A processing technology and device for improving nutrition of rice

A processing technology and processing device technology, which is applied in the field of rice processing, can solve the problems of insufficient nutrition and excessive broken rice, and achieve the effects of constant water temperature, reduced brokenness, and prevention of excessive evaporation and unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A processing technology for improving rice nutrition, comprising the following steps:

[0033] S1: drying: drying the rice in the sun for one day;

[0034] S2: Impurity removal: Put the dried rice into the destoner machine for screening and destoner, and then put it into the permanent magnetic cylinder to remove impurities;

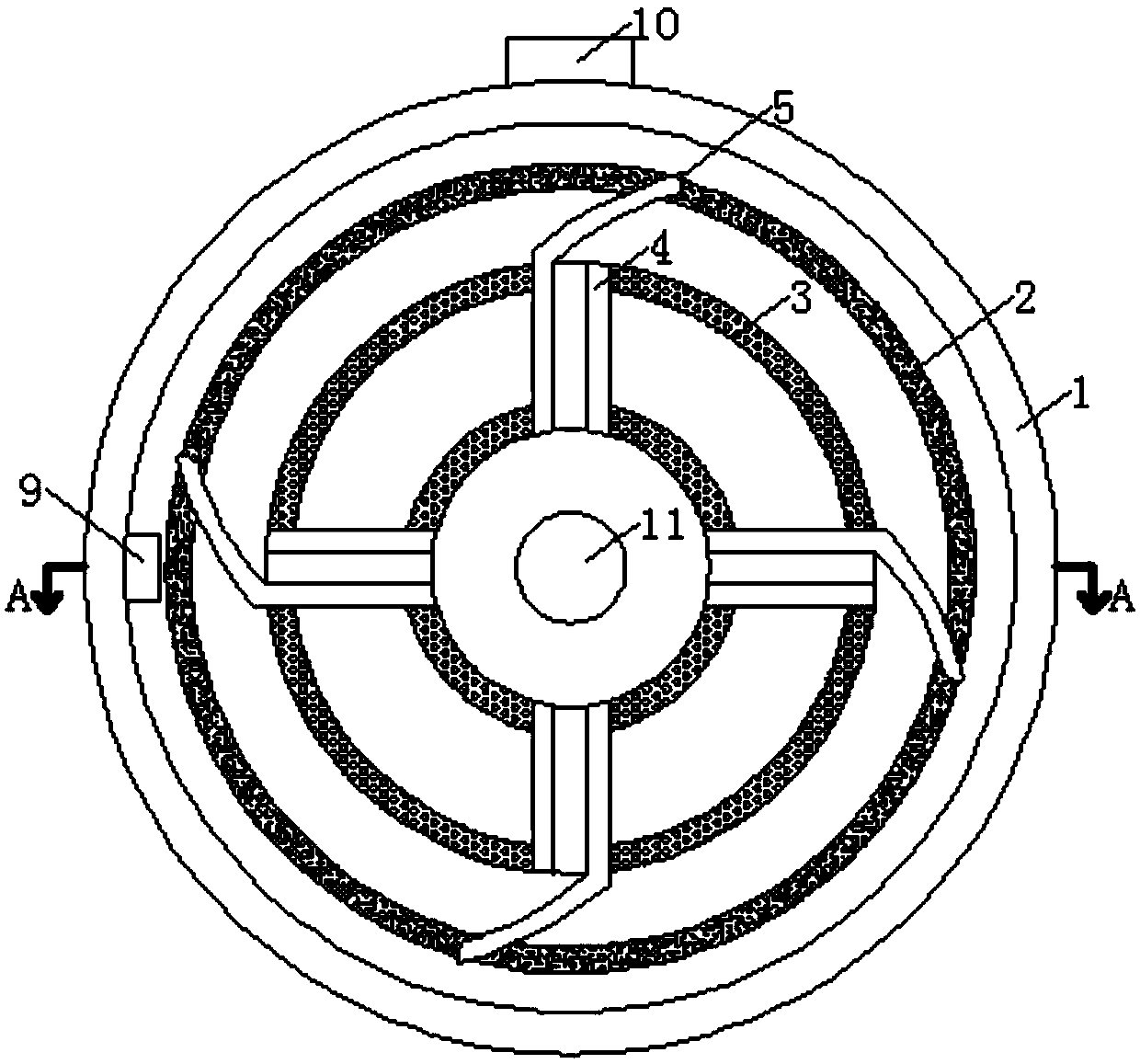

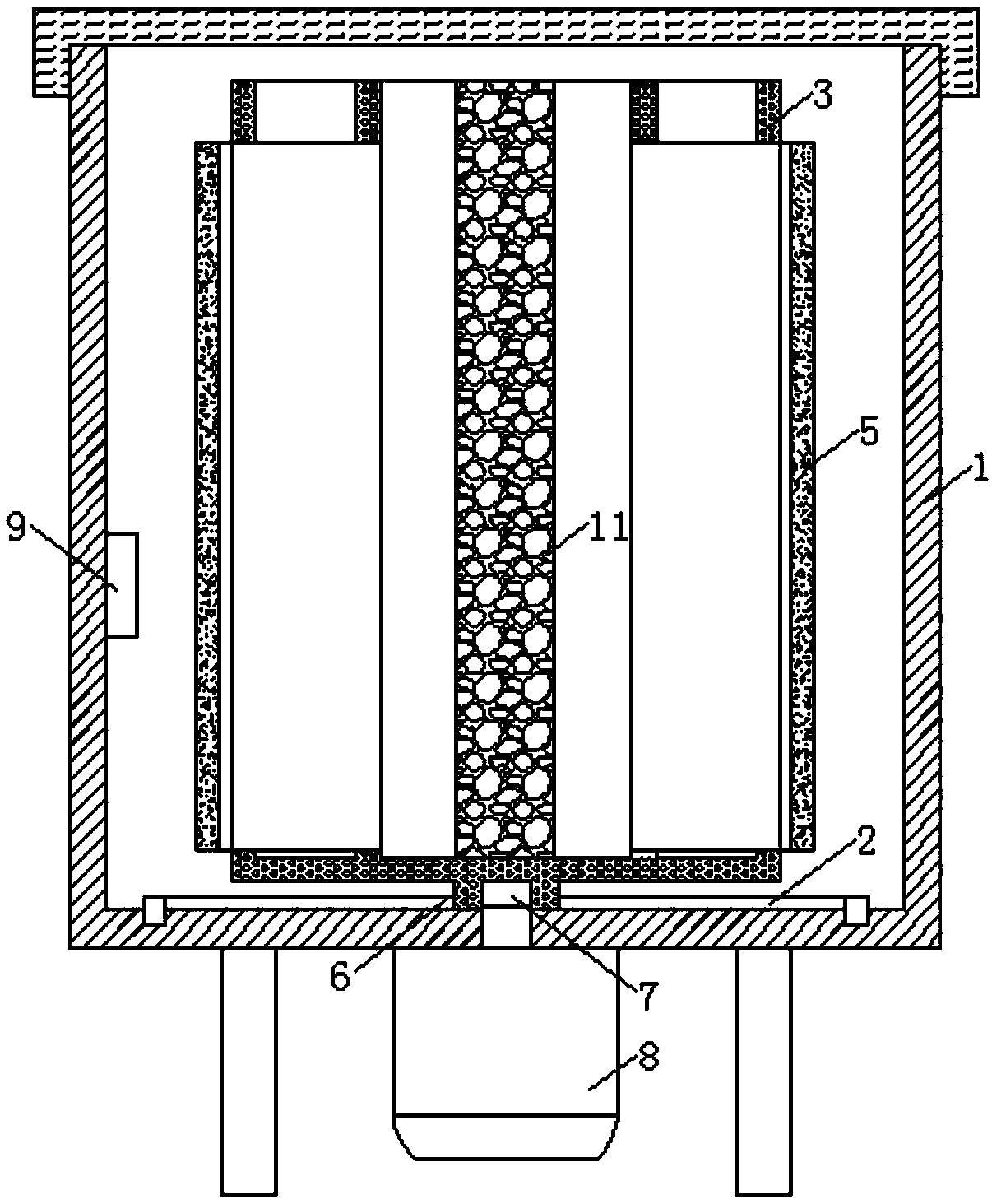

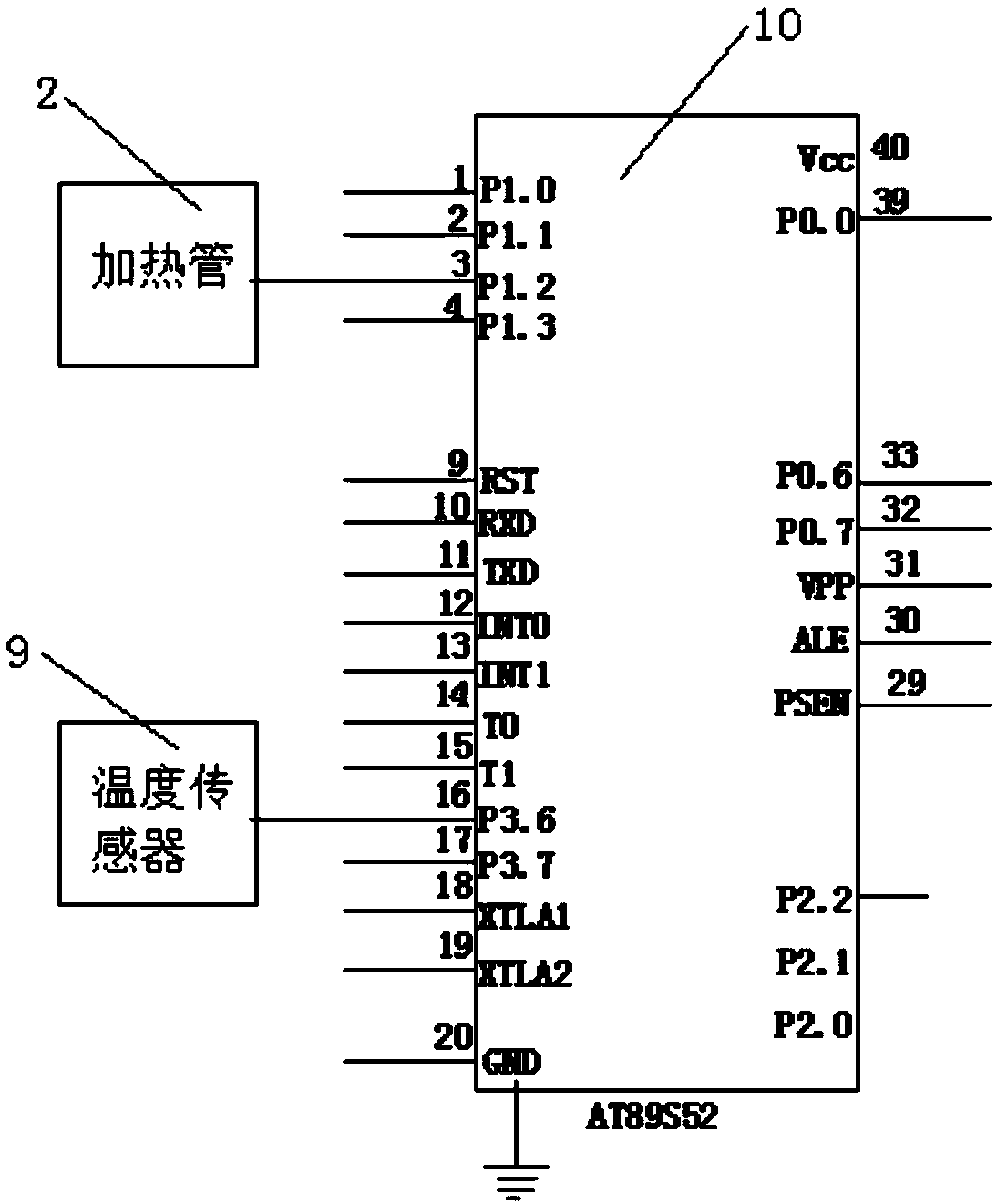

[0035] S3: Soaking: put the impurity-removed rice in the heat preservation device for soaking, and the water absorption rate reaches 20%;

[0036] S4: heat preservation: keep the soaked rice at 30°C for 10 hours, then put it into the drying room for intermittent drying, take it out after drying for 40 minutes each time, cool for 15 minutes, and then continue drying until the water content is 12%;

[0037] S5: Rice milling: put the rice kept warm in step S4 into a rice mill for shelling, the shelling rate reaches 70%, and a semi-finished product is obtained. The shelling machine is a rubber roller huller, and the shelling effect is better;

[0038...

Embodiment 2

[0048] A processing technology for improving rice nutrition, comprising the following steps:

[0049] S1: drying: drying the rice in the sun for one day;

[0050] S2: Impurity removal: Put the dried rice into the destoner machine for screening and destoner, and then put it into the permanent magnetic cylinder to remove impurities;

[0051] S3: Soaking: Put the impurity-removed rice in the heat preservation device for soaking, and the water absorption rate reaches 30%;

[0052] S4: heat preservation: keep the soaked rice at 35°C for 10 hours, then put it into the drying room for intermittent drying, take it out after drying for 50 minutes each time, cool for 15 minutes, and then continue drying until the water content is 14%;

[0053]S5: Rice milling: put the rice kept warm in step S4 into a rice mill for shelling, the shelling rate reaches 70%, and a semi-finished product is obtained. The shelling machine is a rubber roller huller, and the shelling effect is better;

[0054]...

Embodiment 3

[0064] A processing technology for improving rice nutrition, comprising the following steps:

[0065] S1: drying: drying the rice in the sun for one day;

[0066] S2: Impurity removal: Put the dried rice into the destoner machine for screening and destoner, and then put it into the permanent magnetic cylinder to remove impurities;

[0067] S3: Soaking: put the impurity-removed rice in the heat preservation device for soaking, and the water absorption rate reaches 25%;

[0068] S4: heat preservation: keep the soaked rice at 33°C for 10 hours, then put it into the drying room for intermittent drying, take it out after drying for 45 minutes each time, cool it for 15 minutes, and then continue drying until the water content is 13%;

[0069] S5: Rice milling: put the rice kept warm in step S4 into a rice mill for shelling, the shelling rate reaches 70%, and a semi-finished product is obtained. The shelling machine is a rubber roller huller, and the shelling effect is better;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com