Guadipyr-containing flowable concentrate for seed coating as well as preparation method and application of flowable concentrate for seed coating

A technology of suspension seed coating agent and pentametamiguan, which is applied in the field of suspension seed coating agent containing pentametamiguan, can solve the problems such as short residual effect period, and achieve the effect of low residue, good film-forming property and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

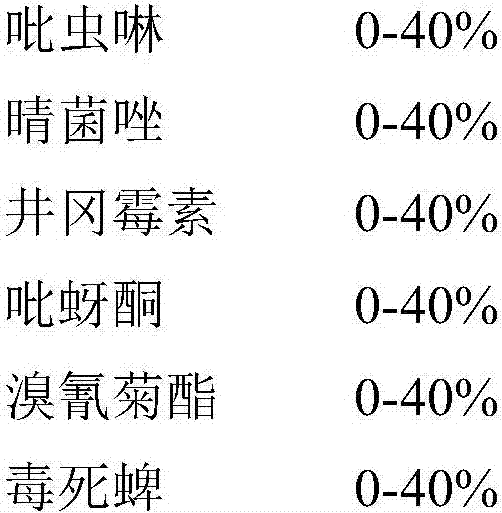

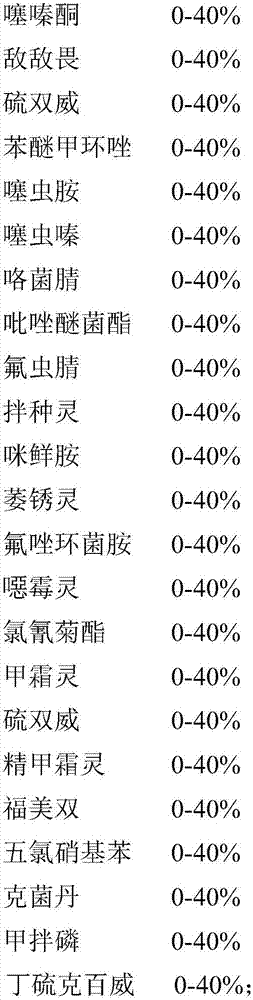

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1: the suspension seed-coating agent of 5% penetamicloguanidine

[0082] Pentamicloguanidine 5%, chitosan 8%, hydroxypropyl methylcellulose MJ 20000PS 0.1%, benzenesulfonate anion YUS-TXC 3%, defoamer DP-304 0.4%, isopropanol 5 %, Everlasting Red F4R 1.2%, water make up 100%.

[0083] Mix the remaining ingredients except hydroxypropyl methylcellulose MJ 20000PS, isopropanol, film-forming agent (chitosan) and defoamer, and grind them in water with a sand mill until the particle size of the material is at After the 1-6μm reaches more than 98%, add hydroxypropyl methylcellulose MJ 20000PS isopropanol solution with a mass concentration of 5%, and film-forming agent and defoamer, mix well, add water to make up 100% and mix well , to obtain the suspension seed coating agent of 5% Pentamicloguanidine.

Embodiment 2

[0084] Embodiment 2: the suspension seed coating of 15% pentacloprid and imidacloprid

[0085] Pentacloprid 5%, imidacloprid 10%, chitosan 10%, hydroxypropyl methylcellulose MJ 40000PS 0.5%, lignosulfonate YUS-WG4 10%, defoamer AF-9909 0.4%, Ethylene glycol 5%, permanent red F4R 1.2%, water make up 100%.

[0086] Mix the remaining ingredients except hydroxypropyl methylcellulose MJ 40000PS, ethylene glycol, film-forming agent (chitosan) and defoamer, and grind them in water with a sand mill until the particle size of the material is at After the 1-6μm reaches more than 98%, add 5% hydroxypropyl methylcellulose MJ 40000PS ethylene glycol solution, film-forming agent and defoamer and mix well, add water to make up 100% and mix well , to obtain a suspension seed coating of 15% pentacloprid and imidacloprid.

Embodiment 3

[0087] Embodiment 3: the suspension seed-coating agent of 20% pentetamicloguanidine and bacendazole

[0088] Pentaclofen 8%, Bacteril 12%, Chitosan 8%, Xanthan Gum 0.2%, Sulfonate Anion YUS-SXC 6%, Defoamer DP-340 0.4%, Propylene Glycol 5%, Permanent Red F4R1.2%, water make up 100%.

[0089] Mix the remaining ingredients except xanthan gum, propylene glycol, film-forming agent (chitosan) and defoamer, and sand them in water with a sand mill until the particle size of the material reaches 98% or more at 1-6 μm , then add a propylene glycol solution of xanthan gum with a mass concentration of 5%, and mix well with a film-forming agent and a defoamer, add water to make up 100% and mix well, to obtain a suspension seed coat of 20% pentaclofen and bacconazole agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com