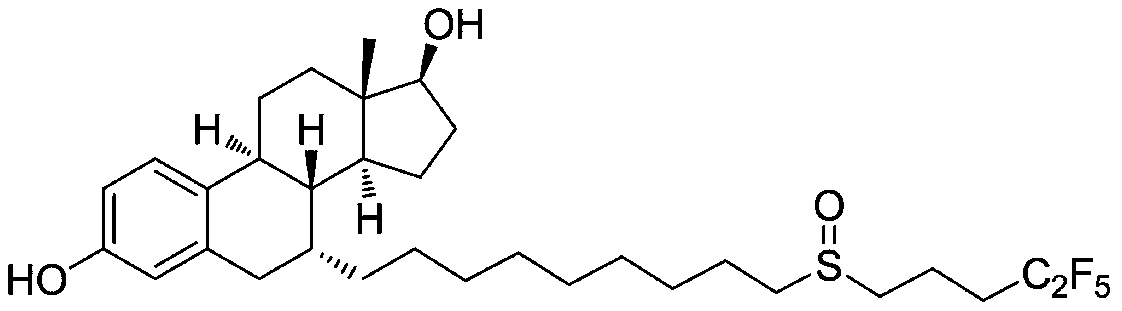

Synthetic method of fulvestrant intermediate

A technology of fulvestrant and a synthesis method, which is applied in the synthesis field of estratane-triene-diol compounds, can solve the problems of large influence, complicated post-processing, etc., so as to simplify the production process and improve the product yield and quality, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022]

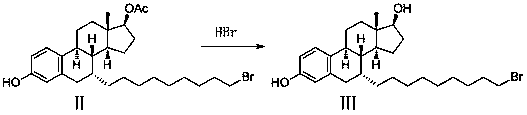

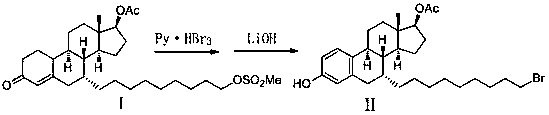

[0023] Add 10.7g of the compound of formula I with a purity of 98.4% to the reaction flask, add 200ml of acetonitrile, 7.0g of pyridinium bromide perhydrogen perbromide, and stir for 1 hour at 20-25°C. After the reaction is complete, add 60ml of 1mol / L lithium hydroxide aqueous solution, heat at 50-60°C for 2 hours, cool down, filter out the precipitate, concentrate the filtrate under reduced pressure to obtain an oil, add 200ml of ethyl acetate, 50ml of saturated saline, stir and separate , the organic phase was dried over anhydrous sodium sulfate, and concentrated under reduced pressure to obtain 10.1 g of the compound of formula II with a purity of 98.5%.

Embodiment 2

[0025]

[0026] Add 10.7g of the compound of formula I with a purity of 98.4% to the reaction flask, add 200ml of acetonitrile, 7.7g of pyridinium bromide perhydrogen perbromide, and stir at 20-25°C for 1 hour. After the reaction is complete, add 60ml of 1mol / L lithium hydroxide aqueous solution, heat at 50-60°C for 2 hours, cool down, filter out the precipitate, concentrate the filtrate under reduced pressure to obtain an oil, add 200ml of ethyl acetate, 50ml of saturated saline, stir and separate , the organic phase was dried over anhydrous sodium sulfate, and concentrated under reduced pressure to obtain 9.8 g of the compound of formula II with a purity of 98.4%.

Embodiment 3

[0028]

[0029] Add 10.7g of the compound of formula I with a purity of 98.4% to the reaction flask, add 200ml of acetonitrile, 7.7g of pyridinium bromide perhydrogen perbromide, and stir for 2 hours at 0-15°C. After the reaction is complete, add 60ml of 1mol / L lithium hydroxide aqueous solution, heat at 50-60°C for 2 hours, cool down, filter out the precipitate, concentrate the filtrate under reduced pressure to obtain an oil, add 200ml of ethyl acetate, 50ml of saturated saline, stir and separate , the organic phase was dried over anhydrous sodium sulfate, and concentrated under reduced pressure to obtain 9.9 g of the compound of formula II with a purity of 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com