Method for improving fiber laser welding heat efficiency of red copper based on power modulation

A power modulation, fiber laser technology, used in laser welding equipment, welding equipment, manufacturing tools and other directions, can solve the problems of low, no more than 5% at room temperature, high equipment input cost, limited laser application, etc., to improve thermal efficiency, The effect of improving energy transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

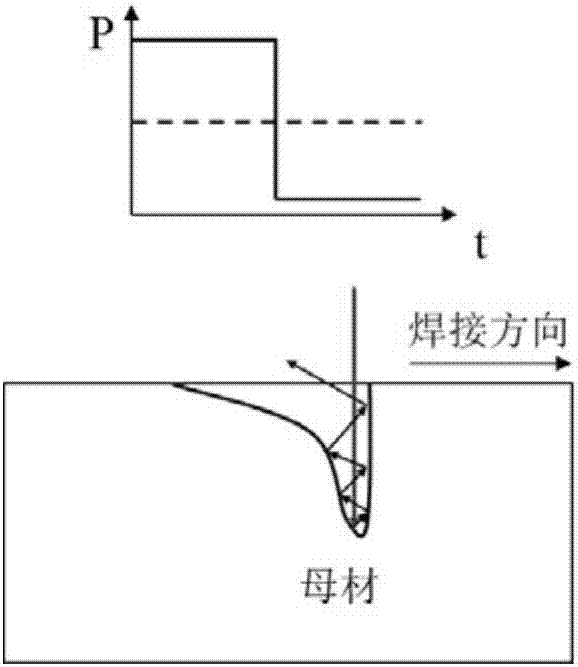

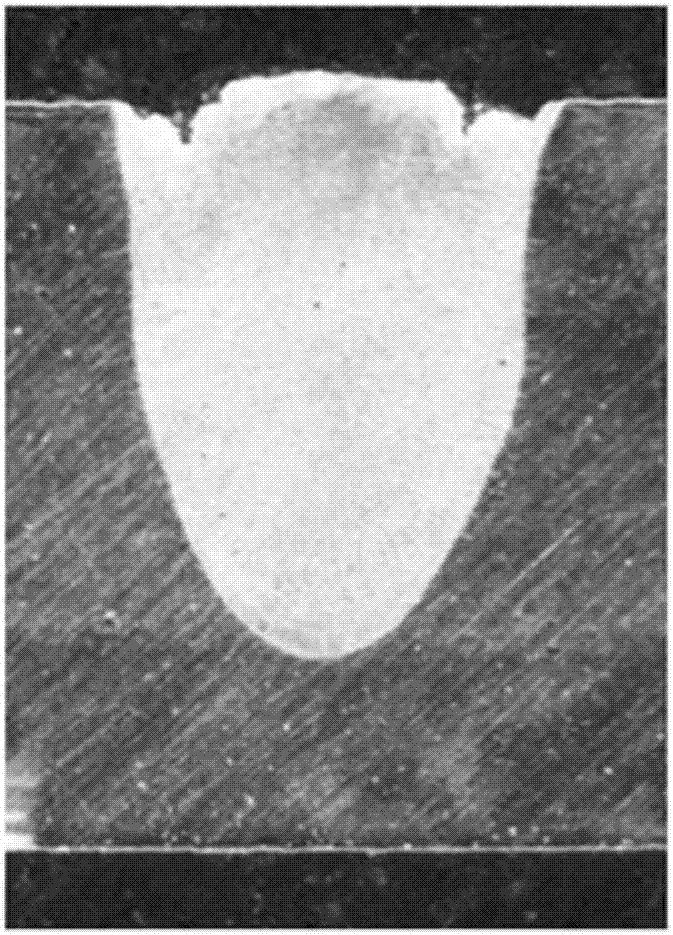

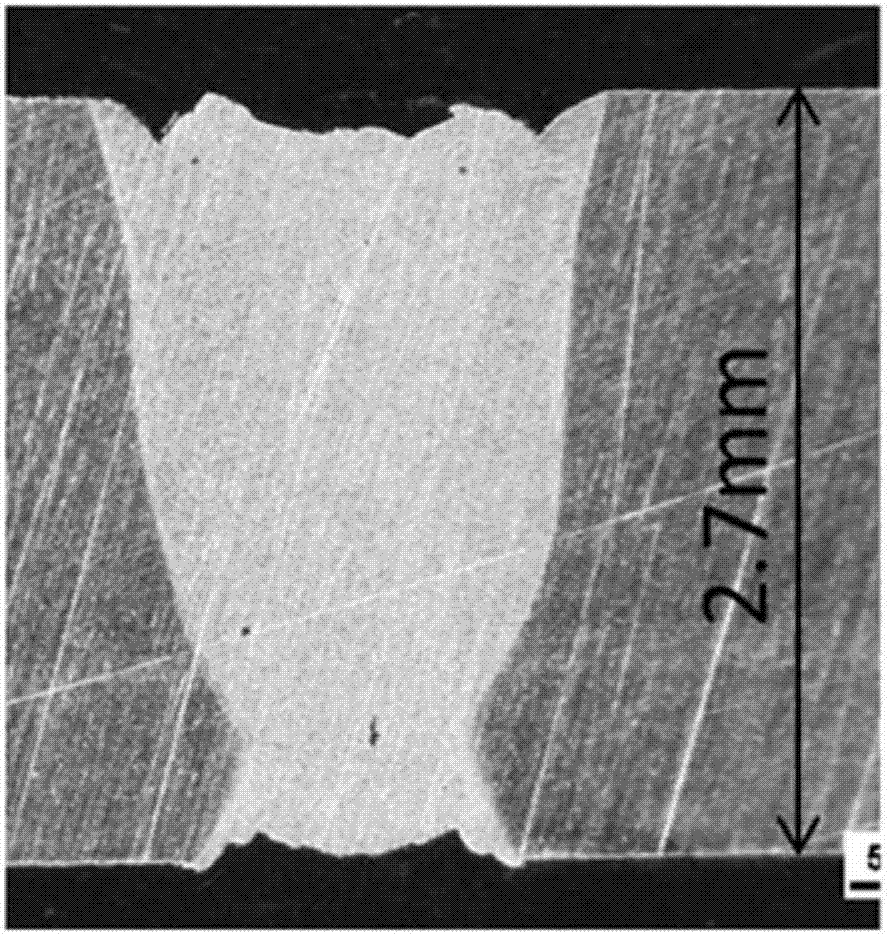

[0025] The test material is AZ31 magnesium alloy, and the thickness of the test plate is 2.7mm. Before the test, the oxide layer on the surface of the material is removed by sanding, and wiped clean with acetone. The welding speed is 5m / min, the defocus is 0mm, and the laser head is inclined at 10° to irradiate the surface of the test plate. The first scheme is: without modulating the laser power, the 2.0kW laser beam is directly irradiated on the surface of the test plate to form a continuous weld bead, and the metallographic sample of the cross-section of the weld is intercepted to obtain the following Figure 2a The results shown; the second scheme is: use sine wave to modulate the laser power, the modulation frequency is 300HZ, the amplitude is 1.5kW, the average power is 2.0kW, to form a continuous weld bead, and intercept the metallographic sample of the weld cross section get as Figure 2b The results shown. from Figure 2a and Figure 2b It can be seen that the met...

Embodiment 2

[0027] The test material is T2 red copper, and the thickness of the test plate is 1.5mm. Before the test, sand the oxide layer on the surface of the material, and wipe it clean with acetone. The welding speed is 1m / min, the defocus is 0mm, and the laser head is tilted at 10° to irradiate the surface of the test plate. The first scheme is: without modulating the laser power, the 2.5kW laser beam is directly irradiated on the surface of the test plate to form a continuous weld bead, and the metallographic sample of the cross-section of the weld is intercepted to obtain the following: Figure 3a The results shown; the second option is: use sine wave to modulate the laser power, the modulation frequency is 100HZ, the amplitude is 1.0kW, and the average power is 2.5kW to form a continuous weld bead and intercept the metallographic sample of the weld cross section get as Figure 3b The results shown. from Figure 3a and Figure 3b It can be seen that the method of laser power mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com