Method of recyclably pre-treating sludge press filtrate

A technology of sludge press filtration and pretreatment, applied in special treatment targets, chemical instruments and methods, adsorbed water/sewage treatment, etc. Good pretreatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

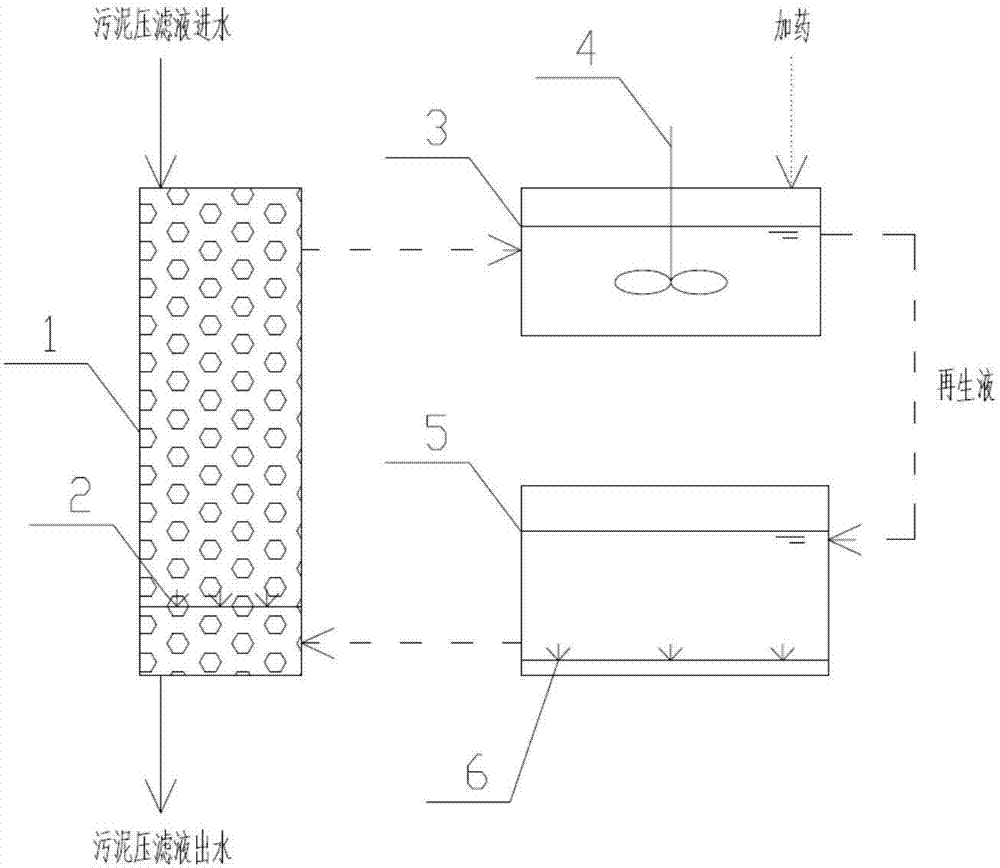

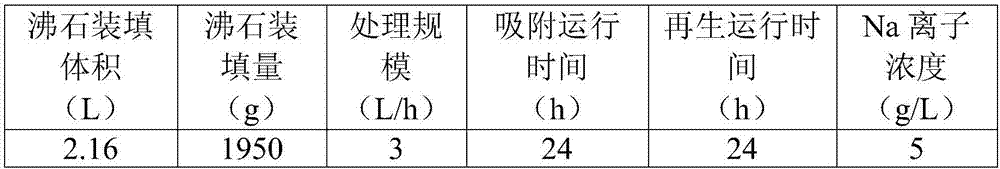

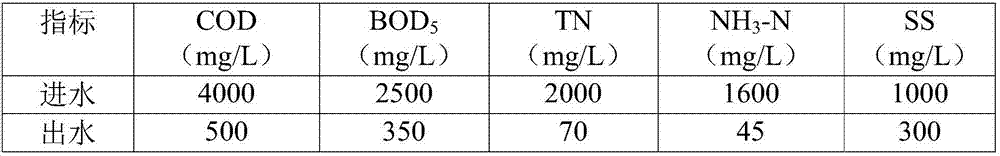

[0029] A method of recyclable pretreatment of sludge press filtrate in this embodiment comprises the following steps, wherein the parameters involved are shown in Table 1:

[0030] (1) Send the sludge press filtrate to the packing adsorption section, and the functional zeolite will adsorb and fix the nitrogen and phosphorus pollutants in the sludge press filtrate on the zeolite, and then flow into the sewage treatment plant for subsequent treatment;

[0031](2) At the same time, the filler adsorption section enters the regeneration stage, and the water quality adjustment section contains regeneration salt solution. The regeneration salt solution is passed into the filler adsorption section, and the nitrogen and phosphorus pollutants on the zeolite are enriched in the regeneration stage through chemical regeneration and ion exchange. In the salt solution, the regeneration of zeolite and the secondary transfer of nitrogen and phosphorus pollutants are realized, and then the regen...

Embodiment 2

[0040] A method for recyclable pretreatment of sludge press filtrate in this embodiment comprises the following steps, wherein the parameters involved are shown in Table 3:

[0041] (1) The sludge press filtrate is sent to the filler adsorption section, and the filler ion exchange resin adsorbs and fixes the nitrogen and phosphorus pollutants in the sludge press filtrate on the ion exchange resin, and then flows into the sewage treatment plant for subsequent treatment;

[0042] (2) At the same time, the filler adsorption section enters the regeneration stage, the water quality adjustment section is filled with regenerated salt solution, and the regenerated salt solution is passed into the filler adsorption section, and the nitrogen and phosphorus pollutants on the ion exchange resin are enriched through chemical regeneration and ion exchange In the regenerated salt solution, the regeneration of the ion exchange resin and the secondary transfer of nitrogen and phosphorus polluta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com