Preparation and application of a rapid film-forming energy-saving and environmental protection machine spray fine decoration mortar

An energy-saving, environment-friendly, and film-forming technology, applied in the field of phase-change mortar materials, can solve the problems of single phase-change materials and mortar with low film-forming properties, and achieve high throwing power, improved flexibility, and stable and uniform phase change properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

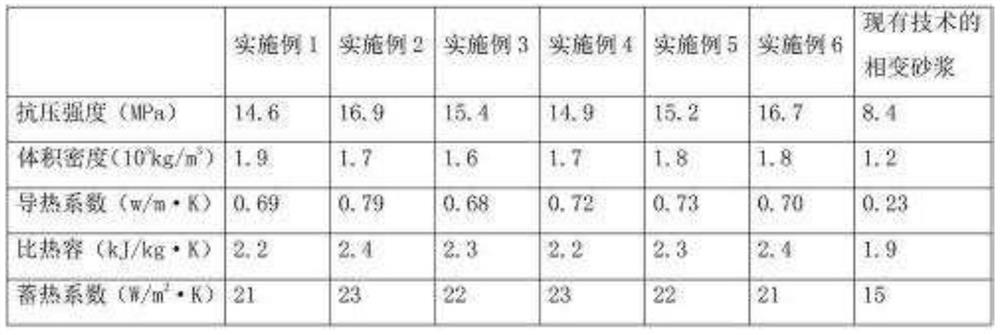

Examples

Embodiment 1

[0024] (1) Mix pentaerythritol particle solid phase change material and saturated fatty acid liquid phase change material according to the mass percentage of 30%:70%, heat and melt at 170°C, add antioxidant and ceramsite adsorption material, and adsorb at 80°C for 6h After reaching saturation, according to the mass ratio of film-forming agent and adsorbent as 1:1.8, add porous graphite sheet thermal conductivity additive and polybutadiene-modified epoxy resin film-forming agent, mix evenly, solidify and form, and cool to room temperature , to obtain a solid-liquid phase change material.

[0025] (2) In parts by weight, 150 parts of white cement, 120 parts of diatomaceous earth, 10 parts of non-ionic emulsifier, molecular weight of 1800-2300, epoxy oxygen content of 7-8% epoxy polybutane 50 parts of alkene, 100 parts of gypsum and 160 parts of solid-liquid phase change material were added to 250 parts of water, mixed evenly, solidified and molded, removed from the mold, and mai...

Embodiment 2

[0027] (1) The high-density polyethylene particle solid phase change material and the capric acid liquid phase change material are mixed according to the mass percentage of 70%:30%, heated and melted at 190° C., adding antioxidants and diatomite adsorption materials, at 90 After adsorption at ℃ for 8 hours to saturation, according to the mass ratio of film-forming agent and adsorbent as 1:2, add short carbon fiber thermal conductivity additive and polybutadiene-modified epoxy resin film-forming agent, mix evenly, and cure and form , cooled to room temperature to obtain a solid-liquid phase change material.

[0028] (2) In parts by weight, 200 parts of white cement, 150 parts of diatomaceous earth, 20 parts of nonionic emulsifier, molecular weight of 1800-2300, epoxy oxygen content of 7-8% epoxy polybutylene 80 parts of alkene, 150 parts of gypsum and 180 parts of solid-liquid phase change material were added to 400 parts of water, mixed evenly, solidified and molded, removed f...

Embodiment 3

[0030] (1) Mix the sliced paraffin solid phase change material and the stearic acid liquid phase change material according to the mass percentage of 45%:55%, heat and melt at 180°C, add antioxidants and ceramsite adsorption materials, and adsorb at 85°C After 7 hours to saturation, according to the mass ratio of film-forming agent and adsorbent as 1:1.9, add short carbon fiber thermal conductivity additive and polybutadiene-modified epoxy resin film-forming agent, mix evenly, solidify and form, and cool to At room temperature, a solid-liquid phase change material is obtained.

[0031](2) In parts by weight, 180 parts of white cement, 140 parts of diatomaceous earth, 15 parts of nonionic emulsifier, molecular weight of 1800-2300, epoxy oxygen content of 7-8% epoxy polybutylene 60 parts of alkene, 130 parts of gypsum and 170 parts of solid-liquid phase change material were added to 300 parts of water, mixed evenly, solidified and molded, removed from the mold, and maintained f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com