Method for rapid solvent-free preparation of heteroatom-doped graphitized carbon with high specific surface area

A high specific surface area, graphitized carbon technology, applied in the preparation/purification of carbon, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of large solvent usage, cumbersome steps, high cost, etc., and achieve simple operation and rich surface The effect of short structure and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

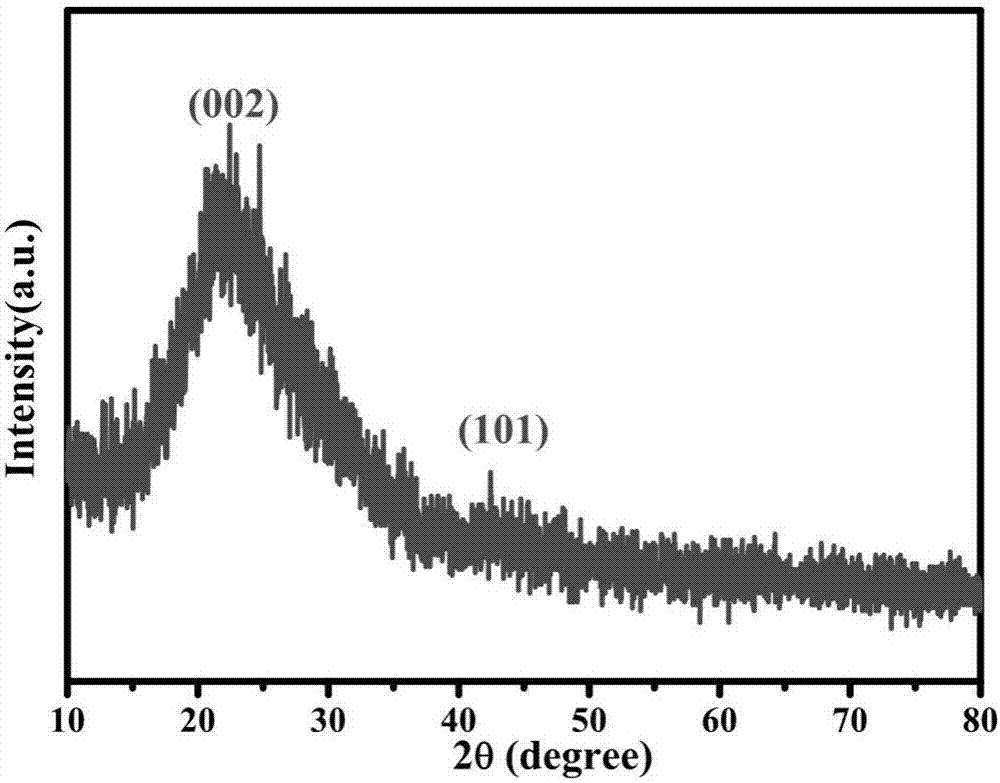

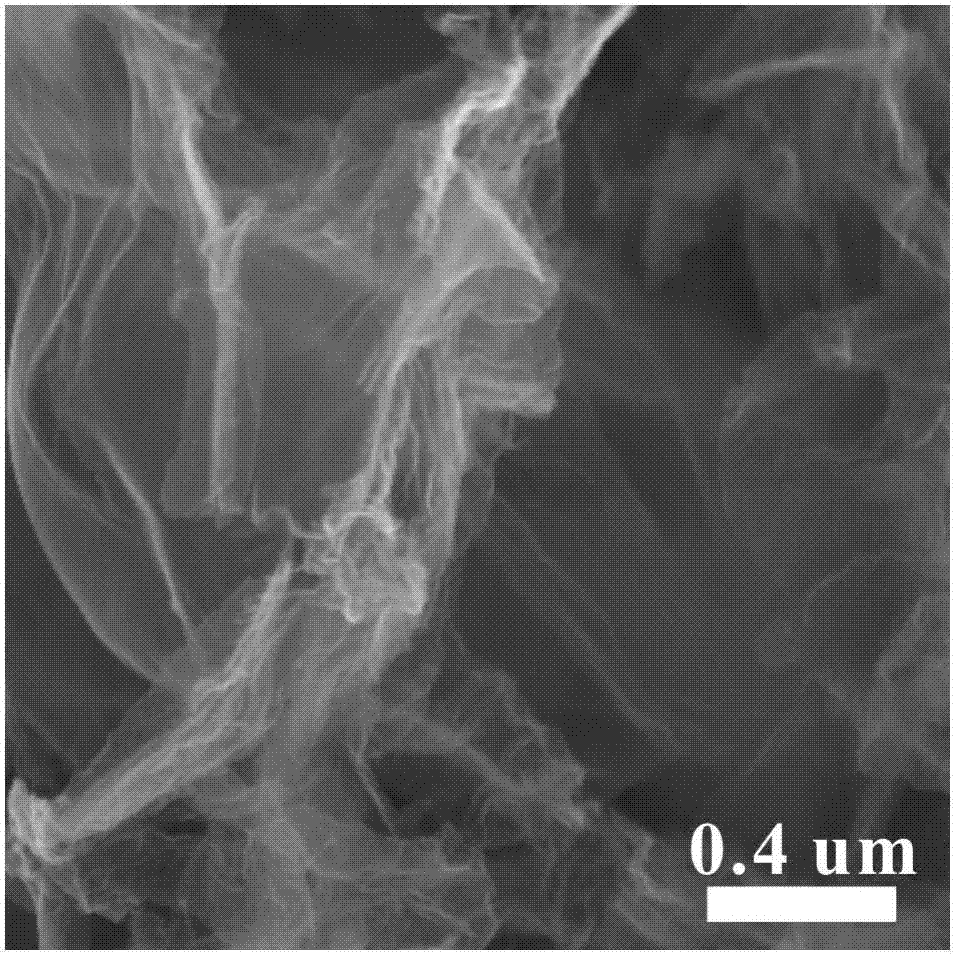

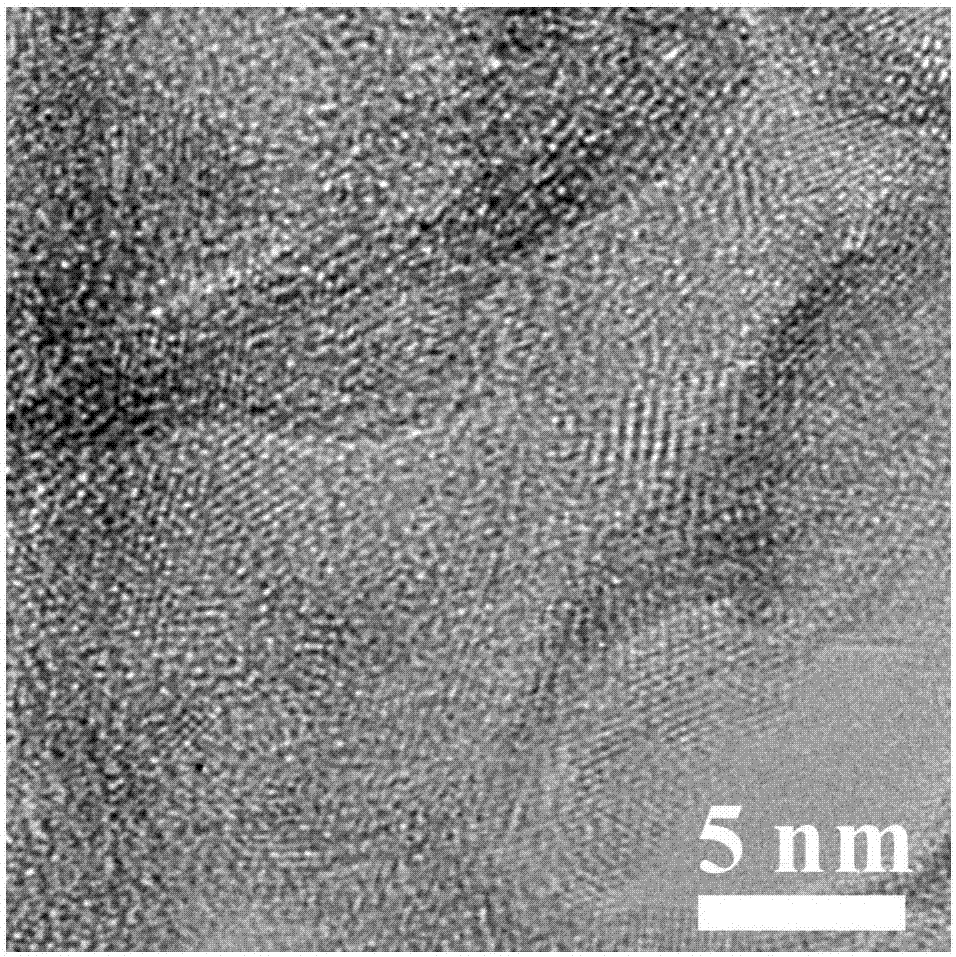

Embodiment 1

[0032] Grind 1g of metaldehyde yellow solid with 10g of sodium benzenesulfonate, place it in a porcelain boat, seal it, and calcinate at 1000°C for 2 hours under the protection of argon, with a heating rate of 5°C per minute. After the reaction, cool, wash, and dry , to obtain high specific surface area graphitized carbon doped with about 200 mg of sulfur atoms. figure 1 It is its XRD picture, it can be observed that the sulfur atom-doped high specific surface area graphitized carbon prepared by this method has an obvious carbon diffraction peak on the (001) crystal plane. figure 2 It is its scanning electron microscope photo, and it can be seen that the high specific surface area graphitized carbon doped with sulfur atoms is composed of many nanometer ultrathin sheets. image 3 A high-resolution transmission electron microscope picture of the obtained sulfur atom-doped graphitized carbon with high specific surface area is shown, and a layer of obvious lattice stripes can als...

Embodiment 2

[0039] Mix and grind 500mg of sodium dodecylbenzenesulfonate and 2000mg of polyacetone, place it in a tube furnace at 1100°C in an argon atmosphere for 2 hours, and react for 2h with a heating rate of 2°C / min to obtain about 50mg of the product. The sulfur-doped graphitized carbon has a specific surface area of 968.5m 2 g -1 , and its sulfur content is 3.2%.

Embodiment 3

[0043] Mix and grind 2g of sodium phenylphosphonate and 8g of polyacetone, place it in a tube furnace, raise the temperature at 10°C / min to 1200°C in an argon atmosphere for 1 hour, and obtain about 100mg of phosphorus-doped high Specific surface area of graphitized carbon, XPS results show that its phosphorus content is 8.6%, and its specific surface area is 687.6m 2 g -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com