ethanol, ultrasonically shake for 20 min, add PdCl containing 20 mg of palladium 2 solution, ultrasonically oscillated for 20 min, heated to reflux and stirred for 12 h, added 15 ml 1 M / L NaBH 4 , continue to stir for 1h, cool, filter, wash, and vacuum-dry to obtain the palladium catalyst Pd / NC-b-500 supported by the novel nitrogen-dope...

Embodiment 3

[0052] Add 6.2g of tetraethylenepentamine (c) and 5.0g of carbon tetrachloride into a round-bottomed flask containing 0.5g of SBA15, heat up to 110ºC and reflux for 5h to obtain a dark brown solid, which is dried in an oven at 100ºC for 12h. Put it into a tube furnace and heat up to 600ºC at 4.0ºC / min in a nitrogen atmosphere to polymerize for 5 hours. After cooling to room temperature, remove the template with 8 wt % ammonium fluoride, wash and dry, and obtain a new black nitrogen-doped carbon material NC -c-600.

[0053] In a 250 ml round bottom flask, add 0.5 g of the new nitrogen-doped carbon material NC-c-600, 100 ml of propanol, ultrasonically shake for 20 min, add PdCl containing 30 mg of palladium 2 solution, ultrasonically oscillated for 20 min, heated to reflux and stirred for 12 h, added 20ml 1 M / L NaBH 4 , continue to stir for 1 h, cool, filter, wash, and vacuum-dry to obtain palladium catalyst Pd / NC-c-600 supported by a novel nitrogen-doped carbon material. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com