Aqueous sterilizing and blue light resisting coating for tempered glass screen protectors, and preparation method thereof

An anti-blue light and tempered film technology, applied in the field of coatings, can solve the problems of inability to effectively achieve the purpose of sterilization and anti-blue light, and achieve the effects of strong adhesion, high hardness and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In one embodiment, the preparation method at least includes the following steps:

[0053] (1) Take each raw material component according to the raw material ratio of the water-based bactericidal anti-blue light coating for the tempered film;

[0054] (2) 40-60% of the deionized water, 40-60% of the pH regulator, dispersant, 40-60% of the defoamer, nano-barium sulfate, nano-zinc oxide, organic silicone powder, dazzle The color pigment, silica sol, and blue light absorber are mixed to obtain the first mixed material;

[0055] (3) Under stirring conditions, the water-based hydroxyacrylic acid emulsion, nano glass resin, amino resin, film-forming aid, remaining pH regulator, remaining defoamer, remaining deionized water, substrate wetting agent are mixed Material processing to obtain the second mixed material;

[0056] (4) Mix the first mixed material and the second mixed material, disperse, add a thickener, and stir to obtain a water-based bactericidal anti-blue light co...

Embodiment 1

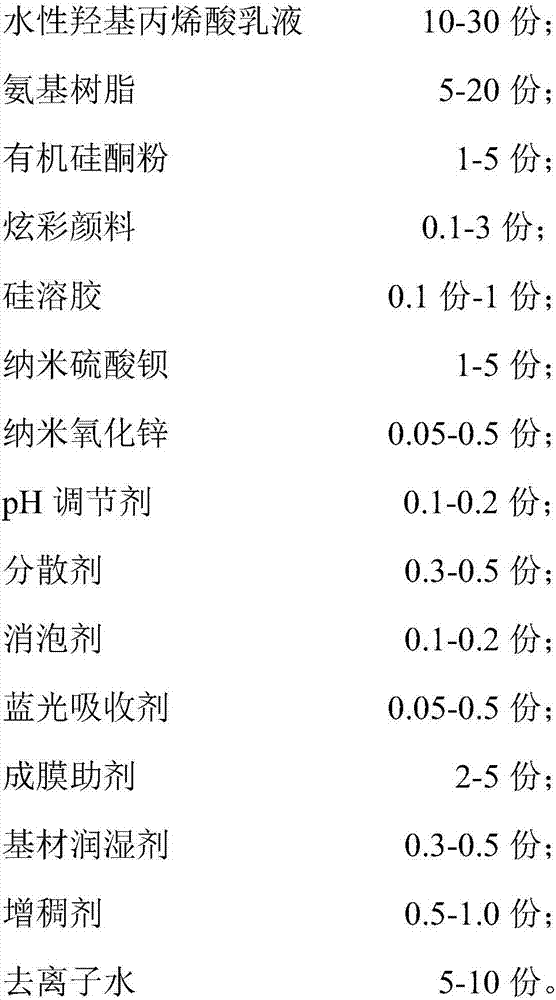

[0062] Water-based bactericidal anti-blue light coating for tempered film, including raw material components with the following mass fractions:

[0063]

[0064] The preparation method comprises the following steps:

[0065] (1) Take each raw material component according to the raw material ratio of the water-based bactericidal anti-blue light coating for the tempered film;

[0066] (2) 50% of the deionized water, BT-9273 silicone powder, BL-series laser ink, JN20-30-6, Sachtleben micro nano-barium sulfate, nano-zinc oxide powder, 50% of dimethylethanolamine %, AFCONA-5010, 50% of the equal proportion mixture of 941PL and BYK-028 from MOUSSEX company, and Jiedeying BL 1227 were mixed, and stirred at 1000r / min for 10min to obtain the first mixed material;

[0067] (3) Under the stirring condition of 500r / min, 1 part of 2227 / 1 of Bayer, 4GU-T55 of Shanghai Huzheng Nano Technology Co., Ltd., Cymel 325, A5 and alcohol ester-12 film-forming aid of the United States were mixed. ...

Embodiment 2

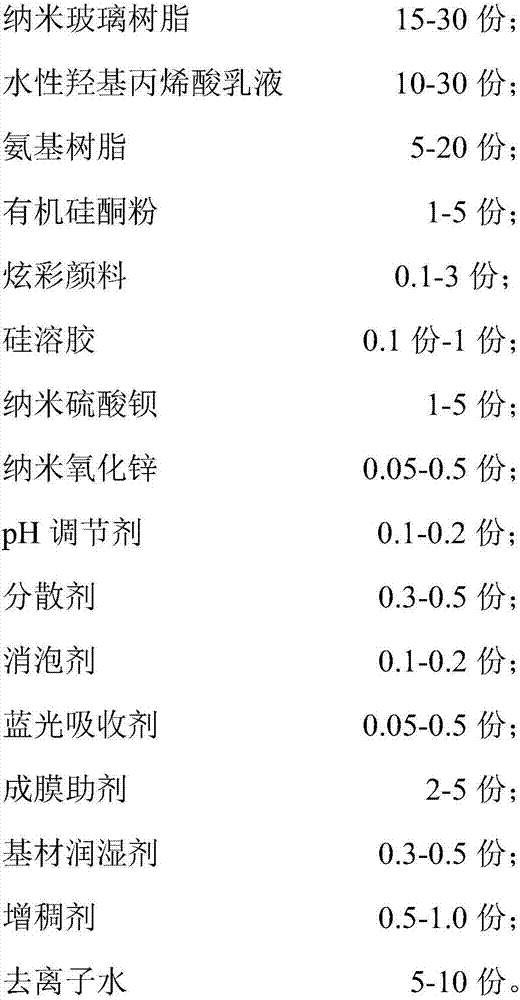

[0070] Water-based bactericidal anti-blue light coating for tempered film, including raw material components with the following mass fractions:

[0071]

[0072]

[0073] The preparation method comprises the following steps:

[0074] (1) Take each raw material component according to the raw material ratio of the water-based bactericidal anti-blue light coating for the tempered film;

[0075] (2) 60% of the deionized water, BT-9273 silicone powder, BL-series laser ink, JN20-30-6, Sachtleben micro nano-barium sulfate, nano-zinc oxide powder, 60% of dimethylethanolamine %, AFCONA-5010, 60% of the equal proportion mixture of 941PL and BYK-024 from MOUSSEX company, and Jiedeying BL 1227 were mixed, and stirred at 900r / min for 12min to obtain the first mixed material;

[0076] (3) Under the stirring condition of 400r / min, 1 part of 2227 / 1 of Bayer, 4GU-T55 of Shanghai Huzheng Nano Technology Co., Ltd., Cymel 325, A5 and alcohol ester-12 film-forming aid of the United States w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com