Method for separation and purification of monomethylamine-dimethylamine mixture in methylamine synthesis system

A technology of monomethylamine dimethylamine and dimethylamine, applied in the field of separation, can solve the problems of loss of DMF products, increase of equipment investment, steam consumption, etc., to reduce the loss of dimethylamine, low equipment investment cost, and economic benefits high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

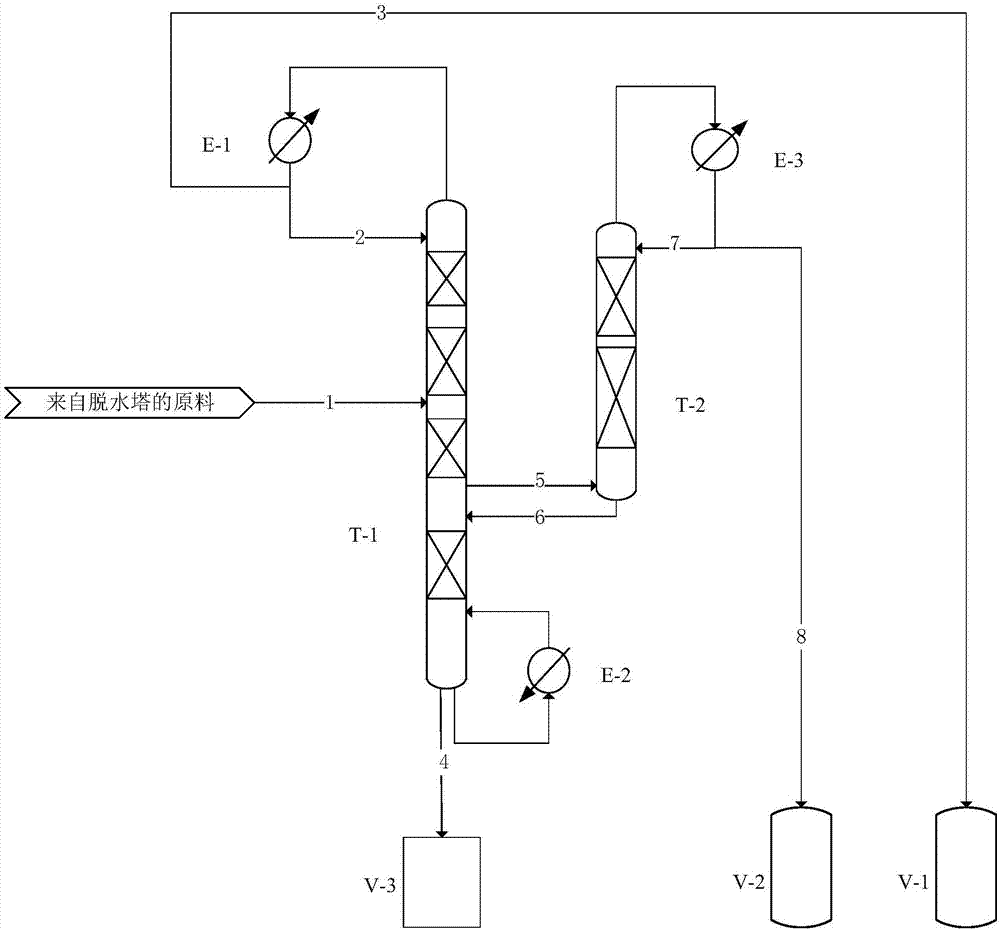

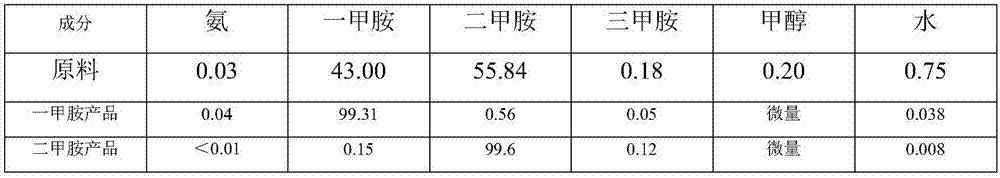

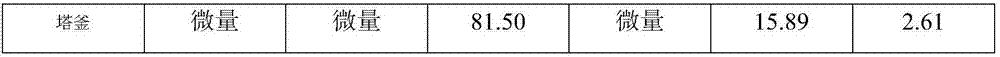

[0023] According to the method of the present invention, the mixed raw materials of monomethylamine and dimethylamine from the dehydration tower are separated, the separation main tower and the side line tower are all packed towers, the feed composition is shown in the data in the table below, and the feed temperature is 50°C. The feed rate is 18 tons / h, the top pressure of the separation main tower is 0.68MPa, the top temperature is 46.3°C, the bottom temperature is 82°C, the reflux ratio is 5.0, the top pressure of the side line tower is 0.66MPa, and the top temperature of the side line column is 62.8 DEG C, reflux ratio is 2.0, separated by rectifying tower, main tower top monomethylamine product and side line tower top dimethylamine product quality are also listed in the table below, the content of water in the side line product dimethylamine is 0.012%.

[0024] Element

Embodiment 2

[0026] According to the method of the present invention, the mixed raw materials of monomethylamine and dimethylamine from the dehydration tower are separated, the separation main tower and the side line tower are all packed towers, the feed composition is shown in the data in the table below, and the feed temperature is 50°C. The feed rate is 18 tons / h, the top pressure of the separation main tower is 0.7MPa, the top temperature is 47.0°C, the bottom temperature is 80°C, the reflux ratio is 7.0, the top pressure of the side line tower is 0.68MPa, and the top temperature is 63.5°C , the reflux ratio is 2.0, separated by the rectifying tower, the main tower top monomethylamine product and the side line tower top dimethylamine product quality are also listed in the table below, and the content of water in the side line product dimethylamine is 0.010%.

[0027] Element

Embodiment 3

[0029]According to the method of the present invention, the mixed raw materials of monomethylamine and dimethylamine from the dehydration tower are separated, the separation main tower and the side line tower are all packed towers, the feed composition is shown in the data in the table below, and the feed temperature is 50°C. The feed rate is 18 tons / h, the top pressure of the separation main tower is 0.60MPa, the top temperature is 41.5°C, the bottom temperature is 75°C, the reflux ratio is 4.0, the top pressure of the side line tower is 0.58MPa, and the top temperature is 58.0°C , the reflux ratio is 0.5, separated by the rectifying tower, the main tower top monomethylamine product and the side line tower top dimethylamine product quality are also listed in the table below, and the content of water in the side line product dimethylamine is 0.008%.

[0030]

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com