A high osmotic pressure online reverse cleaning method and device for nanofiltration and reverse osmosis membranes

A reverse cleaning and reverse osmosis membrane technology, applied in osmosis/dialysis water/sewage treatment, reverse osmosis, semi-permeable membrane separation, etc., can solve the problems of frequent, pollution, secondary pollution cleaning, etc. Aging and damage, the effect of saving drug costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

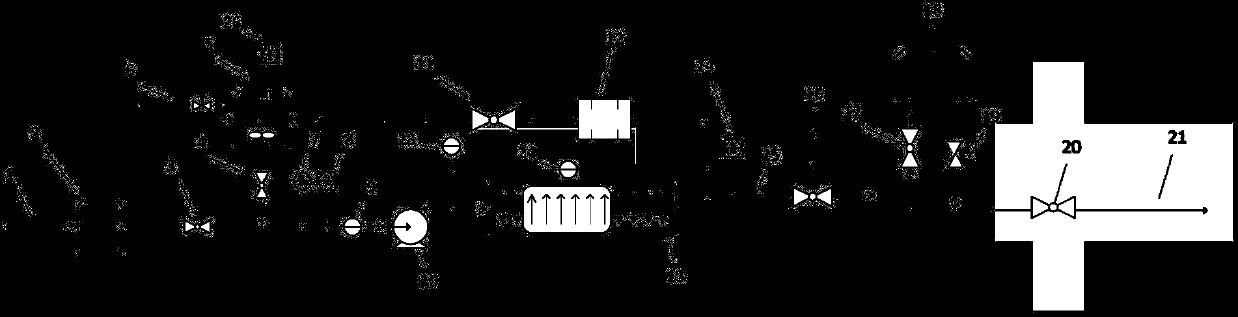

[0046] Such as figure 1 As shown, the present invention also provides a high osmotic pressure online reverse cleaning device for nanofiltration and reverse osmosis membranes, comprising:

[0047] The concentrated brine storage system includes a concentrated brine tank 5, the water inlet of the concentrated brine tank 5 is connected to the concentrated brine outlet pipe 15 of the nanofiltration and reverse osmosis membrane pressure vessel 13 and a concentrated brine decompression orifice 12 and The water inlet valve 11 of the concentrated brine tank, the water outlet of the concentrated brine tank 5 is connected before the pressure gauge 7, the conductivity sensor 3 8, the inflow flow meter 9 and the reverse osmosis high-pressure water inlet pump 10, and a concentrated brine tank is arranged on the connecting pipeline Outlet valve 4;

[0048] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com