Graphene-oxide aliphatic amine removing agent and application method thereof

An application method and technology of aliphatic amines, applied in graphene oxide fatty amine remover and its application field, can solve problems such as poor effect, high treatment cost, and secondary pollution, so as to protect the ecological environment, improve adsorption performance, and reduce adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0047] This case illustrates the preparation method of graphene oxide suspension.

[0048] 1) Weigh 1.0 g of aphanitic graphite to prepare graphite oxide. The prepared graphite oxide is first acid-washed and washed with water, and finally centrifuged with a centrifuge.

[0049]2) drying the centrifuged graphite oxide with a vacuum freeze drying oven for 48 hours, and grinding the dried graphite oxide into powder.

[0050] 3) Use a FLUKO high-shear dispersing mixer to uniformly disperse 0.2 g of graphene oxide powder in 300 mL of water.

[0051] 4) Exfoliate the graphite oxide solution for 9 minutes with a Cole Parmer (750W, 20KHz) ultrasonic cell pulverizer, and control the amplitude at 30%.

[0052] 5) The stripped suspension was centrifuged at 4000r / min for 20 minutes, and the supernatant was the graphene oxide suspension with a concentration of 0.385g / L.

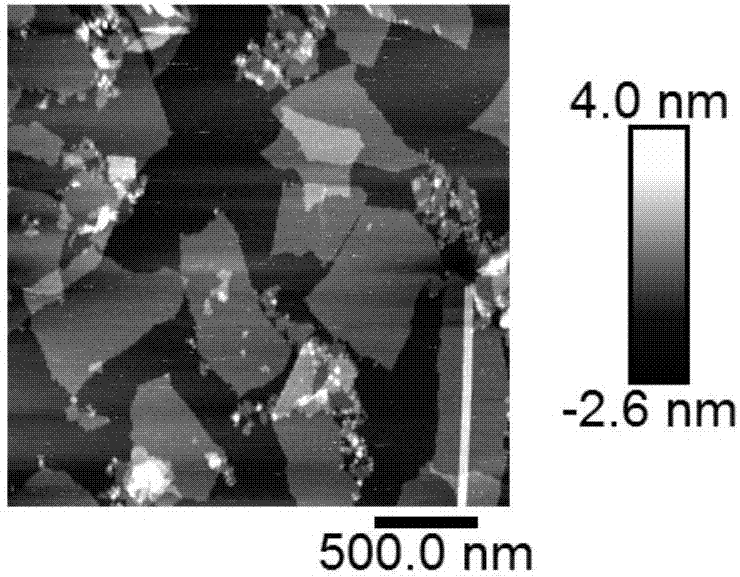

[0053] 6) Product detection: The atomic force micrographs of graphene oxide are shown in Figure 1(a) and Figure 1(b)....

Embodiment example 2

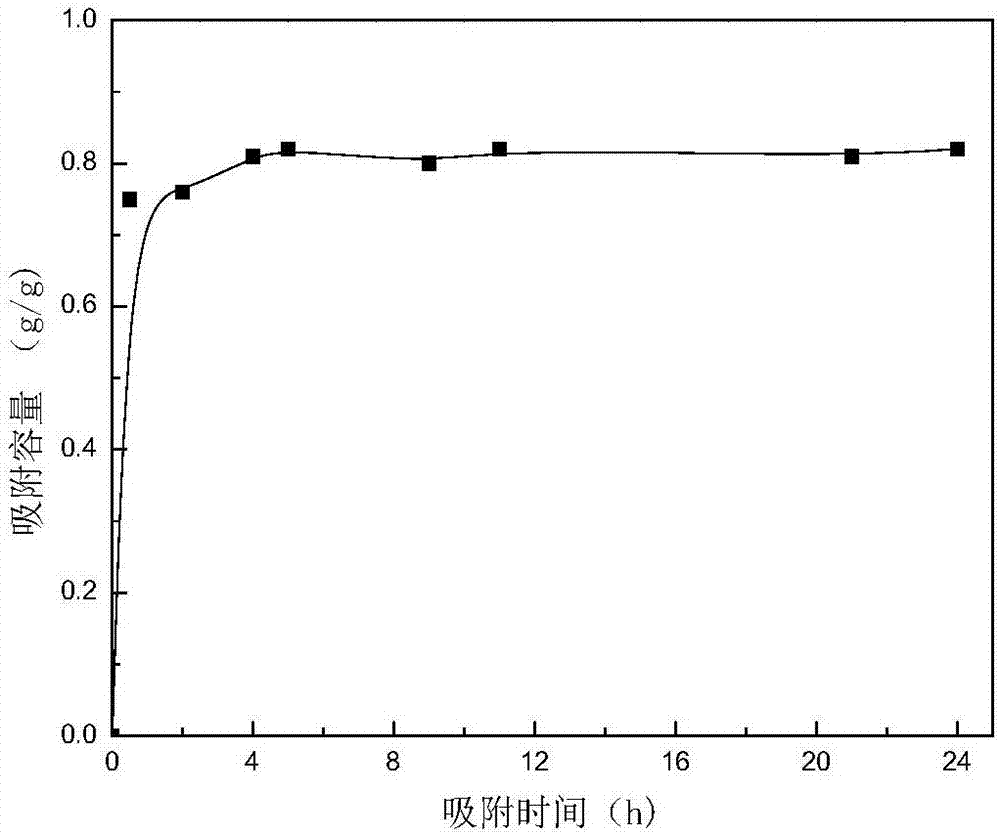

[0055] This case illustrates the adsorption rate of graphene oxide adsorbent.

[0056] 1) Take the dodecylamine wastewater with a concentration of 200mg / L as the object of treatment.

[0057] 2) Mix the graphene oxide suspension (10 mL) prepared in Case 1 with 200 mg / L dodecylamine wastewater (40 mL) in a conical flask.

[0058] 3) Put the Erlenmeyer flask on the shaker, at the adsorption reaction temperature of 25°C and the shaking speed of 150rpm, the adsorption and removal times are 0.25h, 1.5h, 3h, 5h, 9h, 11h, 21h and 24h respectively.

[0059] 4) Take out the Erlenmeyer flask after the adsorption reaction is completed from the oscillator, filter the graphene oxide suspension with a filter head with a pore size of 0.22 microns to obtain the purified solution after adsorption treatment, and then measure its dodecylamine with a UV spectrophotometer residual concentration in the purified solution.

[0060] 5) According to the formula: the adsorption capacity of graphene ox...

Embodiment example 3

[0063] This case illustrates the effect of temperature and dodecylamine concentration on the adsorption capacity of graphene oxide adsorbent.

[0064] 1) Take the concentration of 0mg / L, 40mg / L, 80mg / L, 120mg / L, 160mg / L, 200 mg / L, 240mg / L, 280mg / L, 320mg / L, 360mg / L, 400mg / L Dodecylamine wastewater, as the object of treatment.

[0065] 2) Mix the graphene oxide suspension (10 mL) prepared in Case 1 with 200 mg / L dodecylamine wastewater (40 mL) in a conical flask.

[0066] 3) Put the Erlenmeyer flask on the shaker, at the adsorption reaction temperature of 25° C., 35° C., and 45° C., at the shaking speed of 150 rpm, and the adsorption and removal time is 24 hours.

[0067] 4) Take out the Erlenmeyer flask after the adsorption reaction is completed from the oscillator, filter the graphene oxide suspension with a filter head with a pore size of 0.22 microns to obtain the purified solution after adsorption treatment, and then measure its dodecylamine with a UV spectrophotometer r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com