Carbon/magnesium aluminum spinel composite powder

A magnesia-aluminum spinel and composite powder technology, applied in the field of inorganic composite materials, can solve the problems of difficult carbon dispersion, high cost, limitation and the like, and achieve the effects of improving the carbon dispersion problem, reducing the production cost and making the preparation process simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The carbon / magnesium aluminum spinel composite powder prepared by the present invention not only has the advantages of carbon and magnesium aluminum spinel in resisting slag erosion, but more importantly, it solves the problem of carbon dispersion and can endow refractory materials with superior erosion resistance performance.

[0027] In the carbon / magnesium aluminum spinel composite powder prepared by the present invention, the particle size of carbon is reduced and the specific surface area is increased, so that the application of the composite powder can improve the corrosion resistance and heat resistance of the carbon-containing refractory while reducing the carbon content. shock resistance; refractory materials containing magnesium-aluminum spinel have good corrosion resistance, which is attributed to the fact that magnesium-aluminum spinel can absorb steel slag low-melting point oxides to form a solid solution without forming low-melting point oxides, and can cha...

Embodiment 1

[0029] This embodiment provides a preparation method of carbon / magnesium aluminum spinel composite powder, the raw materials include: magnesium oxalate (purity ≥ 99.0%), magnesium peroxide composite powder (content ≥ 30.0%, the rest is magnesium oxide), aluminum powder (purity ≥ 99.0%) and aluminum oxide (purity ≥ 99.0%) are raw materials, by mass percentage, magnesium oxalate is 33.4%, magnesium peroxide is 22.2%, aluminum oxide is 22.2%, aluminum powder is 22.2%;

[0030] It includes the following steps: put the above-mentioned uniformly mixed raw materials into a mold, and then dry press them to form a cylindrical sample with a diameter of 20mm and a height of 30mm; after the molding is completed, the sample is demoulded, and then Put it into a self-propagating high-temperature reaction furnace, place a C-Ti igniter on the sample, and the self-propagating high-temperature synthesis reaction is initiated by the heat generated by the C-Ti reaction placed on the top of the samp...

Embodiment 2

[0033] This example provides a method for preparing carbon / magnesium aluminum spinel composite powder. The difference from Example 1 is that, by mass percentage, magnesium oxalate is 28.6%, magnesium peroxide is 28.6%, and aluminum oxide is 19.0%. , aluminum powder is 23.8%;

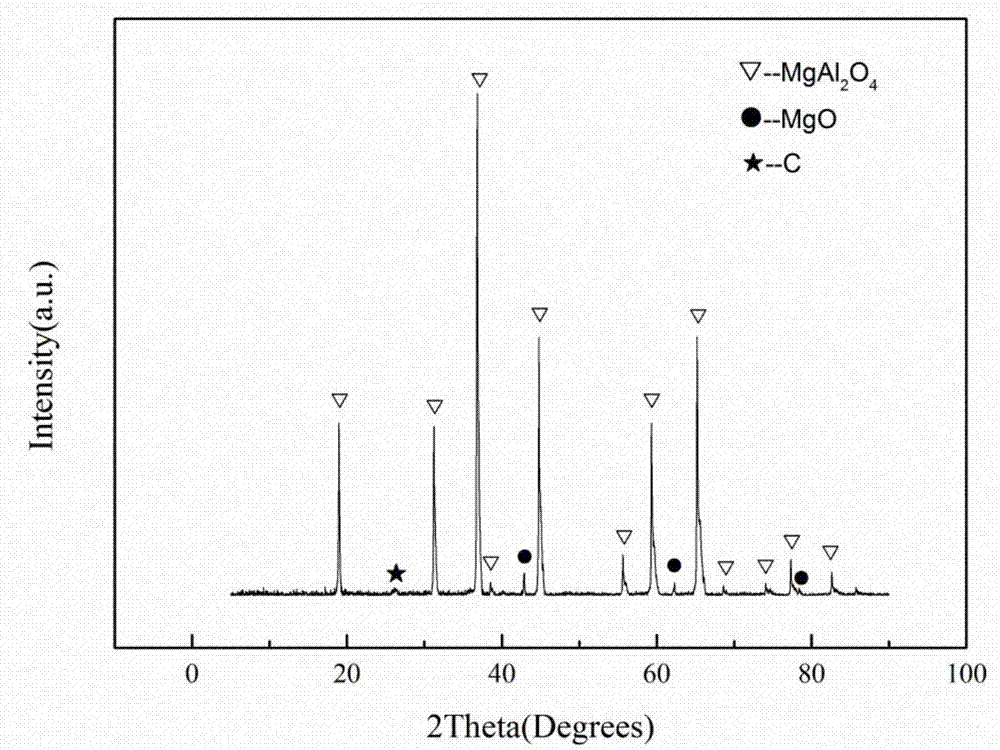

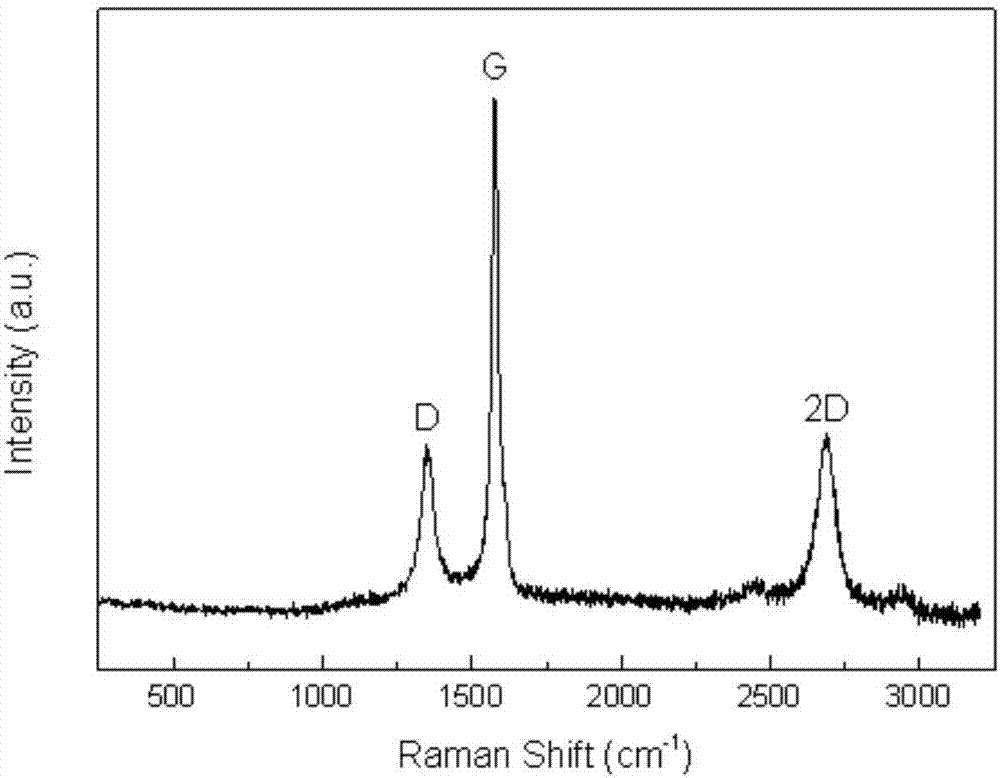

[0034] Carry out X-ray diffraction analysis to the prepared carbon / magnesium-aluminum spinel composite powder, obtain XRD pattern see Figure 4 ,Depend on Figure 4 It can be seen that the main components of the composite powder include carbon, magnesium aluminum spinel and magnesium oxide. The carbon / magnesium aluminum spinel composite powder prepared in embodiment 2 has been carried out Raman spectroscopic analysis, and the Raman spectrogram that obtains sees Figure 5 ,Depend on Figure 5 It can be seen that the prepared carbon / magnesium aluminum spinel composite powder contains carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com