High-temperature pyrolysis gas reclamation system and method

A high-temperature pyrolysis and warm-heating technology, used in climate sustainability, acetylene generators, chemical industry, etc., can solve problems such as underutilization of sensible heat and chemical heat, and improve energy self-sufficiency, improve thermal efficiency, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

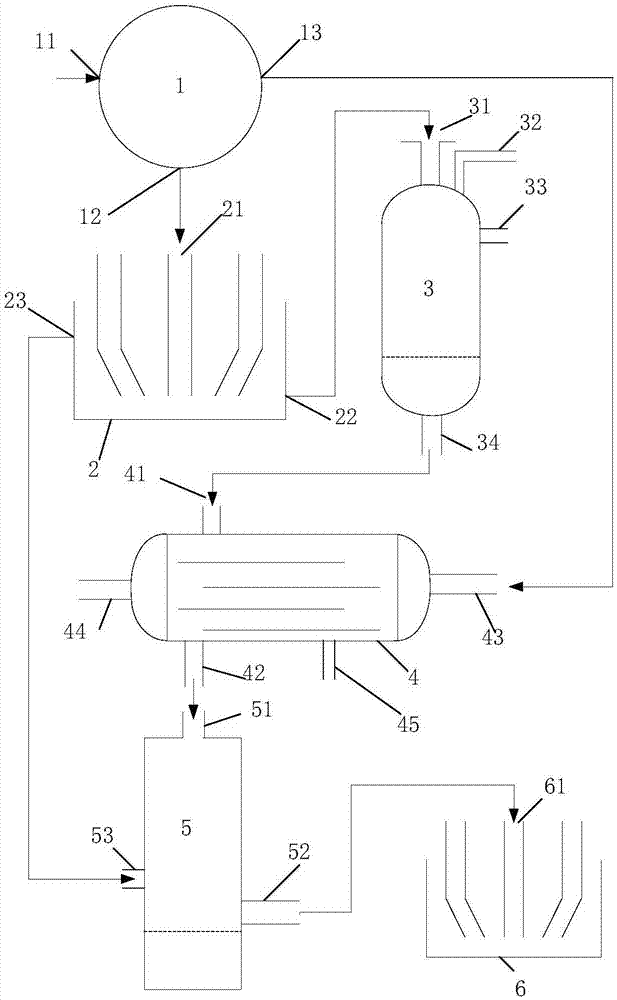

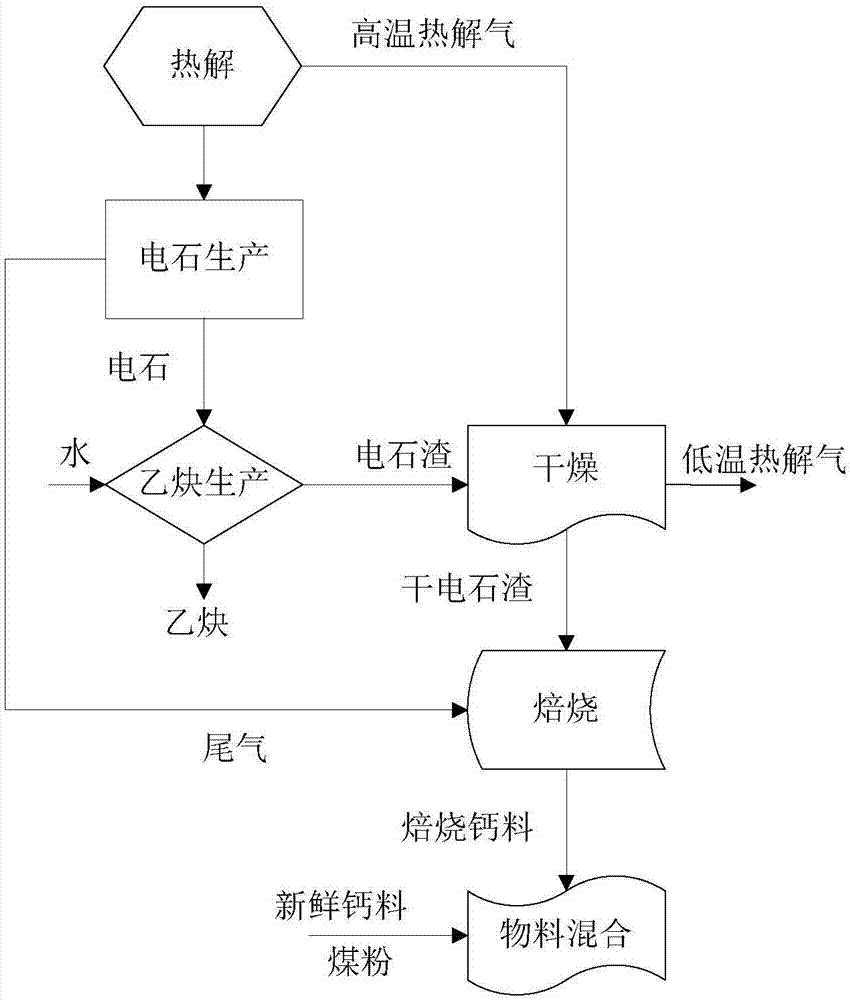

[0056] 1. The raw material is pyrolyzed in a pyrolysis furnace with a pyrolysis temperature of 900°C and a pyrolysis time of 1 hour to obtain solid products and high-temperature pyrolysis gas.

[0057] 2. Send the solid product into the calcium carbide furnace and heat it to 2250°C to generate calcium carbide and exhaust gas. The heating time is 40 minutes.

[0058] 3. The calcium carbide is sent to the acetylene generator to react with water to generate acetylene and calcium carbide slag.

[0059] 4. Send the carbide slag into the drying device, pass the high-temperature pyrolysis gas into the drying device, and dry the carbide slag to obtain dry carbide slag and low-temperature pyrolysis gas; adjust the intake of high-temperature pyrolysis gas in the drying device through the air flow valve The amount of high-temperature pyrolysis gas drying the carbide slag is controlled at 60 minutes to fully dry the carbide slag. The temperature of the dried carbide slag is 110°C, and the...

Embodiment 2

[0064] 1. The raw material is pyrolyzed in a pyrolysis furnace with a pyrolysis temperature of 600°C and a pyrolysis time of 1.5 hours to obtain solid products and high-temperature pyrolysis gas.

[0065] 2. Send the solid product into the calcium carbide furnace and heat it to 2200°C to generate calcium carbide and exhaust gas. The heating time is 45 minutes.

[0066] 3. The calcium carbide is sent to the acetylene generator to react with water to generate acetylene and calcium carbide slag.

[0067] 4. Send the carbide slag into the drying device, pass the high-temperature pyrolysis gas into the drying device, and dry the carbide slag to obtain dry carbide slag and low-temperature pyrolysis gas; adjust the intake of high-temperature pyrolysis gas in the drying device through the air flow valve The amount of high-temperature pyrolysis gas drying the carbide slag is controlled at 50 minutes to fully dry the carbide slag. The temperature of the dried carbide slag is 120°C, and ...

Embodiment 3

[0072] 1. The raw material is pyrolyzed in a pyrolysis furnace with a pyrolysis temperature of 500°C and a pyrolysis time of 2 hours to obtain solid products and high-temperature pyrolysis gas.

[0073] 2. Send the solid product into the calcium carbide furnace and heat it to 2100°C to generate calcium carbide and exhaust gas. The heating time is 50 minutes.

[0074] 3. The calcium carbide is sent to the acetylene generator to react with water to generate acetylene and calcium carbide slag.

[0075] 4. Send the carbide slag into the drying device, pass the high-temperature pyrolysis gas into the drying device, and dry the carbide slag to obtain dry carbide slag and low-temperature pyrolysis gas; adjust the intake of high-temperature pyrolysis gas in the drying device through the air flow valve The amount of high-temperature pyrolysis gas drying the carbide slag is controlled at 30 minutes to fully dry the carbide slag. The temperature of the dried carbide slag is 130°C, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com