Preparation method of whole straw foaming material

A production method and foaming material technology are applied in the fields of paper pulping and foaming, which can solve the problems of pollution in the production process and high production cost, and achieve the effects of no pollution, reliable quality, considerable social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

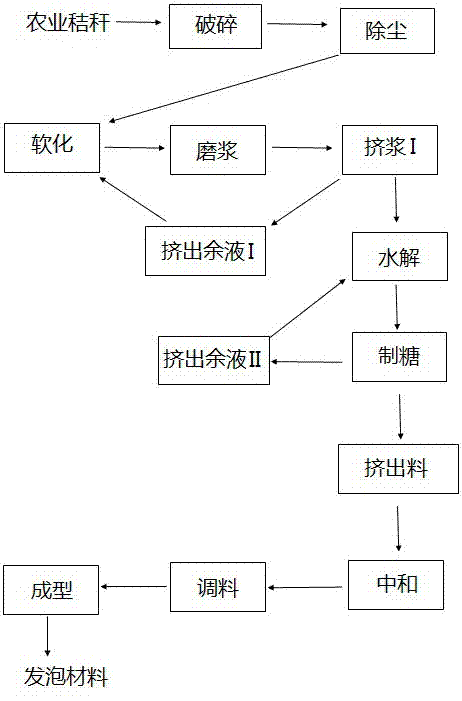

Image

Examples

Embodiment

[0069] The implementation steps of this embodiment refer to the attached figure 1 . The equipment used and their models are:

[0070] 1. Crusher: HCF400

[0071] 2. Spiral dust collector: self-designed and manufactured (304#)

[0072] 3. Stock silo: self-designed and manufactured (304#)

[0073] 4. Refiner: YZJM-380

[0074] 5. Pulping machine: RBYL-1000 belt filter press

[0075] 6. Hydrolysis tower: TGPT-10

[0076] 7. Neutralization pool: self-designed and manufactured (304#)

[0077] 8. Seasoning pool: self-designed and manufactured (304#)

[0078] 9. Medicine pool Ⅰ and Ⅱ: self-designed and manufactured (304#)

[0079] 10. Molding machine: self-designed and manufactured (refer to national patents ZL 2012 20231867.4, ZL20142064838.7)

[0080] In this embodiment, straw is used as a raw material to make a foam packaging material. The specific steps are as follows. Unless otherwise specified, the percentages in the present invention refer to weight percentages.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com