Bioleaching reinforcing agent, and method used for removing sludge heavy metal

A biological leaching, heavy metal technology, applied in biological sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of shortening the sludge treatment period, increasing the sludge treatment cost, and the cost of bacterial culture. It can achieve the effect of promoting the dissolution of heavy metals, killing pathogenic bacteria in sludge, and improving the dissolution efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for utilizing free nitrous acid to strengthen biological leaching to remove heavy metals in sludge, comprising the steps of:

[0041] (1) Sludge bioleaching: Add 270mL of test sludge 1 with a solid content of 20g / L in a 500mL conical flask, inoculate 30mL of domesticated bioleaching culture 1, and then add 1g of elemental sulfur, Shaking culture at room temperature 200r / min for 2 days, the pH value of the sludge dropped to 2.53;

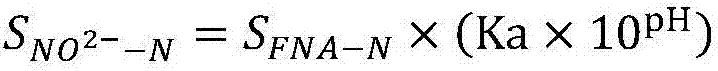

[0042] (2) Free nitrous acid reaction: add 63.80mgNaNO to the sludge treated by bioleaching 2 (equivalent to 20mgFNA-N / L), 30°C, 200r / min shaking culture for 8h; the dissolution rates of heavy metals Cu, Zn, Pb, Cd, Mn and Co in the sludge were 55.48%, 93.69%, 5.26%, 64.38% respectively %, 50.69%, 47.96%;

[0043] (3) Sludge dehydration: the treated sludge is dehydrated by centrifugal dehydration; the moisture content of the treated sludge is 74.8%;

[0044] (4) Removal of heavy metals in the filtrate: add an appropriate amount of ...

Embodiment 2

[0046] A method for utilizing free nitrous acid to strengthen biological leaching to remove heavy metals in sludge, comprising the steps of:

[0047] (1) Sludge bioleaching: Add 270mL of test sludge 1 with a solid content of 20g / L in a 500mL conical flask, inoculate 30mL of domesticated bioleaching culture 1, and then add 1g of elemental sulfur, Shaking culture at room temperature 200r / min for 2 days, the pH value of the sludge dropped to 2.53;

[0048] (2) Free nitrous acid reaction: add 127.60mgNaNO to the sludge treated by bioleaching 2 (equivalent to 40mgFNA-N / L), 30°C, 200r / min shaking culture for 8h; the dissolution rates of heavy metals Cu, Zn, Pb, Cd, Mn and Co in the sludge were 56.13%, 94.28%, 6.31%, 65.89% respectively %, 54.37%, 49.45%;

[0049] (3) Sludge dehydration: the treated sludge is dehydrated by centrifugal dehydration; the moisture content of the treated sludge is 73.5%;

[0050] (4) Removal of heavy metals in the filtrate: add an appropriate amount of...

Embodiment 3

[0052] A method for utilizing free nitrous acid to strengthen biological leaching to remove heavy metals in sludge, comprising the steps of:

[0053] (1) Sludge bioleaching: Add 255mL of test sludge 1 with a solid content of 20g / L in a 500mL Erlenmeyer flask, inoculate 45mL of domesticated bioleaching culture 1, and then add 1.5g of elemental sulfur , 150r / min shaking culture at room temperature for 3 days, the pH value of the sludge dropped to 2.08;

[0054] (2) Free nitrous acid reaction: add 60.78mgNaNO to the sludge treated by bioleaching 2 (equivalent to 20mgFNA-N / L), 30°C, 150r / min shaking culture for 6h; the dissolution rates of heavy metals Cu, Zn, Pb, Cd, Mn and Co in the sludge were 58.36%, 95.52%, 5.98%, 67.79% respectively %, 52.49%, 50.32%;

[0055] (3) Sludge dehydration: the treated sludge is dehydrated by centrifugal dehydration, and the moisture content of the treated sludge is 72.3%;

[0056] (4) Removal of heavy metals in the filtrate: add an appropriate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com