Semiconductor device and preparation method thereof, and electronic device

A semiconductor and device technology, applied in the field of semiconductor devices and their preparation methods, and electronic devices, can solve problems such as material layer over-etching, device failure, etc., and achieve the effects of improving device performance, reducing area, and reducing the influence of capillary action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

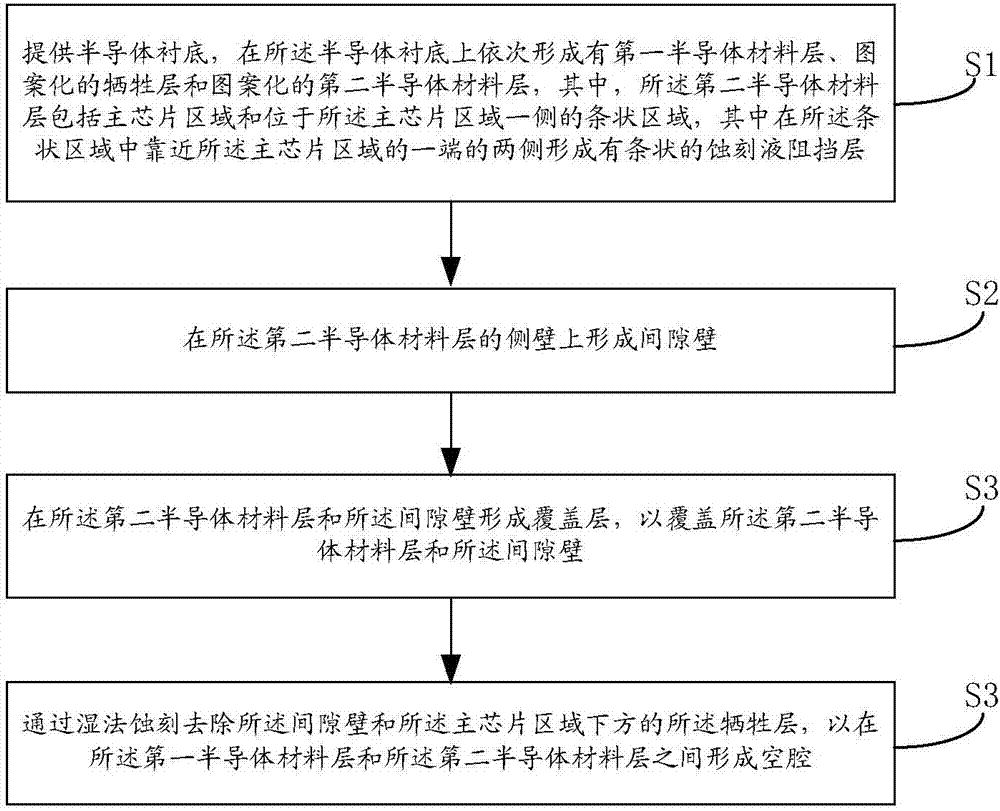

[0049] In order to solve the above problems, the inventor has carried out in-depth analysis and practice on the causes of the problems, and combined his own experience to propose a method for preparing a semiconductor device, the method comprising:

[0050] A semiconductor substrate is provided, on which a first semiconductor material layer, a patterned sacrificial layer and a patterned second semiconductor material layer are sequentially formed, wherein the second semiconductor material layer includes a main chip area and A strip-shaped area located on one side of the main chip area, wherein a strip-shaped etchant barrier layer is formed on both sides of one end of the strip-shaped area close to the main chip area;

[0051] forming spacers on sidewalls of the second semiconductor material layer;

[0052] forming a covering layer on the second semiconductor material layer and the spacer to cover the second semiconductor material layer and the spacer;

[0053] The spacer and t...

Embodiment 1

[0062] Refer below figure 1 with Figure 2a-2e The preparation method of the semiconductor device of the present invention is described in detail, figure 1 Shows a flow chart of the fabrication process of the semiconductor device of the present invention; Figure 2a-2e A schematic cross-sectional view of a structure obtained by sequentially implementing the manufacturing method of the semiconductor device of the present invention is shown.

[0063] The invention provides a method for preparing a semiconductor device, such as figure 1 As shown, the main steps of the preparation method include:

[0064] Step S1: providing a semiconductor substrate on which a first semiconductor material layer, a patterned sacrificial layer and a patterned second semiconductor material layer are sequentially formed, wherein the second semiconductor material layer includes a main A chip area and a strip-shaped area located on one side of the main chip area, wherein a strip-shaped etchant barri...

Embodiment 2

[0119] The present invention also provides a semiconductor device, the semiconductor device comprising:

[0120] semiconductor substrate;

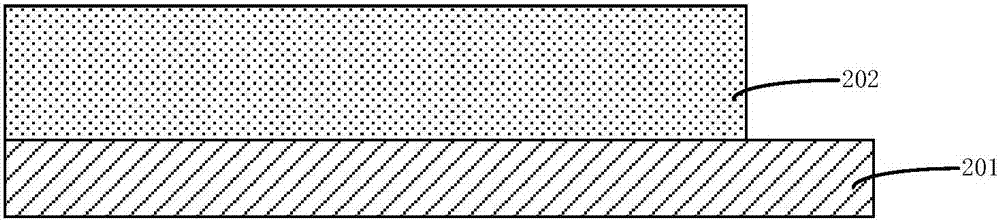

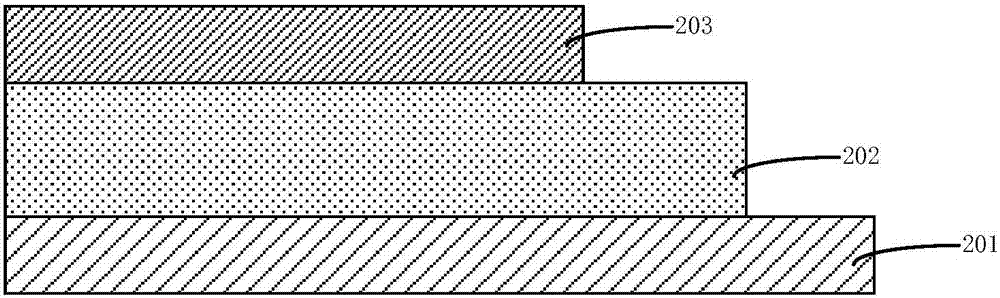

[0121] The first semiconductor material layer 201 is located on the semiconductor substrate;

[0122] The second semiconductor material layer 203 is located above the first semiconductor material layer;

[0123] a cavity located between the first layer of semiconductor material and the second layer of semiconductor material;

[0124] a cover layer 205, located above the second semiconductor material layer and enclosing the cavity;

[0125] Wherein, the second semiconductor material layer includes a main chip area 2031 and a strip-shaped area 2032 located on one side of the main chip area, wherein two sides of one end of the strip-shaped area close to the main chip area are formed with Strip-shaped etchant blocking layer 2034 .

[0126] Wherein the semiconductor substrate (not shown in the figure) may be at least one of the materials ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com