Novel high-power millimeter-wave bipyramidal water load

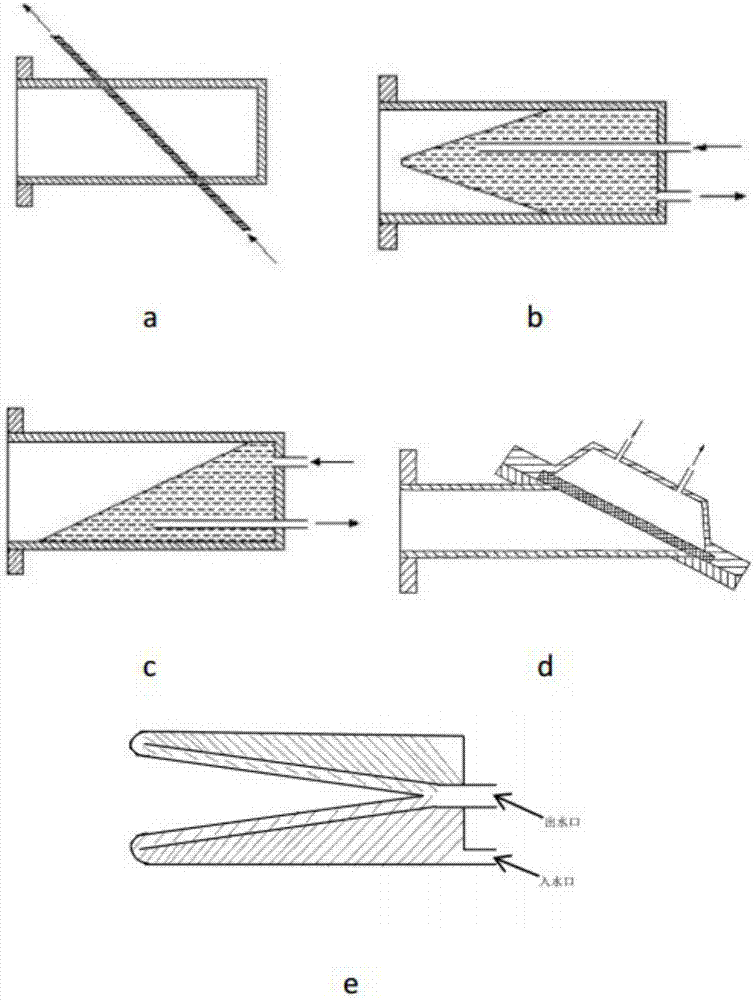

A double-cone, water-loaded technology, applied to waveguide devices, electrical components, circuits, etc., can solve the problems of slow water flow on the inner wall of the water chamber, high pressure in the water chamber, and glass breakage, etc., to reduce the volume of the water load, Improve the water velocity and reduce the effect of electromagnetic reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

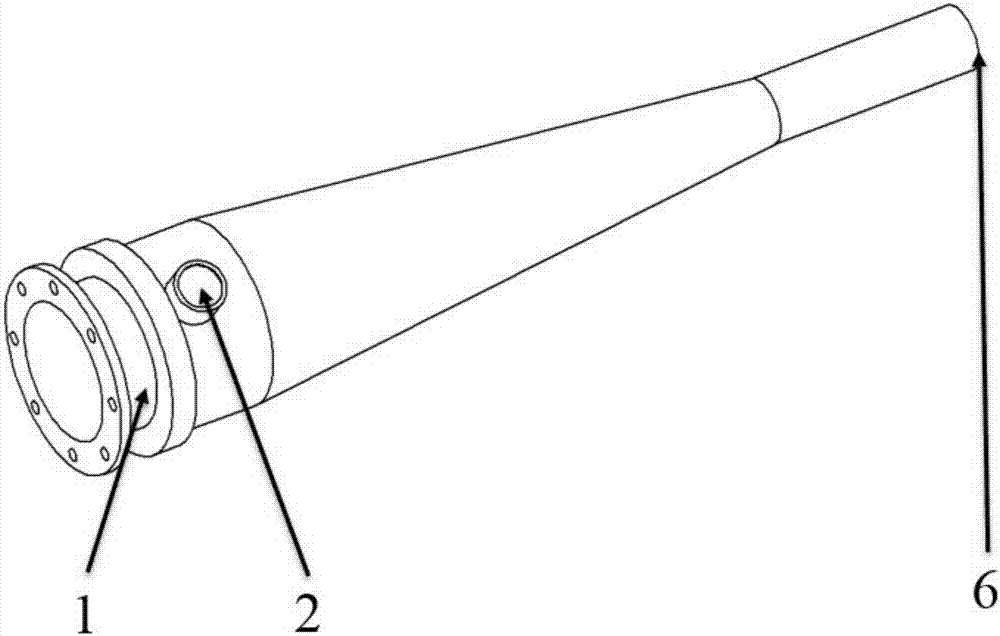

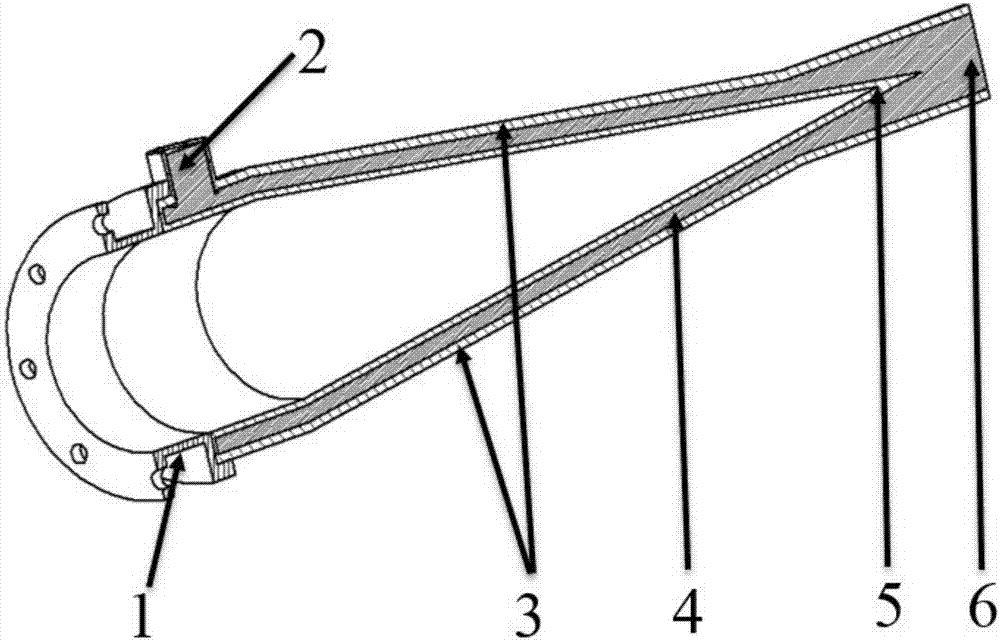

[0061] The following combines a working in Ku-band TE 11 The model water load design example and accompanying drawings further elaborate the present invention in detail.

[0062] Design method:

[0063] Firstly, with the help of geometrical optics analysis method and theoretical analysis, the analysis model of high-power water load is established, and the structural size of the water load is given. Then, the simulation model is established by using the electromagnetic simulation software HFSS, and the S-parameter analysis and electric field analysis of the water load are carried out. Finally, the fluid simulation is used. The software ANSYS Workbench performs water load fluid analysis and calculates the internal water flow velocity distribution of the water load.

[0064] Ku-band TE 11 Model water load design goals:

[0065] Working mode: TE 11 mold;

[0066] Working frequency band: Ku band (12——18GHz);

[0067] Reflection parameters: less than -30dB;

[0068] External ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com