Modification method of hexagonal boron nitride and hydroxy modified boron nitride

A hexagonal boron nitride and hydroxyl modification technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of h-BN surface defect density and types are limited, difficult to control, etc., to achieve simple and efficient surface Effects of modification, easy operation, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation of embodiment 1 hydroxyl modified boron nitride (HO-BN)

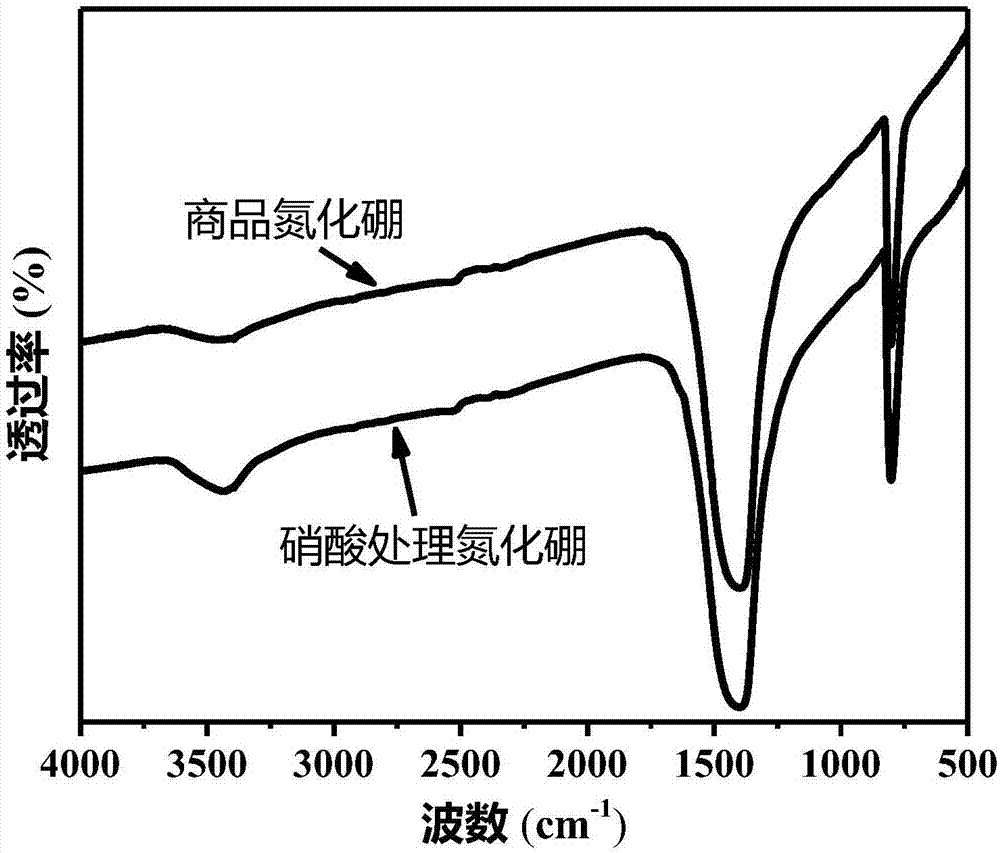

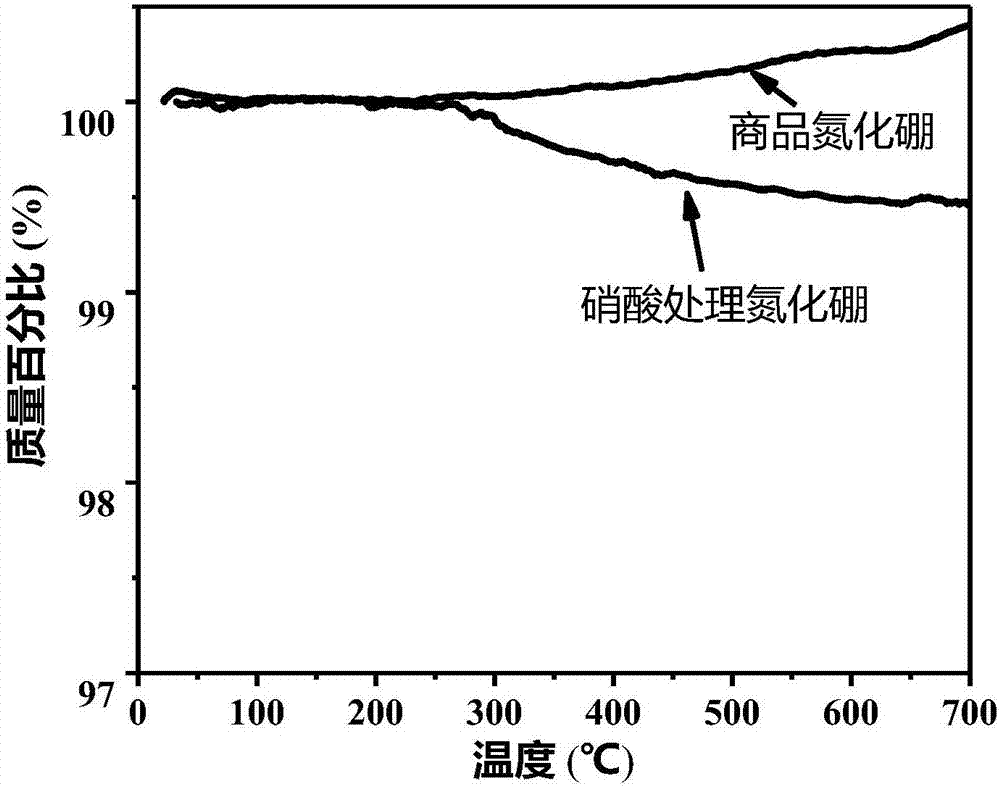

[0047] 1) Pretreatment of commodity h-BN powder

[0048] Weigh 2g of commercial h-BN powder into a 250mL round bottom flask, add 80mL of 10% nitric acid solution (65% nitric acid: water = 1:5.5 (v / v)) to it, and put a stirring magnet. Place the round-bottomed flask in an oil bath, start magnetic stirring, heat to 80°C, keep it for 5 hours, and then cool it down to room temperature naturally to obtain a dispersion. Place the dispersion in a high-speed centrifuge (HC-2518), centrifuge the BN particles at a speed of 8000rpm, and rinse with deionized water until the washing liquid is neutral, and the treated product is dried at 50°C with electric blast Dry in the box (GZX-9070MBE) for 24h. FT-IR spectra of BN powder before and after pretreatment as figure 1 as shown, figure 1 is the infrared spectrum of h-BN before and after nitric acid treatment, by figure 1 It can be seen that there is basicall...

Embodiment 2

[0051] The preparation of embodiment 2 hydroxyl modified boron nitride (HO-BN)

[0052] 1) The pretreatment of h-BN powder is the same as in Example 1.

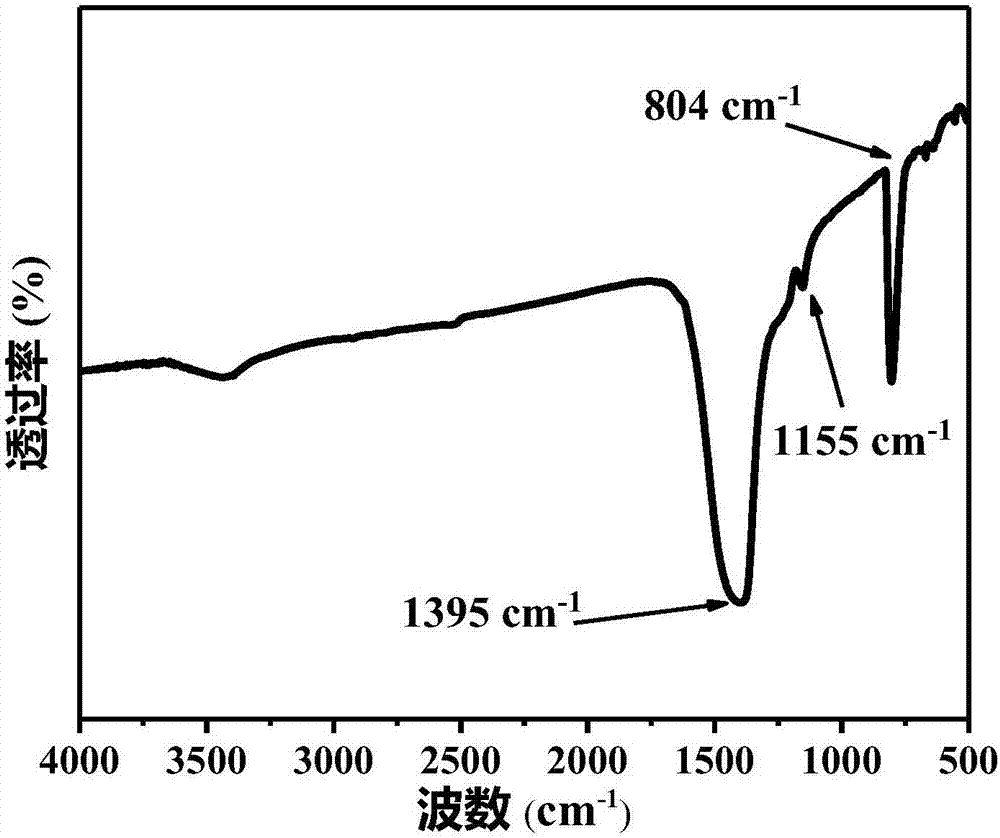

[0053] 2) Preparation of HO-BN

[0054] Weigh 100 mg of h-BN powder treated with nitric acid into a 100 mL round bottom flask, add 50 mL of deionized water, and place it in an ultrasonic disperser to make the powder ultrasonically dispersed. Then 20 μL of formic acid and 1.1 mL of concentrated sulfuric acid were added in turn, and placed in a stirring magnet. The round bottom flask was placed in the cobalt source chamber with an iron stand, magnetic stirring was started, and the radiation was irradiated for 48 hours. The absorbed dose rate was 105.4Gy / min (calibrated with a ferrous sulfate dosimeter), and the total absorbed dose was 303.4kGy. After the irradiation, the round bottom flask was taken out, and after standing for a period of time, the particles were deposited. The upper liquid was poured out, and the precipitat...

Embodiment 3

[0055] The preparation of embodiment 3 epoxy group modified boron nitride (EP-BN)

[0056] 1) The pretreatment of h-BN powder is the same as in Example 1.

[0057] 2) Preparation of HO-BN

[0058] Weigh 100 mg of h-BN powder treated with nitric acid into a 100 mL round bottom flask, add 50 mL of deionized water, and place it in an ultrasonic disperser to make the powder ultrasonically dispersed. Then 20 μL of formic acid and 1.1 mL of concentrated sulfuric acid were added in turn, and placed in a stirring magnet. The round-bottomed flask was fixed in the cobalt source chamber with an iron stand, magnetic stirring was started, and it was irradiated for 18 hours. The absorbed dose rate was 101.3Gy / min (calibrated by ferrous sulfate dosimeter), and the total absorbed dose was 109kGy. After the irradiation, the round bottom flask was taken out, and after standing for a period of time, the particles were deposited. The upper liquid was poured out, and the precipitate was rinsed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com