Anti-freezing solution for low-temperature anti-rusting vehicle

A technology for antifreeze and vehicles, applied in metal material coating process, heat exchange materials, chemical instruments and methods, etc., can solve the problem of reducing the pH value of antifreeze, low flash point, and increasing the corrosion of metal parts by antifreeze and other problems, to achieve strong barrier ability and the effect of inhibiting metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

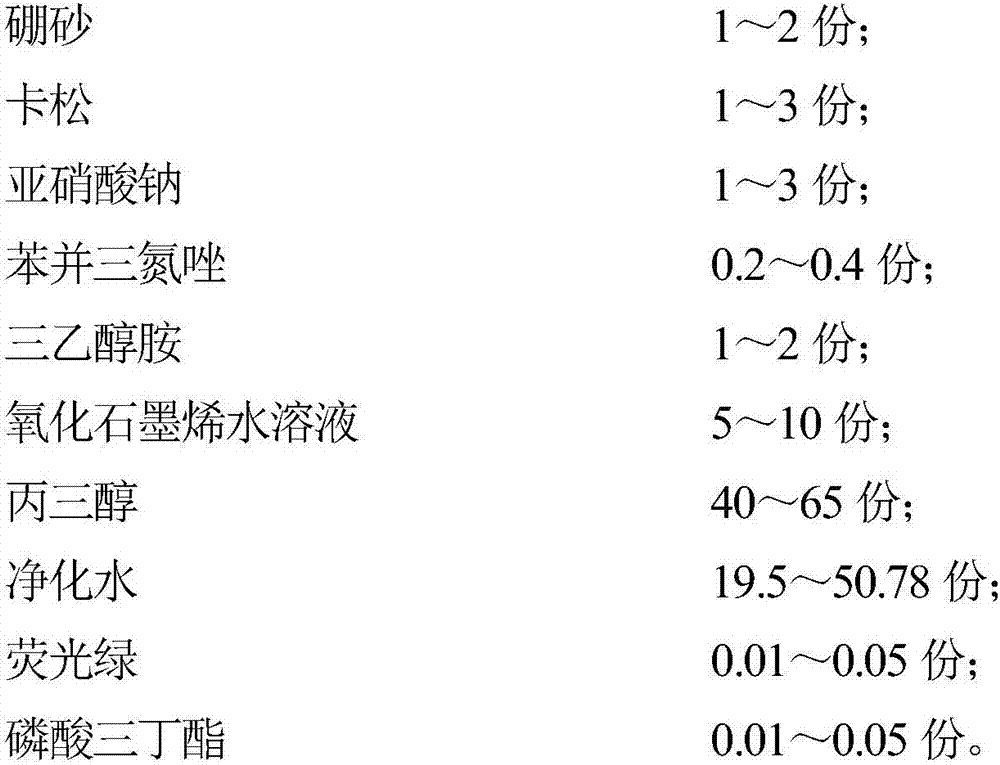

[0018] In this embodiment, the low-temperature anti-rust vehicle antifreeze is prepared by mixing the following materials uniformly by weight:

[0019]

[0020] The graphene oxide aqueous solution is prepared by using the Hummer method and then ultrasonically dispersed to form an aqueous solution, the solid content of which is 0.2 wt % to 0.3 wt %, and the graphene oxide sheet diameter is 1 to 5 μm.

[0021] When preparing, borax and benzotriazole are first dissolved in hot water, and the function is to fully dissolve benzotriazole and borax, and then mix with other components after being placed at room temperature.

[0022] In this embodiment, the low-temperature anti-rust vehicle antifreeze has good stability and low temperature resistance. In addition, a passivation protective film can be formed on the surface of the cooled metal to inhibit metal corrosion.

Embodiment 2

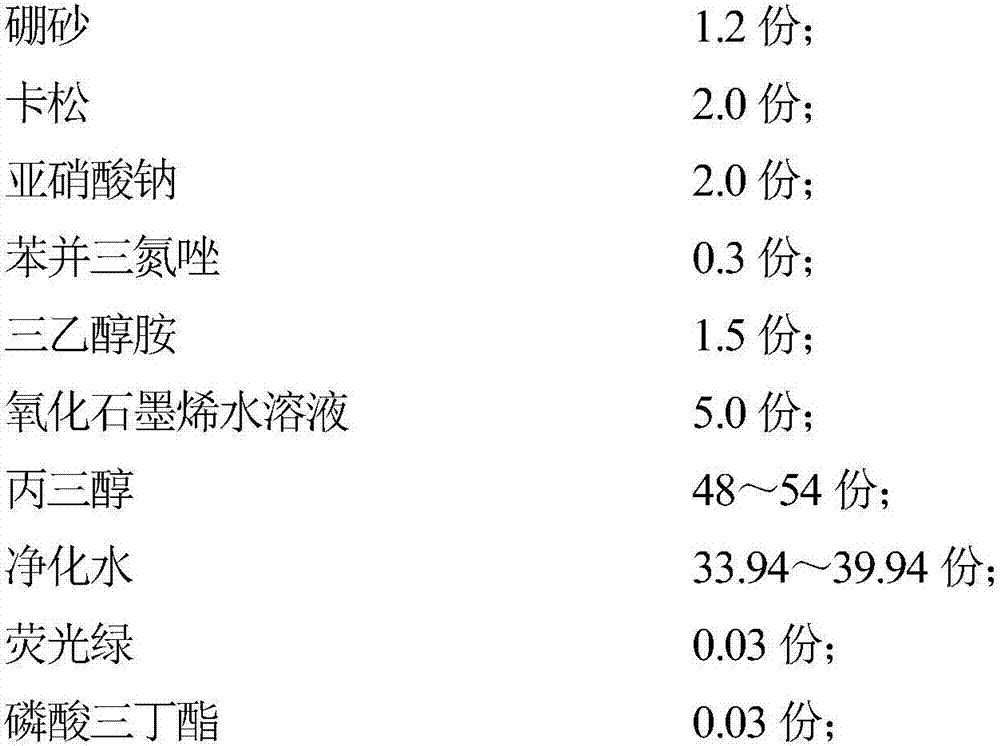

[0024] In this embodiment, the low-temperature anti-rust vehicle antifreeze is prepared by mixing the following materials uniformly by weight:

[0025]

[0026] The graphene oxide aqueous solution is prepared by using the Hummer method and then ultrasonically dispersed to form an aqueous solution, the solid content of which is 0.2 wt % to 0.3 wt %, and the graphene oxide sheet diameter is 1 to 5 μm.

[0027] When preparing, borax and benzotriazole are first dissolved in hot water, left to room temperature and mixed with other components.

[0028] In this embodiment, the low-temperature anti-rust vehicle antifreeze has good stability and low temperature resistance. In addition, a passivation protective film can be formed on the surface of the cooled metal to inhibit metal corrosion.

Embodiment 3

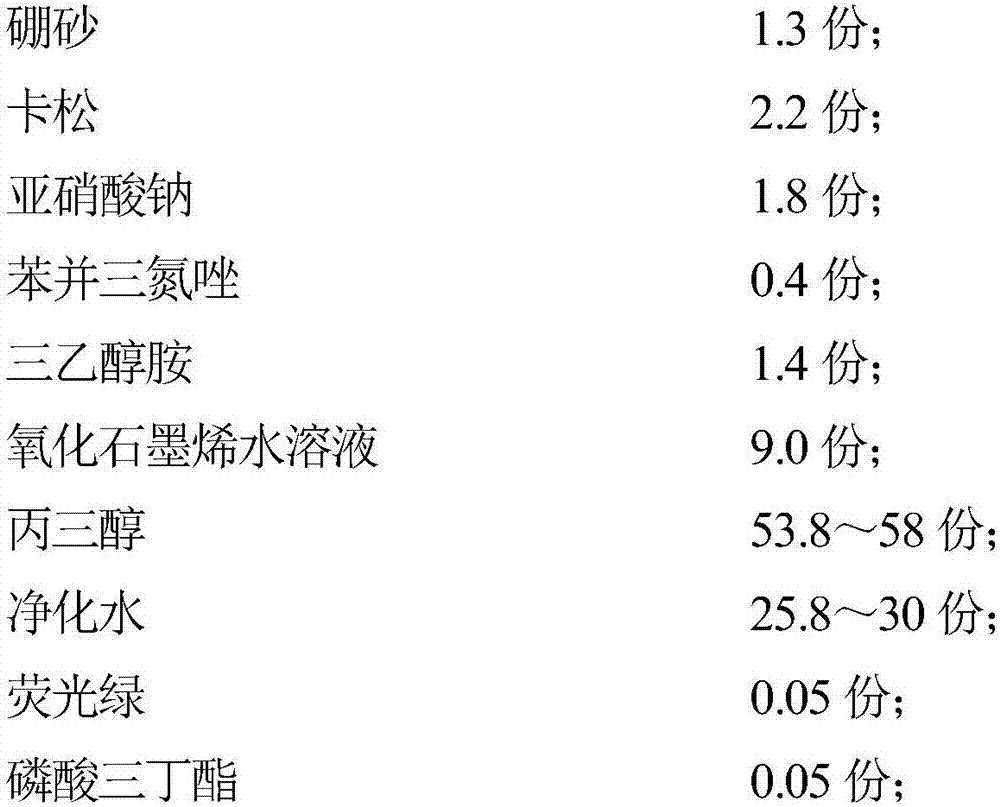

[0030] In this embodiment, the low-temperature anti-rust vehicle antifreeze is prepared by mixing the following materials uniformly by weight:

[0031]

[0032] The graphene oxide aqueous solution is prepared by using the Hummer method and then ultrasonically dispersed to form an aqueous solution, the solid content of which is 0.2 wt % to 0.3 wt %, and the graphene oxide sheet diameter is 1 to 5 μm.

[0033] When preparing, borax and benzotriazole are first dissolved in hot water, left to room temperature and mixed with other components.

[0034] In this embodiment, the low-temperature anti-rust vehicle antifreeze has good stability and low temperature resistance, its application range is -30°C to -40°C, and the boiling point range is 106°C to 112°C. It is not volatile and does not block pipes. In addition, a passivation protective film can be formed on the surface of the cooled metal to inhibit metal corrosion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com