Polylactic acid hybrid biological membrane as well as preparation method and application thereof

A technology of polylactic acid and biofilm, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems that limit the wide application of polylactic acid biofilm, poor body adhesion, and difficult fixation, so as to prevent clinical prevention of tissue adhesion, High porosity, good oral isolation and anti-adhesion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

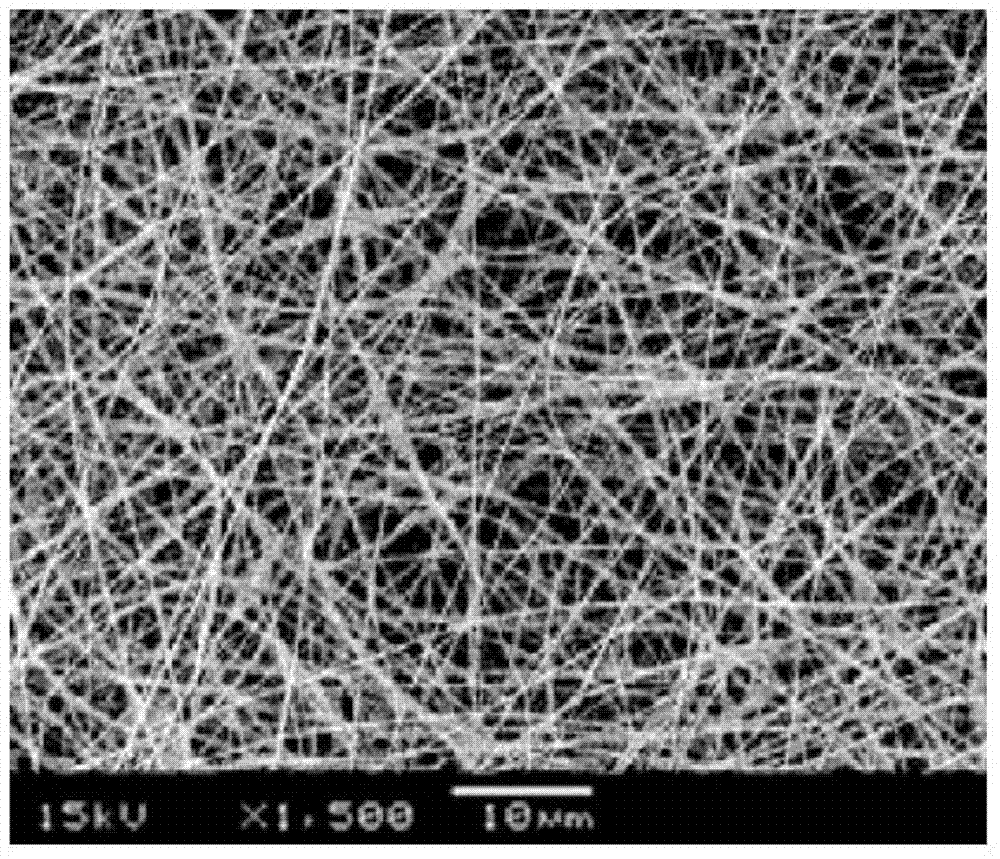

[0028] A polylactic acid composite biofilm, wherein the mass ratio of polylactic acid and collagen is 5:1; prepared by electrospinning, the thickness of the polylactic acid composite biofilm is 0.05mm, the thickness accuracy is controlled at ±0.02mm, and the specific surface area is 0.001m 2 / g, there are micropores with a maximum pore diameter of ≤10μm, and a tensile strength of ≥3MPa.

Embodiment 2

[0030] A polylactic acid composite biofilm, wherein the mass ratio of polylactic acid and collagen is 8:1; prepared by electrospinning, the thickness of the polylactic acid composite biofilm is 0.1mm, the thickness accuracy is controlled at ±0.02mm, and the specific surface area is 0.01m 2 / g, there are micropores with a maximum pore diameter of ≤10μm, and a tensile strength of ≥3MPa.

Embodiment 3

[0032] A polylactic acid composite biofilm, wherein the mass ratio of polylactic acid and collagen is 3:2; polylactic acid is racemic polylactic acid, the intrinsic viscosity [η] is 100mL / g, and the weight average molecular weight Mw is 300000; molecular weight distribution 2.0; prepared by freeze-drying method, the thickness of polylactic acid composite biofilm is 0.2mm, the thickness accuracy is controlled at ±0.02mm, and the specific surface area is 0.005m 2 / g, there are micropores with a maximum pore size of ≤10μm, and a tensile strength of ≥3MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com