A kind of method of making rare earth barium copper oxide superconducting film

A technology of rare earth barium copper oxide and superconducting film, which is applied in the usage of superconducting elements, equipment for manufacturing conductive/semiconducting layers, superconducting devices, etc., and can solve problems such as control factors that do not consider temperature and film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

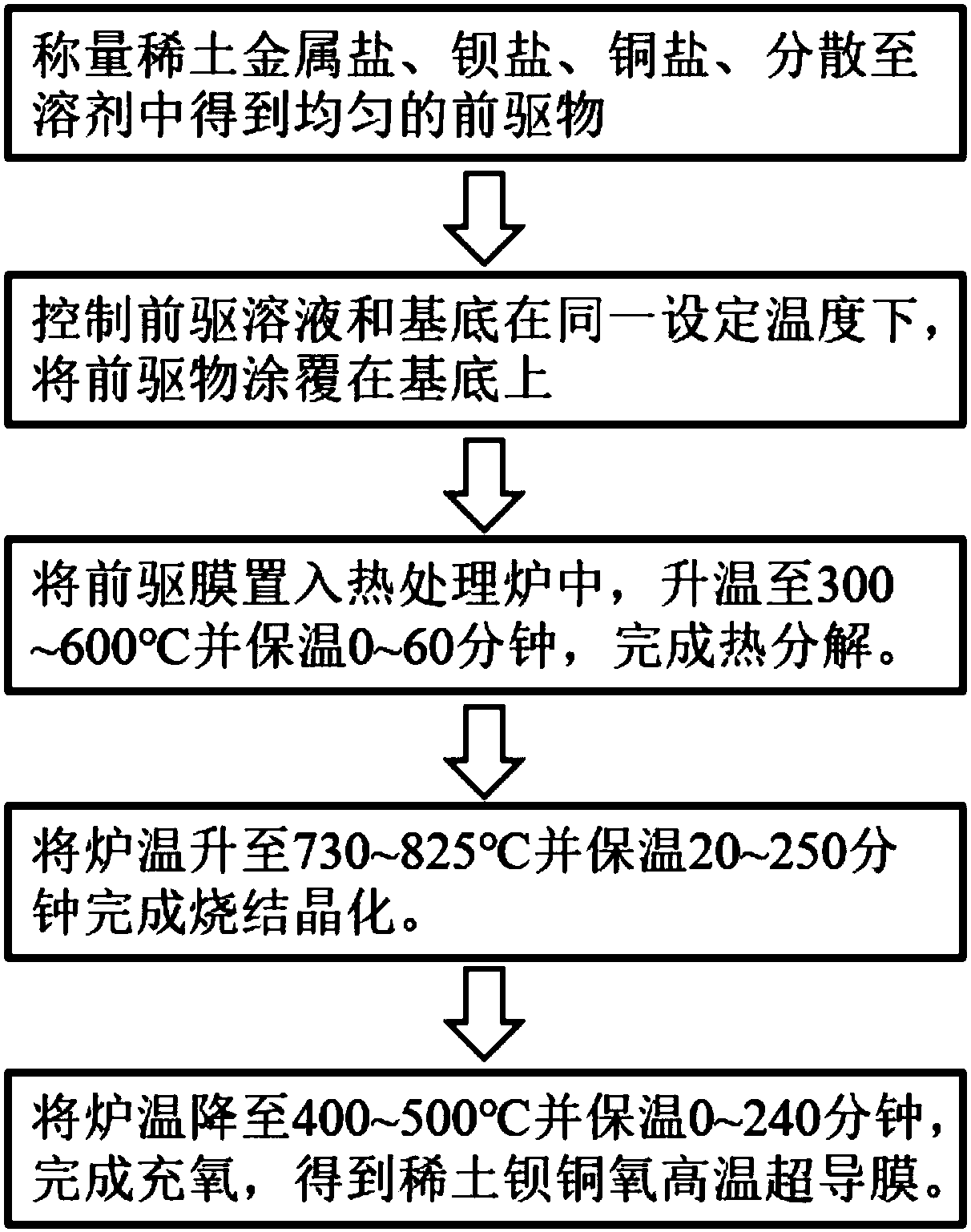

[0064] The preparation process is as figure 1 As shown, first, according to the metal cation molar ratio of 1: (1+x): 3 (where 0.5≤x≤1), yttrium acetate tetrahydrate, barium acetate, and copper acetate monohydrate were dissolved in deionized water, and trifluoroacetic acid was added thereto. After 2 times of rotary evaporation, the above-mentioned metal salt was finally dissolved in methanol to obtain a clear, transparent, dark blue precursor with a concentration of 1.5 mol / L.

[0065] Using an improved water bath, dip-coating was performed at temperatures of 0°C, 10°C, 20°C and 30°C, respectively, and the above precursor solution was coated on LaAlO 3 (lanthanum aluminate) single crystal substrate, and then placed in a tube furnace for rapid heat treatment, the YBCO precursor film can be obtained. The film section thickness was observed with a Hitachi Su8010 scanning electron microscope, and 5 values were taken for each sample to eliminate errors. Dip-coating at differen...

example 2

[0068] According to a method of preparing a solution according to the embodiment, a precursor with a concentration of 1.8mol / L is prepared, and then the precursor is added with a mass fraction of 25% polyethylene glycol 2000 (PEG2000), and the modification is obtained after fully stirring, dissolving and standing. precursors. By improving the temperature control of the water bath, dip-coating was carried out at temperatures of 0°C, 10°C, 20°C and 30°C, respectively, and the above precursor solution was applied to LaAlO by dip-coating technology. 3 (lanthanum aluminate) single crystal substrate, and then placed in a tube furnace for rapid heat treatment, the YBCO precursor film can be obtained. The film section thickness was observed with a Hitachi Su8010 scanning electron microscope, and 5 values were taken for each sample to eliminate errors. Dip-coating at different constant temperatures of 0°C, 10°C, 20°C, and 30°C, the thickness of the film is divided into 548nm, 493nm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com