Molecular bottle brush type reverse phase adsorbent as well as preparation method and application thereof

A technology of particles and initiators, which is applied in the field of separation material preparation, can solve the problems of difficulty in obtaining sensitivity, etc., and achieve the effects of good repeatability, simple synthesis conditions and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 magnetic graphene preparation

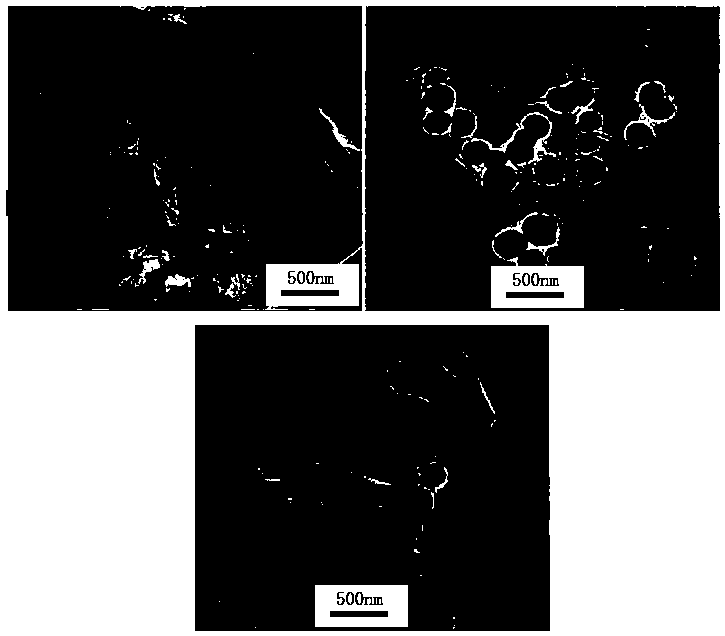

[0032] 0.225 g graphene oxide, 0.6075 g anhydrous FeCl 3 Disperse in 60 mL ethylene glycol, ultrasonically disperse (5~6h), then add 0.225 g sodium citrate, 2.7 g sodium acetate, 1.5 g polyethylene glycol-10000, magnetically stir for 30 min, and transfer to a reaction kettle at 200 °C reaction at room temperature for 12 h, cooled to room temperature, alternately washed with water and ethanol, and vacuum-dried at 50°C to obtain magnetic graphene, see figure 1 , figure 2 b, image 3 a.

Embodiment 2

[0033] Embodiment 2 Preparation of dopamine-coated magnetic graphene

[0034] Disperse 1.0 g of magnetic graphene in 300 mL of Tris-HCl (10 mM pH 8.5) buffer, sonicate for 30 min under mechanical stirring, then add 0.6 g of dopamine, stir mechanically at room temperature for 10 h, wash with water and ethanol, and vacuum at 50 °C Dry, dopamine-coated magnetic graphene, see figure 2 c, image 3 b.

Embodiment 3

[0035] Example 3 Preparation of Molecular Bottlebrush Type Reversed-Phase Adsorption Material Using Dopamine-coated Magnetic Graphene as a Matrix

[0036] Disperse 0.5 g dopamine-coated magnetic graphene in 20 mL redistilled tetrahydrofuran, stir mechanically under ice bath for 30 min, then add 1 mL triethylamine, 1 mL 2-bromoisobutyryl bromide, and ice bath for 3 h, stirred mechanically at 35°C for 12 h, washed three times with tetrahydrofuran, washed with water and methanol, and dried under vacuum at 50°C to obtain primary grafting initiator particles.

[0037] Disperse 0.4 g primary grafting initiator particles, 2.4 mL 2-hydroxyethyl methacrylate (HEMA), 0.1237 g 2,2'-bipyridine (Bpy) in 10 mL redistilled N,N'-dimethyl In formamide (DMF), freeze, vacuum cycle twice, add 0.0568 g cuprous bromide, freeze again, vacuum cycle twice, mechanically stir at 70 °C for 16 h, wash with DMF, methanol, water, wash with EDTANa 2 (0.25 M) / methanol=1 / 1(V / V) Complexation at 40 °C for 4 h, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com