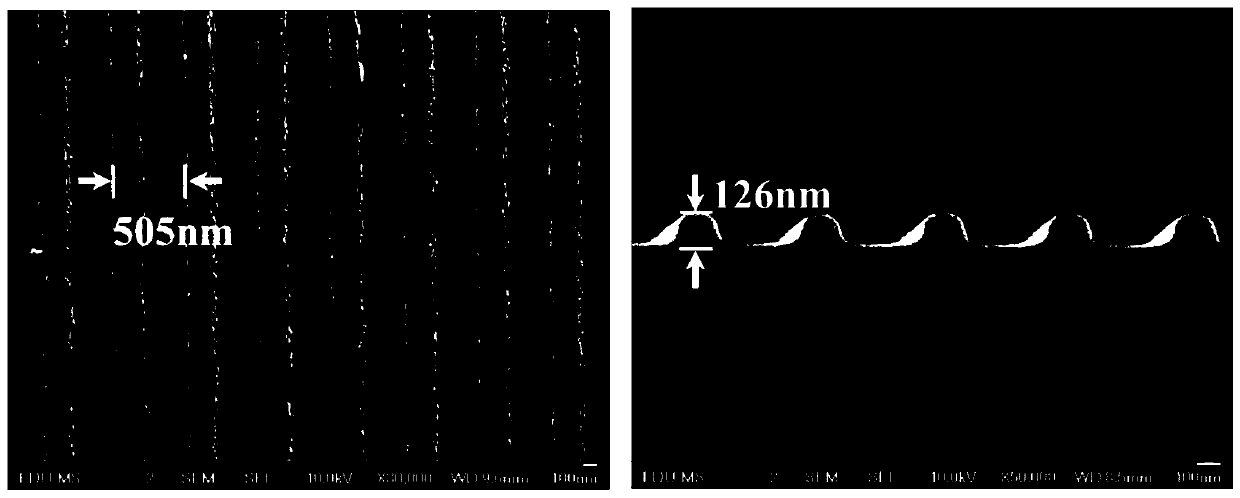

All-Silicon Distributed Feedback Laser

A distributed feedback, laser technology, applied in the laser field, can solve the problems of incompatibility, complex production process, high production cost, etc., and achieve the effect of avoiding incompatibility, compact structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following examples are used to illustrate the present invention, but not to limit the present invention.

[0046] 1. Raw material and formula:

[0047] Substrate: polished on both sides, volume is 20×20×0.2mm 3 High temperature resistant quartz substrate;

[0048] Template self-assembly anti-sticking layer: 1H, 1H, 2H, 2H-Perfluorooctyltrichlorosilane, Microresist technology company;

[0049] Template adhesion layer: OrmoPrime, Micro resist technology company;

[0050] Template raster layer: OrmoStamp, Micro resist technology company;

[0051] Buff materials: Dow Corning FOx-1x and FOx-2x Flowable Oxides, Dow Corning Corporation;

[0052] Substrate cleaning solution: alcohol (analytical grade), acetone (analytical grade), Sinopharm Chemical Reagent Co., Ltd.;

[0053] 2. Process parameter setting:

[0054] Preparation conditions: room temperature, clean environment;

[0055] Annealing temperature: 1100°C;

[0056] Annealing time: 60 minutes;

[0057] Subseq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com