Porous metallic bar

A technology of porous metal and multi-level pores, which is applied in the field of porous metal rods for medical implantation, can solve the problems of weak interface between the implant and adjacent bone tissue, unfavorable fusion of the implant and femur, and unfavorable bone tissue regeneration. , to overcome interface instability, avoid stress shielding, and promote rapid growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

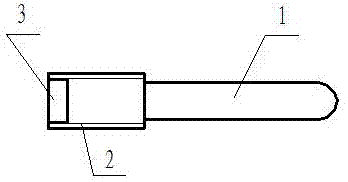

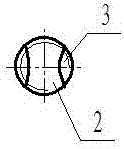

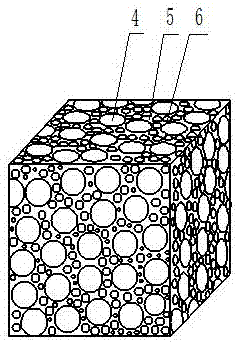

[0025] A porous metal rod made of porous metal material, the porous metal rod consists of two parts, one part is a round rod-shaped part 1, the other part connected to it is a threaded part 2, the outside of which has threads, and the end surface of the threaded part 2 is provided with Notch 3, the outer diameter of the thread is larger than the outer diameter of the round rod. The porous metal material is a multi-level porous metal material. The multi-level porous metal material is divided into two levels. The first-level cavity 4 is a large hole with a diameter of 150 μm. -450µm, in a three-dimensional space surrounding the wall 5 that constitutes the first-stage cavity 4 is composed of a second-stage porous metal material, and the hole diameter of the second-stage porous metal material 6 is 370nm-600nm, and each stage of the cavity is connected to each other It is connected and the cavities at all levels are also connected to each other. The material is stainless steel 316L....

Embodiment 2

[0038] This embodiment is similar to Embodiment 1, except that the material used for the porous metal rod is pure titanium. The cavity 6 has a pore diameter of 450nm-750nm, a porosity of 45%, an elastic modulus of 72GPa, and the overall elastic modulus of the porous metal is 2GPa.

Embodiment 3

[0040] A porous metal rod, which is a multi-level porous metal material made of tantalum metal, has a three-level pore structure. The pore diameter is 300nm-450nm, the pores of each level of porous metal materials are connected to each other and the pores of each level of porous materials are also connected to each other, and the pores of each level of porous metal materials in the multi-level porous metal material The cavities are evenly distributed in the material body, and its preparation method is similar to that of Example 1, except that in the preparation of the porous tantalum material, the mixed particles obtained by crushing, the ethyl cellulose with a particle size of 45µm-75µm are divided by volume After uniform mixing at a ratio of 1:3, it is evenly poured into the three-dimensional polyester foam with a rib diameter of 460µm-580µm and a pore diameter of 600µm-830µm, and then the polyester foam is put into a closed mold and pressed into a dense green body. Vacuum s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com