Battery box and manufacture method thereof

A manufacturing method and box body technology, applied in the direction of battery box/case material, battery pack parts, battery box/coating, etc., can solve problems such as difficult recycling, low mechanical properties, hidden safety hazards, etc., to reduce environmental pressure , high modulus, and high manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

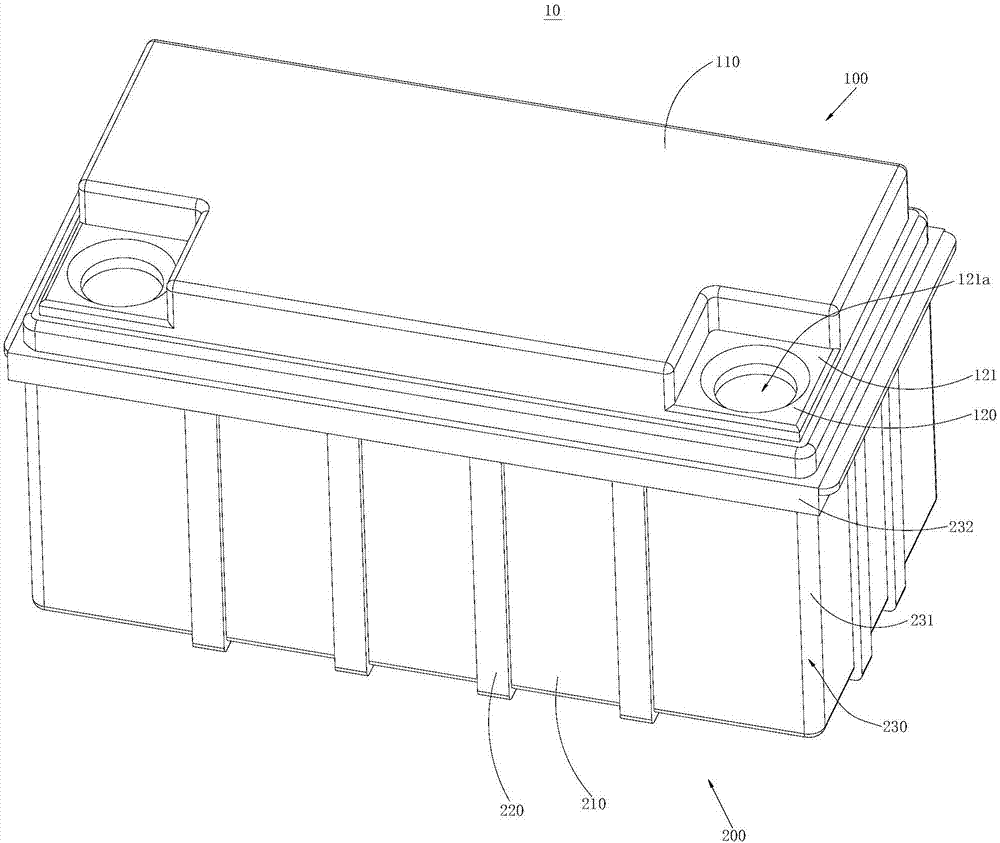

[0060] The continuous fiber-reinforced thermoplastic resin matrix composite material is made of continuous glass fiber-reinforced PP prepreg sheet, and the fiber volume content is 50%. The discontinuous fiber reinforced thermoplastic resin is made of long glass fiber reinforced PP, and the fiber weight content is 40%.

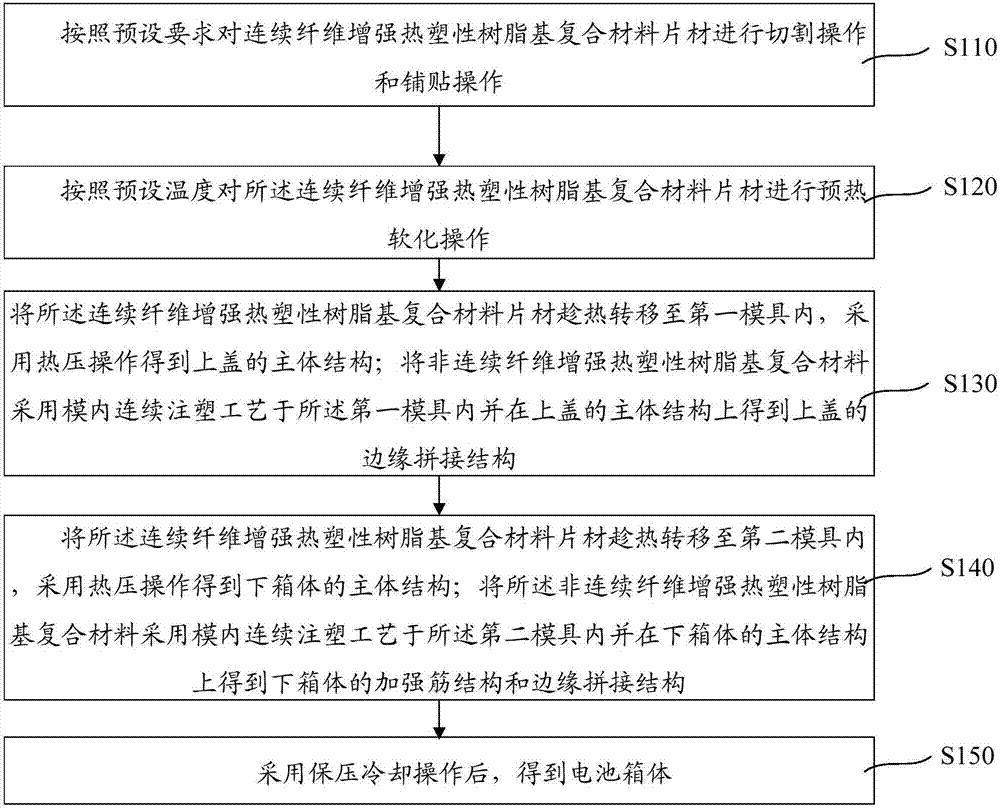

[0061] The continuous glass fiber reinforced PP sheet is cut according to the designed shape by a laser cutting machine, and then paved and assembled. The thickness of the designed main structure is 2.5mm. Use an infrared heating device to preheat the assembled sheet to 160°C, the preheating time is 45s, quickly transfer the preheated sheet to a molding mold with a mold temperature of 150°C, and press the mold to form the main body of the battery box structure. Then use long glass fiber reinforced PP resin to injection mold the battery box assembly and rib structure, and the injection molding temperature is 245°C. After holding the pressure and cooling, the m...

Embodiment 2

[0063]Continuous fiber-reinforced thermoplastic resin-based composites are made of unidirectional carbon fiber-reinforced PA66 prepreg sheet and unidirectional glass fiber-reinforced PA66 prepreg sheet, both of which have a fiber volume content of 55%. Long glass fiber reinforced PA66 is selected as the discontinuous fiber reinforced thermoplastic resin, and the fiber weight content is 45%.

[0064] Use high-speed robot cutting equipment to cut unidirectional prepreg sheets according to the design requirements, and carry out paving and assembly. The inner surface of the box is made of glass fiber reinforced PA66 prepreg sheets, and the rest of the layers are made of carbon fiber reinforced PA66 prepreg sheets. , the thickness of the main structure of the designed battery box is 2.0mm. Electromagnetic heating is used to preheat the assembled thermoplastic sheet to 270°C, and the preheating time is 50s. The preheated sheet is quickly transferred to a molding mold with a mold tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com