MXene modified composite diaphragm, preparation method thereof, and application in lithium-sulphur battery

A composite diaphragm and lithium-sulfur battery technology, which is applied in the direction of lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of poor cycle stability and low efficiency, and achieve low cost, less time-consuming, improved performance and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Liquid Phase Exfoliation of Monolithic Ti by LiF2 and Dilute Hydrochloric Acid 3 C 2

[0060] (1) Dissolve 2 grams of LiF in 20 ml of 6M hydrochloric acid and stir to dissolve;

[0061] (2) Take 2 grams of Ti 3 AlC 2 Powder, slowly added to the solution in step (1) within 10 minutes, stirred at 45°C for 12 hours to dissolve;

[0062] (3) Centrifuge and wash the solution obtained in step (2) 10 times (3000rpm, 5min each time) to make the pH of the supernatant reach 6.2, then continue to centrifuge for 1 hour (3000rpm), and collect the supernatant. The liquid is stored under argon atmosphere to obtain Ti 3 C 2 Aqueous solution (0.1mg / ml).

[0063] will get Ti 3 C 2 The aqueous solution (0.1mg / ml) was dried under vacuum at room temperature to obtain Ti 3 C 2 Material.

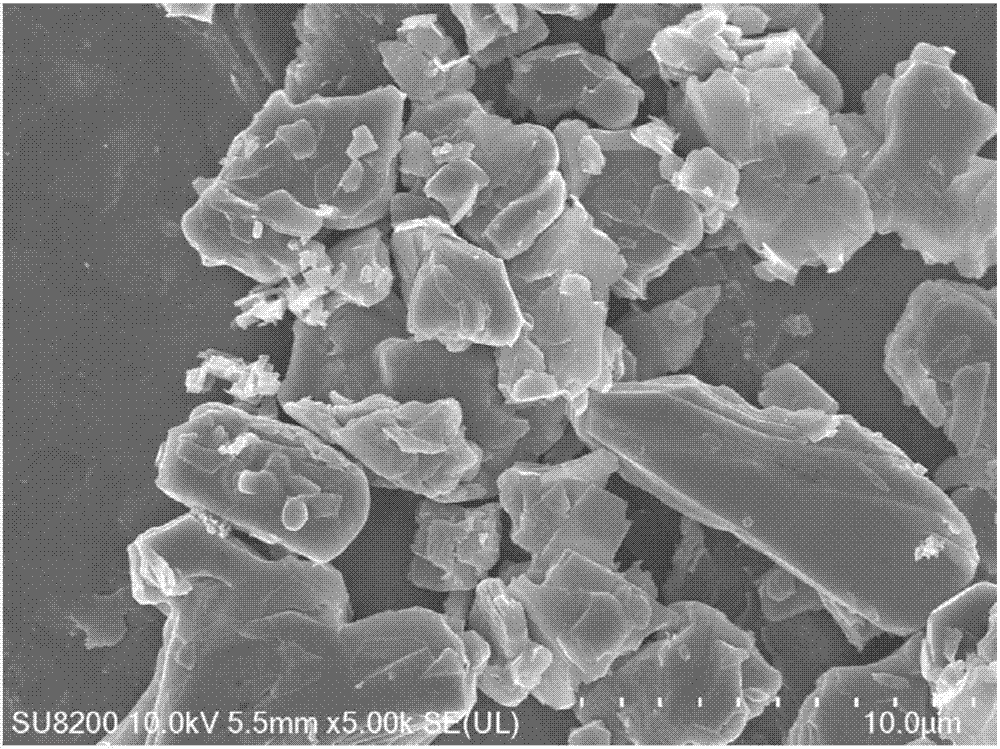

[0064] Ti produced 3 C 2 SEM images of materials, such as figure 2 shown by figure 2 It can be seen that the prepared Ti 3 C 2 The material is a monolithic material.

[0065] Ti produce...

Embodiment 2

[0068] Liquid Phase Exfoliation of Monolithic Ti by LiF2 and Dilute Sulfuric Acid 3 C 2

[0069] (1) Dissolve 5 grams of LiF in 50 ml of 9M sulfuric acid, stir and dissolve in an ice bath;

[0070] (2) Take 5 grams of Ti 3 AlC 2 Powder, slowly added to the solution in step (1) within 10 minutes, stirred at 30°C for 24 hours to dissolve;

[0071] (3) Wash the obtained solution by centrifugation (3000rpm, 5min each time), so that the pH of the supernatant reaches 6.3, and then continue to centrifuge for 0.5 hours (3000rpm), and collect the supernatant, and dry it in vacuum at room temperature to obtain Ti 3 C 2 Material.

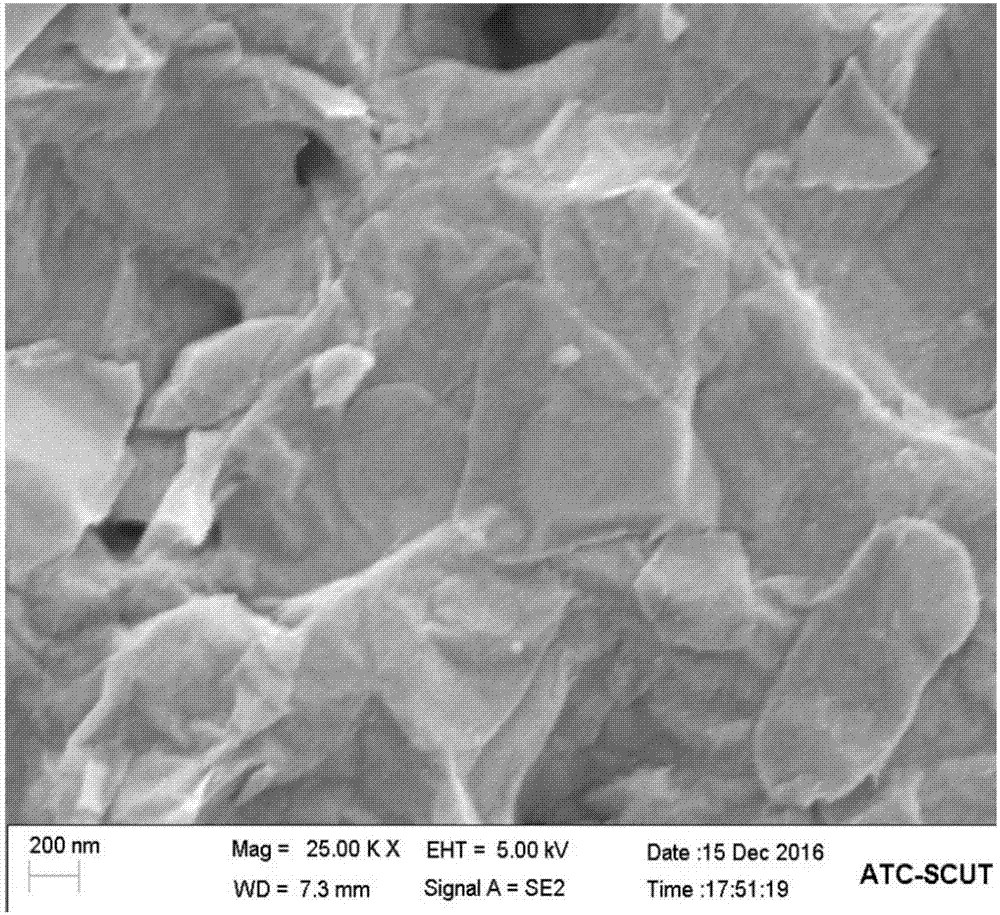

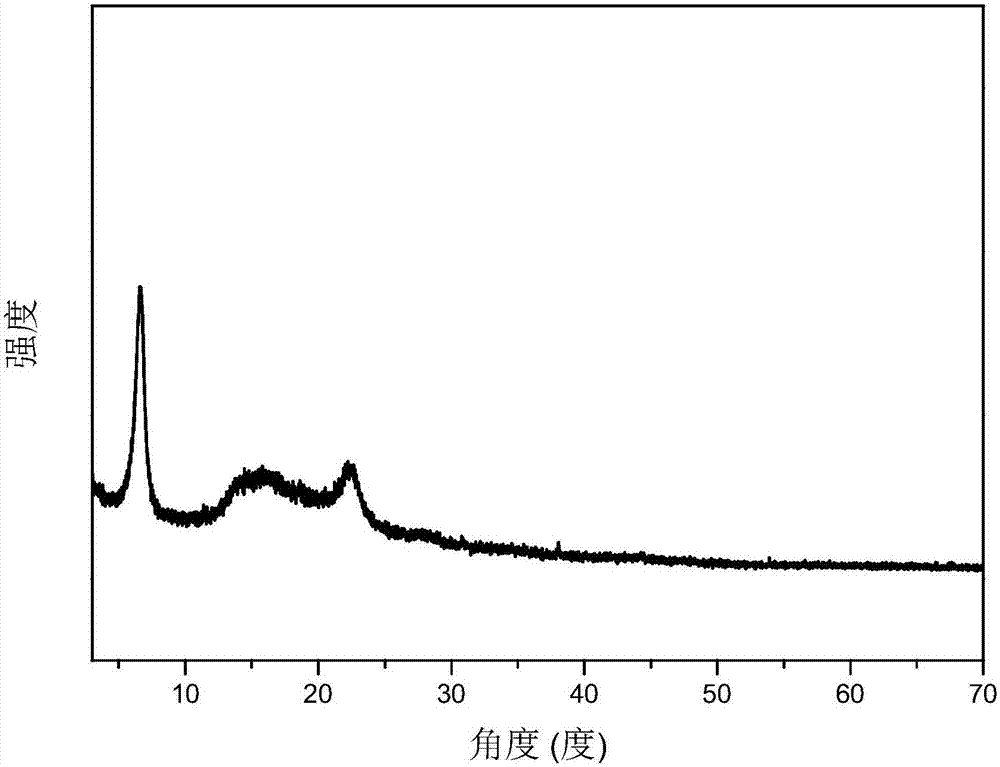

[0072] The Ti obtained in this embodiment 3 C 2 For the SEM image, XRD image and TEM image of the material, please refer to figure 2 , image 3 and Figure 4 , prepared Ti 3 C 2 The material is a single-layer or few-layer material with a nanosheet size of 0.5-1 μm, and the characteristic peak of aluminum in the material has disappeared, indicatin...

Embodiment 3

[0074] Liquid Phase Exfoliation of Monolithic Ti by LiF2 and Concentrated Hydrochloric Acid 3 C 2

[0075] (1) Dissolve 5 grams of LiF in 50 ml of 12M concentrated hydrochloric acid, stir and dissolve in an ice bath;

[0076] (2) Take 5 grams of Ti 3 AlC 2 Powder, slowly added to the solution in step (1) within 10 minutes, stirred at 35°C for 36 hours to dissolve;

[0077] (3) Wash the obtained solution by centrifugation (3000rpm, 5min each time), so that the pH of the supernatant reaches 6.1, and then continue to centrifuge for 0.5 hours (3000rpm), and collect the supernatant, vacuum-dry at room temperature to obtain Ti 3 C 2 Material.

[0078] Ti produced 3 C 2 For the SEM image, XRD image and TEM image of the material, please refer to figure 2 , image 3 and Figure 4 , prepared Ti 3 C 2 The material is a single-layer material with a nanosheet size of 0.5-1 μm, and the characteristic peak of aluminum in the material has disappeared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com