Preparation of bifunctional catalyst diatomite domain limited cobalt-platinum-based composite material, and application of bifunctional catalyst diatomite domain limited cobalt-platinum-based composite material in electrocatalytic oxygen reduction reaction and oxygen evolution reaction

A technology of bifunctional catalysts and composite materials, applied in the field of preparation of nano-catalysts, can solve problems such as unpublished literature or patent reports, and achieve the effects of avoiding pollution and energy consumption, large catalytic activity, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Disperse diatomaceous earth to 40mL 3mol L -1 HCl solution, magnetically stirred for 12 hours, then suction filtered, washed with deionized water until the pH of the filtrate was ~7, and the filter cake was dried in a vacuum oven at 50°C for 12 hours, and the product was marked as DTM for future use.

[0037] (2) Control the molar ratio of Co and Pt to be Co / Pt=1 with the precursor salt of Co and Pt 0.25mmol CoCl 2 ·6H 2 O and 0.25mol H 2 PtCl 6 ·6H 2 O, add to 20mL EG solution, add 76mg DTM after the precursor salt is completely dissolved, stir for 30min, then start heating from room temperature to 160°C for 6h.

[0038] (3) When the reaction temperature drops to 40°C, add 76 mg of carbon powder, stir for 4 hours, and wash by centrifugation. CoPt-1 / DTM-C catalyst can be obtained by drying at 50℃ for 12h under vacuum condition.

[0039] Electrochemical performance test:

[0040] The electrochemical test and characterization was performed on the CHI 750E electro...

Embodiment 2

[0051] (1) Disperse diatomaceous earth to 40mL 3mol L -1 HCl solution, magnetically stirred for 12 hours, then suction filtered, washed with deionized water until the pH of the filtrate was ~7, and the filter cake was dried in a vacuum oven at 50°C for 12 hours, and the product was marked as DTM for future use.

[0052] (2) Control the molar ratio of Co and Pt to be Co / Pt=3 with the precursor salt of Co and Pt 0.75mmol CoCl 2 ·6H 2 O and 0.25mol H 2 PtCl 6 ·6H 2 O, add to 20mL EG solution, add 76mg DTM after the precursor salt is completely dissolved, stir for 30min, then start heating from room temperature to 160°C for 6h.

[0053] (3) When the reaction temperature dropped to 40°C, 76 mg of carbon powder was added, stirred for 4 hours, and washed by centrifugation. CoPt-3 / DTM-C catalyst can be obtained by drying at 50℃ for 12h under vacuum condition.

Embodiment 3

[0055] (1) Disperse diatomaceous earth to 40mL 3mol L -1 HCl solution, magnetically stirred for 12 hours, then suction filtered, washed with deionized water until the pH of the filtrate was ~7, and the filter cake was dried in a vacuum oven at 50°C for 12 hours, and the product was marked as DTM for future use.

[0056] (2) Control the molar ratio of Co and Pt to be Co / Pt=9 with the precursor salt of Co and Pt 2.25mmol CoCl 2 ·6H 2 O and 0.25mol H 2 PtCl 6 ·6H 2 O, add to 20mL EG solution, add 76mg DTM after the precursor salt is completely dissolved, stir for 30min, then start heating from room temperature to 160°C for 6h.

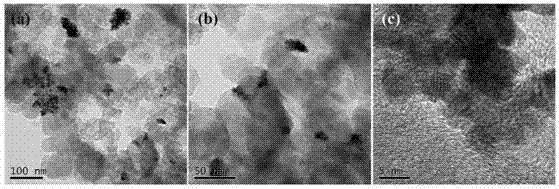

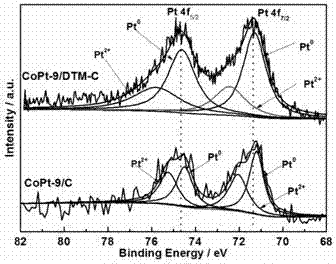

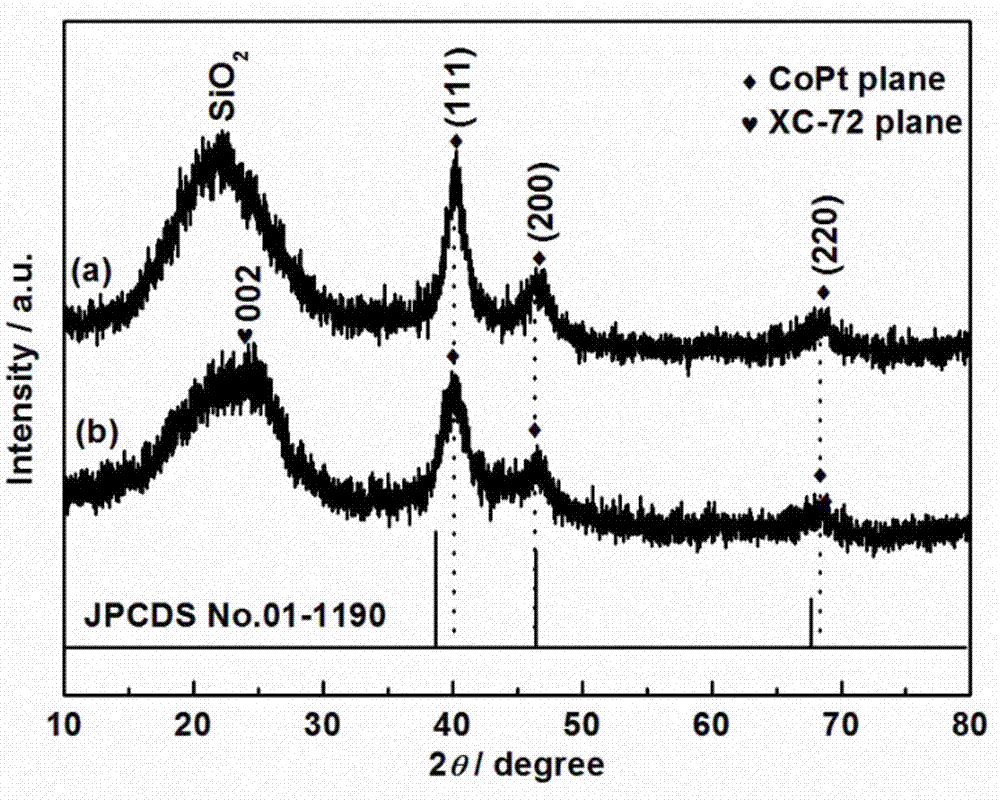

[0057] (3) When the reaction temperature dropped to 40°C, 76 mg of carbon powder was added, stirred for 4 hours, and washed by centrifugation. CoPt-9 / DTM-C catalyst can be obtained by drying at 50℃ for 12h under vacuum condition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com