Method for determining ferric oxide in silica

A ferric oxide and determination method technology, which is applied in the direction of chemical analysis by titration method, can solve the problems of low efficiency, difficult detection and inaccuracy of the detection method, and achieve the advantages of easy and quick grasp, obvious end point and accurate measurement results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

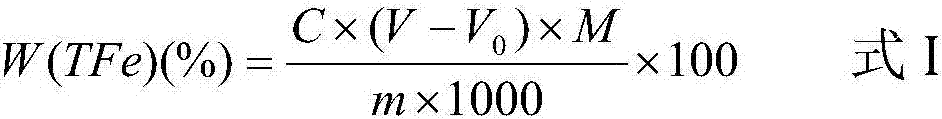

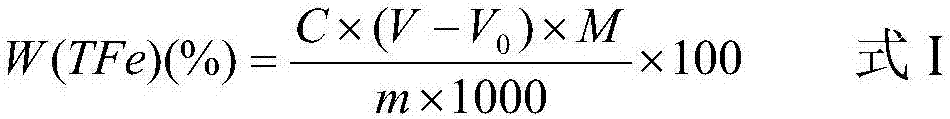

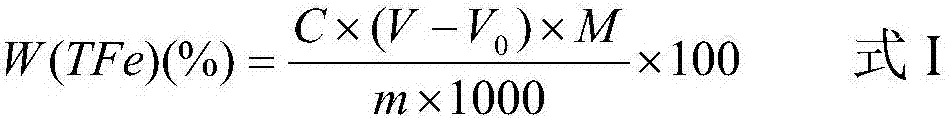

[0040] 【1. Method Summary】

[0041] Weigh the sample, dissolve it with sulfuric acid-phosphoric acid mixed acid, reduce a large amount of ferric iron with tin dichloride in hydrochloric acid medium, use sodium tungstate as indicator, add titanium trichloride dropwise to reduce the remaining ferric iron to Divalent, excess titanium trichloride is oxidized with potassium dichromate. Titrate with potassium dichromate using sodium diphenylamine sulfonate as indicator.

[0042] 【2. Sample size】

[0043] Weigh 0.5000g of the sample.

[0044] 【3. Analysis steps】

[0045] 3.1 Reagents

[0046] 1 hydrochloric acid (ρ1.19) (hydrochloric acid and water mixed at 1:1)

[0047] 2 sulfuric acid-phosphoric acid mixed acid (mixture of sulfuric acid and phosphoric acid at 5:3)

[0048] 3 sulfuric acid (mixture of sulfuric acid and water at 5:95)

[0049] 4 Titanium trichloride solution

[0050] Take a portion of titanium trichloride solution (15% to 20%), put it into a brown bottle and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com