Visible light curable material for 3D printing, 3D printing apparatus, and product

A 3D printing and visible light technology, applied in the direction of additive processing, etc., can solve the problems of limited application range, safety and unsatisfactory production cost, etc., and achieve the effect of low viscosity, small shrinkage rate of solid products, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

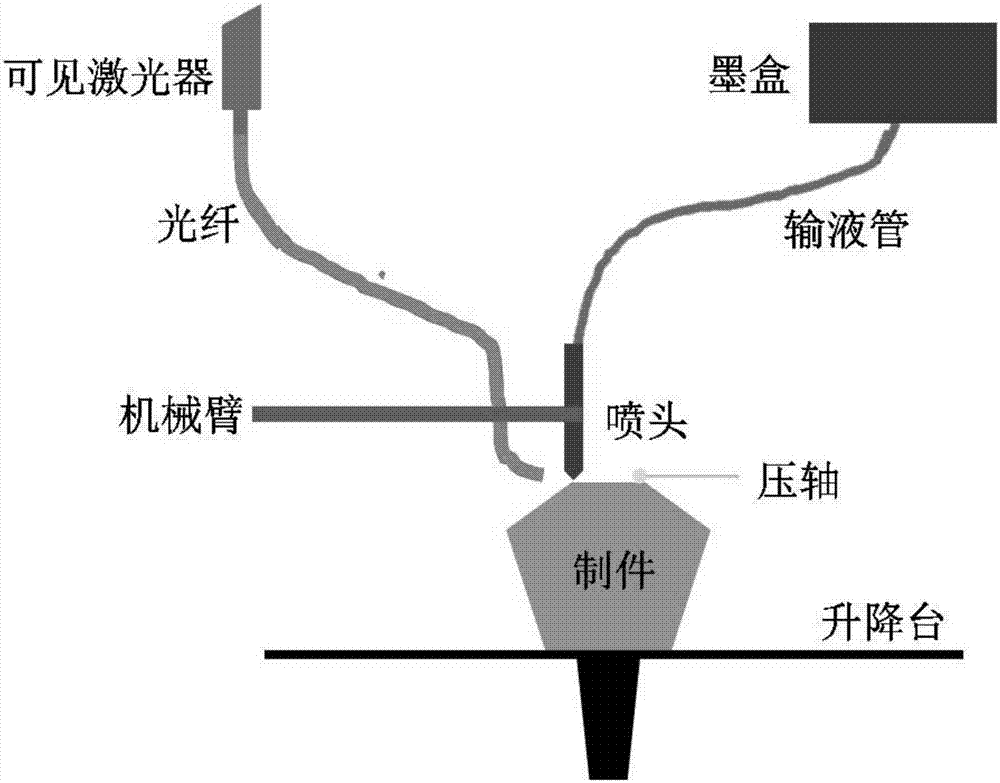

[0056] As mentioned above, the present invention provides a kind of article and its preparation method, with figure 2 The shown 3D printing device is an example, and the preparation method of the product includes the following steps:

[0057] 1) Stir and mix 100 parts by weight of polymerizable monomer, 0.01-5 parts by weight of photoinitiator, 0-5 parts by weight of photoinitiator auxiliary, and 1-20 parts by weight of other functional auxiliary agents in a normal temperature environment Homogeneous, to obtain a homogeneous mixture;

[0058] 2) The mixture obtained in step 1) is sent from the container to the nozzle through the infusion device of the above-mentioned 3D printing device, and the mixture ejected from the nozzle is cured under the irradiation of the laser or monochromatic visible light source.

[0059] Wherein, the step 2) specifically includes: sending the mixture obtained in step 1) into the nozzle through the infusion device of the above-mentioned 3D printin...

Embodiment 1

[0063] 1) With 30 parts by weight of bisphenol A epoxy acrylate (E-51), 70 parts by weight of methyl methacrylate (MMA), 0.1 parts by weight of camphorquinone (CQ), 0.1 parts by weight of triethyl Amine, 5 parts by weight of micron calcium carbonate powder, and 1 part by weight of lead chrome yellow are stirred and mixed uniformly in a normal temperature environment to obtain a homogeneous mixture;

[0064] 2) the mixture obtained in step 1) is passed through the figure 2The infusion device of the shown 3D printing device is sent into the nozzle, and the nozzle moves according to the preset trajectory under the control of the computer. Curing under the radiation of the light source, stacking layer by layer, forming, and making the article of the present invention.

[0065] The material used for 3D printing in this embodiment (that is, the homogeneous mixture) has low viscosity (about 220cps, normal temperature), fast curing speed (about 2 seconds for surface solidification t...

Embodiment 2

[0068] 1) the urethane acrylate of 70 parts by weight, the trimethylolpropane trimethacrylate (TMPTMA) of 30 parts by weight, the fluorinated diphenyl titanocene of 0.1 part by weight, the nano-carbon powder of 5 parts by weight, 1 part by weight of chrome red is stirred and mixed evenly in a normal temperature environment to obtain a homogeneous mixture;

[0069] 2) the mixture obtained in step 1) is passed through the figure 2 The infusion device of the 3D printing device shown is fed into the nozzle, and the nozzle moves according to the preset trajectory under the control of the computer, and at the same time, the nozzle continuously and constantly ejects the mixture, and the mixture is in the 470nm LED blue color of the 3D printing device of the present invention. Curing under the radiation of a laser light source, stacking layer by layer, and forming, the article of the invention is obtained.

[0070] The material used for 3D printing in this embodiment (that is, the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com