Method for preparing fertilizer by acid treatment on agriculture wastes under high temperature and high pressure

An agricultural waste, high temperature and high pressure technology, applied in the field of agricultural waste resource recycling, can solve the problems of low utilization rate, limited economic benefit, and small environmental improvement effect, and achieve high production efficiency, strong continuity, and improved The effect of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

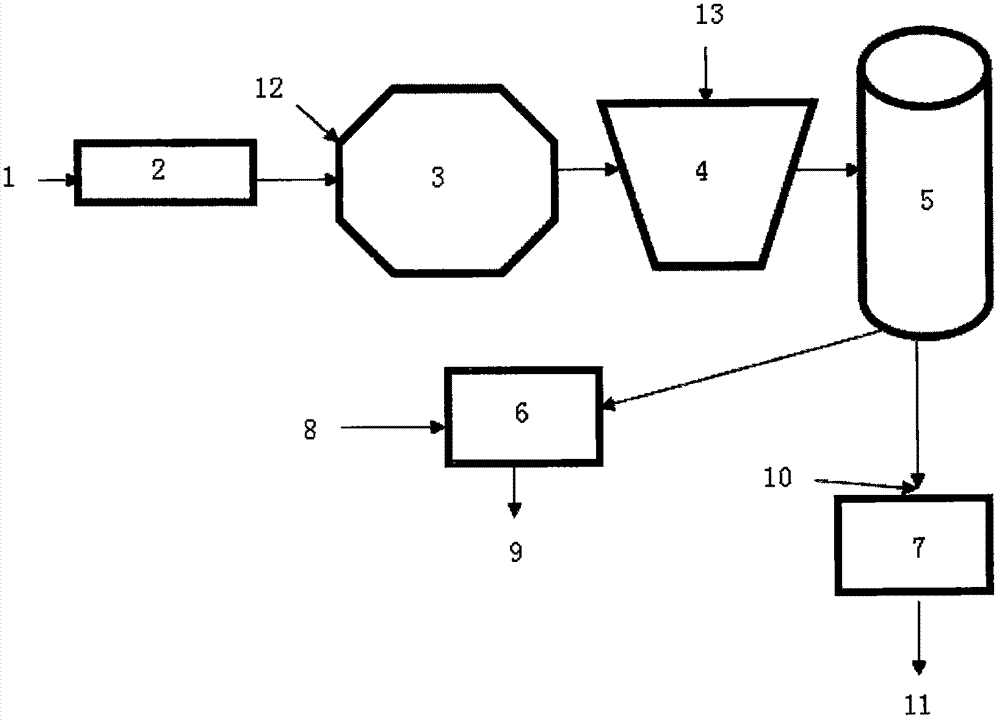

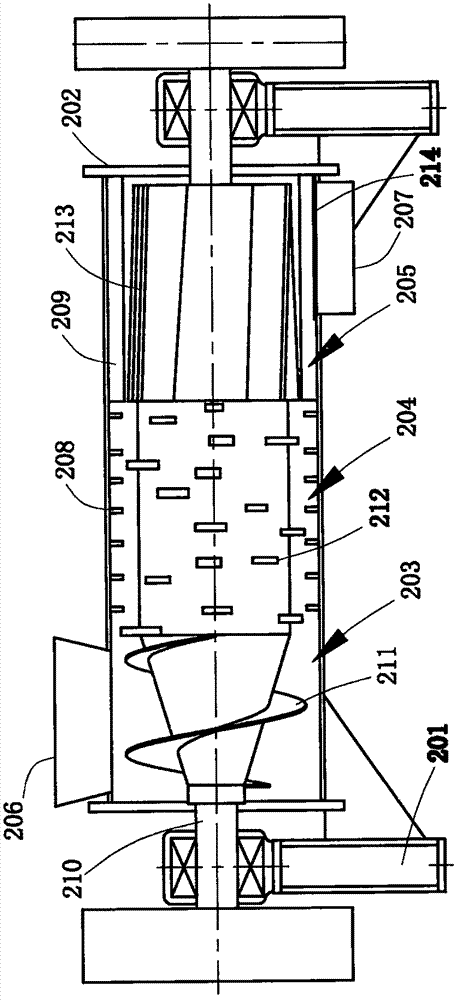

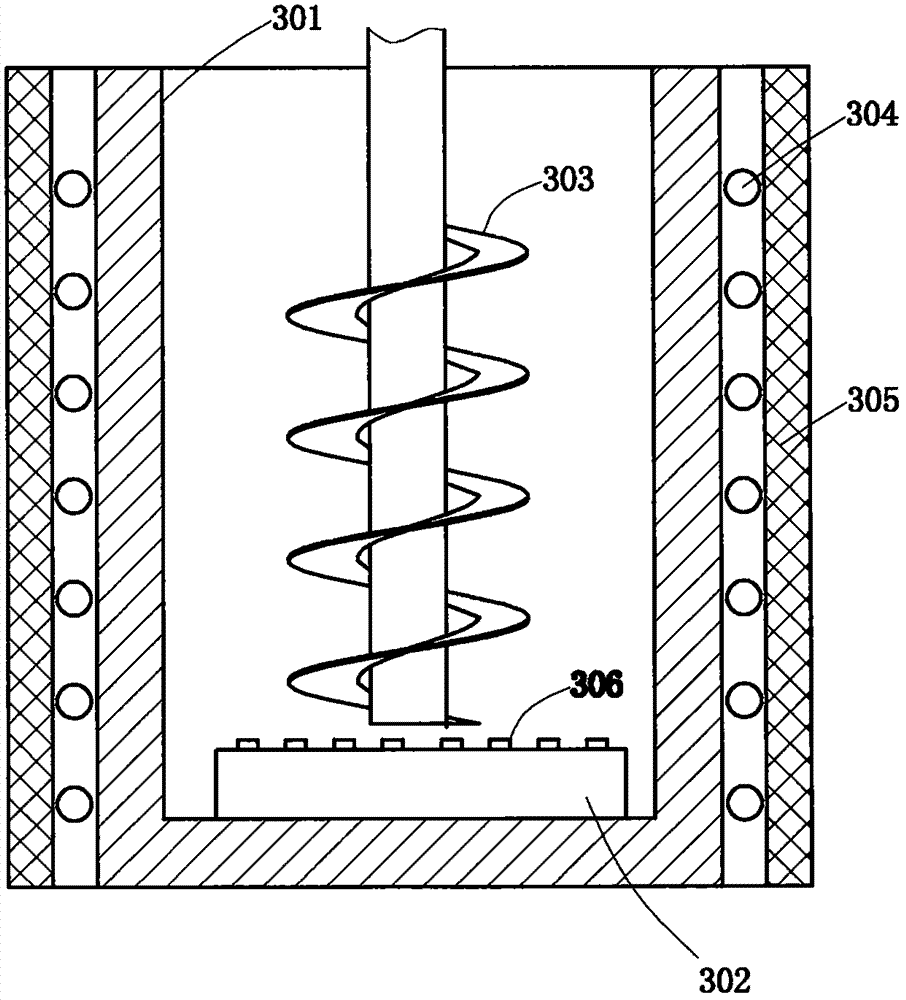

[0067] S1: Provide the above-mentioned fertilizer preparation device, which includes a crushing mixer, an acid reaction kettle, an acid-base adjustment tank, and a solid-liquid separator connected in sequence, and the solid-liquid separator is respectively connected to the downstream concentrator and aerobic composting workshop;

[0068] S2: adding food waste and livestock manure with a mass ratio of 1:1 to the grinding mixer for mixing and grinding to obtain waste organic matter;

[0069] S3: Add the waste organic matter into the acid reaction kettle, and add an aqueous hydrochloric acid solution with a concentration of 10% by mass (wherein, the mass ratio of HCl to the waste organic matter is 1:4), stir evenly, and start the acid reaction The still is heated and stirred (the temperature is shown in Table 1-3 below, and the pressure is 0.15MPa). After the mixture is fully reacted, the heating is stopped and the pressure is released (the reaction time is 20 minutes) to obtain ...

Embodiment 2

[0085] S1: Provide the above-mentioned fertilizer preparation device, which includes a crushing mixer, an acid reaction kettle, an acid-base adjustment tank, and a solid-liquid separator connected in sequence, and the solid-liquid separator is respectively connected to the downstream concentrator and aerobic composting workshop;

[0086] S2: adding food waste and livestock manure with a mass ratio of 1:1 to the grinding mixer for mixing and grinding to obtain waste organic matter;

[0087] S3: Add the waste organic matter into the acid reaction kettle, and add an aqueous hydrochloric acid solution with a concentration of 10% by mass (wherein, the mass ratio of HCl to the waste organic matter is 1:4), stir evenly, and start the acid reaction The kettle is heated and stirred (the temperature is 130°C, and the pressure is shown in the following table 4-6). After the mixture is fully reacted, the heating is stopped and the pressure is released (the reaction time is 20 minutes) to ...

Embodiment 3

[0103] S1: Provide the above-mentioned fertilizer preparation device, which includes a crushing mixer, an acid reaction kettle, an acid-base adjustment tank, and a solid-liquid separator connected in sequence, and the solid-liquid separator is respectively connected to the downstream concentrator and aerobic composting workshop;

[0104] S2: adding food waste and livestock manure with a mass ratio of 1:1 to the grinding mixer for mixing and grinding to obtain waste organic matter;

[0105] S3: Add the waste organic matter into the acid reaction kettle, and add an aqueous hydrochloric acid solution with a concentration of 10% by mass (wherein, the mass ratio of HCl to the waste organic matter is 1:4), stir evenly, and start the acid reaction The kettle is heated and stirred (wherein, the mass ratio of HCl to waste organic matter is 1:4), after stirring evenly, the acid reaction kettle is opened for heating and stirring (the temperature is 130°C, the pressure is 0.15MPa), and af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com