Combined contaminated soil restoration system and using method thereof

A technology of composite pollution and restoration system, applied in the restoration of polluted soil and other directions, can solve the problems of easy blockage of isolation devices, poor treatment effect, low mass transfer efficiency, etc., to prevent direct pollution, save costs, and improve mass transfer efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

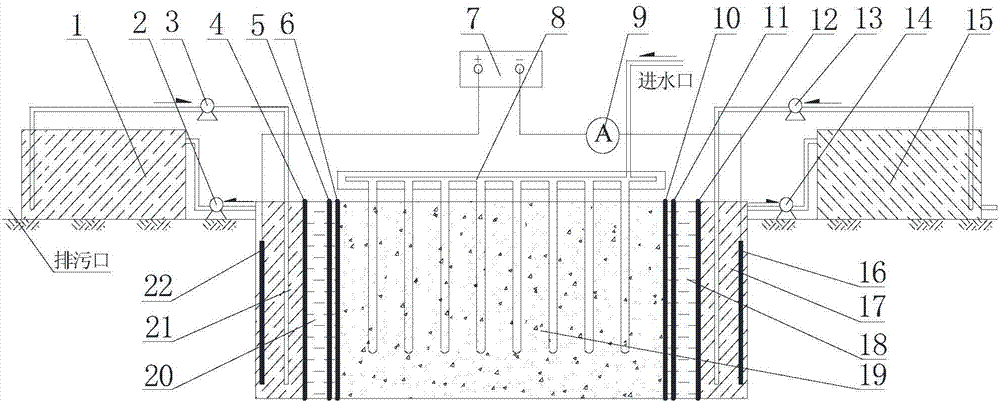

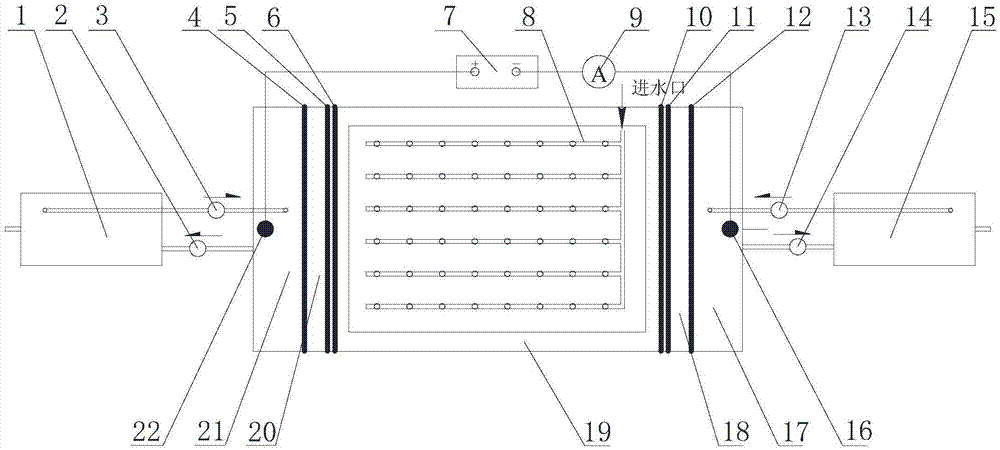

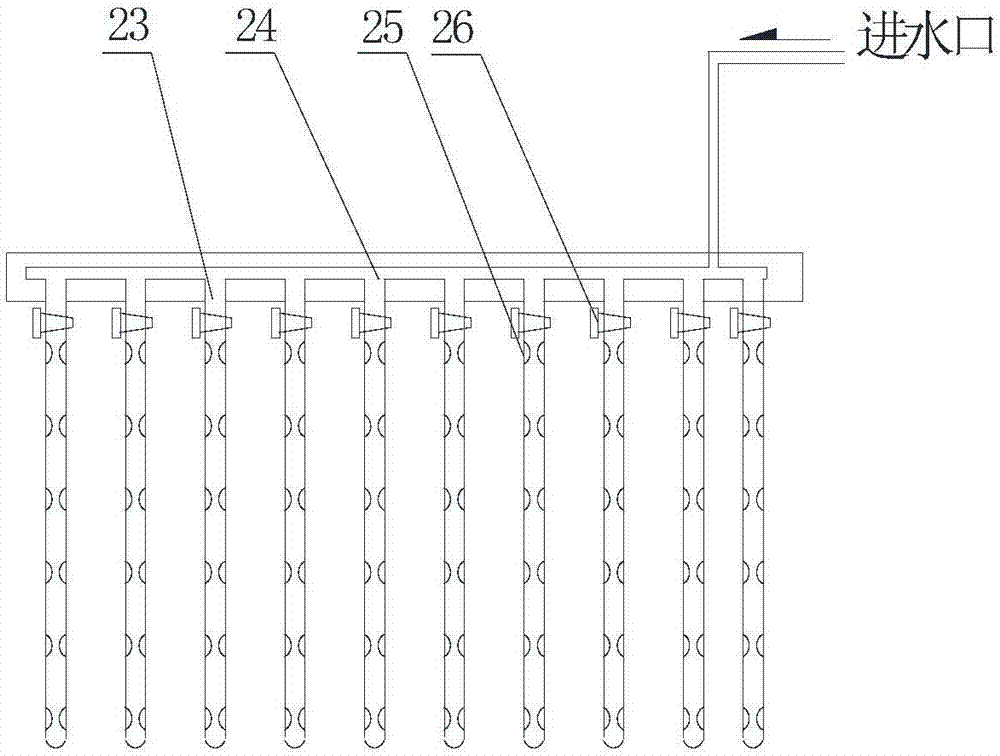

[0035] A remediation system for composite polluted soil and its application method. A rain-proof shed is set up above the composite polluted soil 19 to be repaired; figure 1 and figure 2 As shown, the surface of the compound polluted soil 19 to be repaired is provided with a moisture content controller 8; the left side of the compound polluted soil 19 to be repaired is provided with an anode permeable reaction wall and an anode tank 21 sequentially from the inside to the outside. The right side of the composite polluted soil 19 is provided with a cathode permeable reaction wall and a cathode tank 17 sequentially from the inside to the outside.

[0036] Such as figure 1 and figure 2 As shown, the anode permeable reaction wall, the anode tank 21, the compound polluted soil 19 to be repaired, the anode tank 21 and the cathode tank 17 are a rectangular block. Anode permeable reaction wall: anode tank 21: compound polluted soil to be repaired 19: cathode tank 17: the area rat...

Embodiment 2

[0052] A remediation system for composite polluted soil and its application method. Except following technical parameter, all the other are with embodiment 1:

[0053] The anode permeable reaction wall: anode tank 21: complex polluted soil to be repaired 19: cathode tank 17: the area ratio of the cathode permeable reaction wall is 1:1~2:5~30:1~2:1 .

[0054] The voltage of the constant voltage DC power supply 7 is 0.8 ~ 1.3V / cm 2 .

[0055] The moisture content of the composite polluted soil 19 to be repaired in the system is 38-43%.

[0056] The hourly circulation flow rate of the cathode buffer solution and the anode buffer solution is 3 to 8 times the volume of the cathode tank, and the circulation time is 7 to 15 days, at the 1.3 to 1.8 days of the circulation flow.

[0057] The enzyme activity of the laccase enzyme solution is 10-30 U / mL.

[0058] The volume ratio of the laccase:ABTS:anode buffer solution is (0.1-0.8):(0.1-0.8):1.

[0059] The volume ratio of the la...

Embodiment 3

[0063] A remediation system for composite polluted soil and its application method. Except following technical parameter, all the other are with embodiment 1:

[0064] The anode permeable reaction wall: anode tank 21: complex polluted soil to be repaired 19: cathode tank 17: the area ratio of the cathode permeable reaction wall is 1: (2~3): (25~50): ( 2~3): 1.

[0065] The voltage of the constant voltage DC power supply 7 is 1.0~1.5V / cm 2 .

[0066] The composite polluted soil 19 to be repaired in the system has a water content of 40-45%.

[0067] The hourly circulation flow rate of the cathode buffer solution and the anode buffer solution is 5-10 times of the volume of the cathode tank, and the circulation time is 12-20 days, which is in the 1.5-2.0 days of the circulation flow.

[0068] The enzyme activity of the laccase enzyme solution is 20-40 U / mL.

[0069] The volume ratio of the laccase:ABTS:anode buffer solution is (0.5-1):(0.5-1.0):1.

[0070] The volume ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com