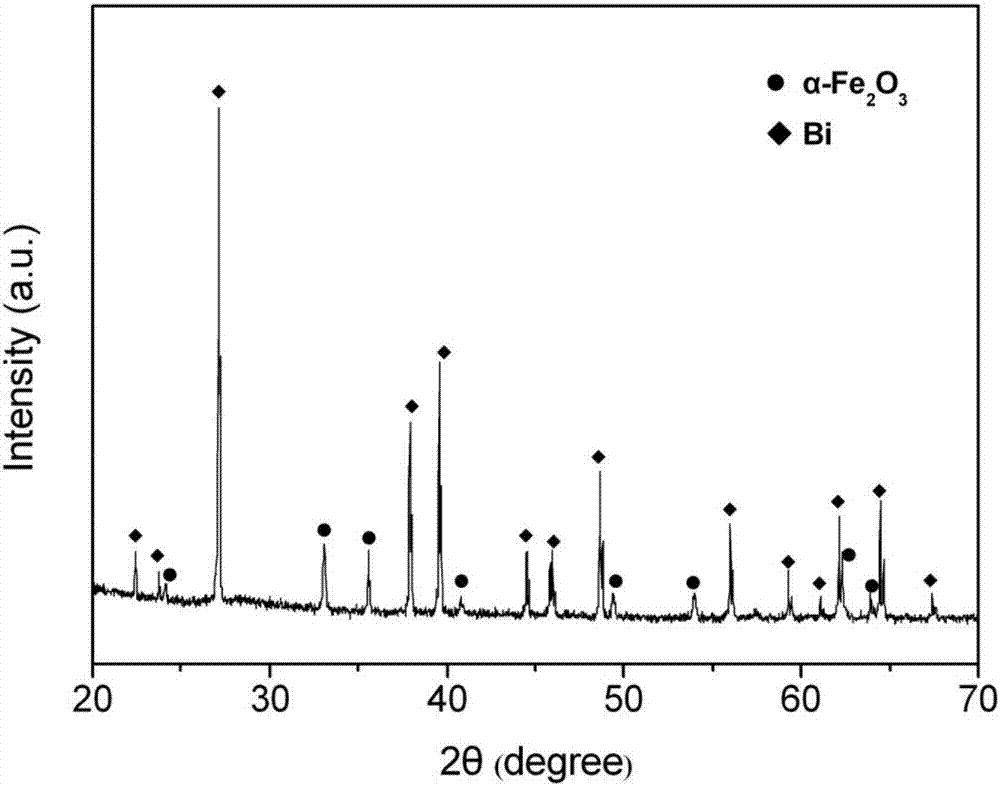

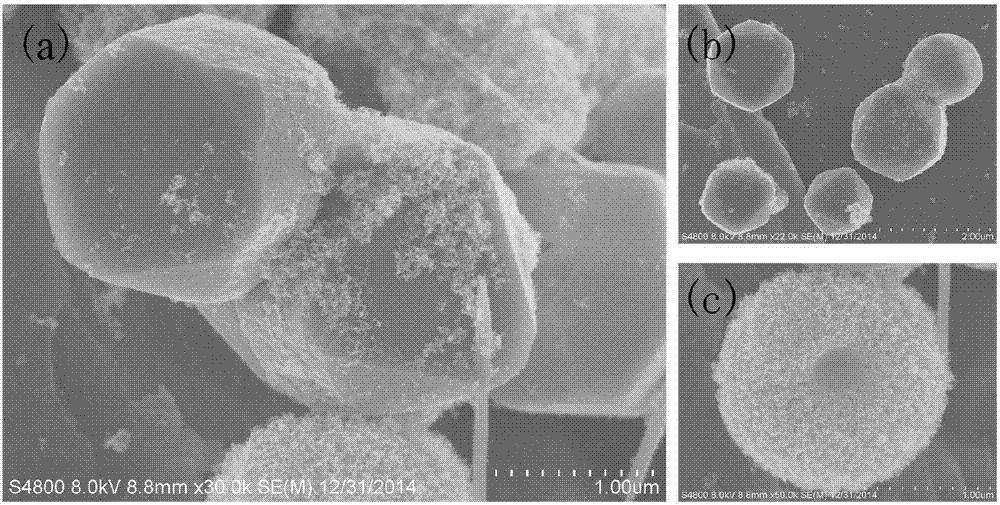

Method for synthesizing alpha-Fe2O3/Bi compound through one-step method

A compound, -fe2o3 technology, applied in the field of one-step synthesis of α-Fe2O3/Bi compound, can solve the problem of high cost of precious metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0011] (1)Fe(NO 3 ) 3 9H 2 O and Bi(NO 3 ) 3 ·5H 2 The molar ratio of O is selected as 1:1, and 1.2093g of Fe(NO 3 ) 3 9H 2 O and 2.4255g of Bi(NO 3 ) 3 ·5H 2 O was added to 20 mL of ethylene glycol and stirred on a magnetic stirrer for 1 h to obtain a clear precursor.

[0012] (2) Weigh 6.5 g of KOH and dissolve it in 8 mL of deionized water by ultrasonication. While stirring, slowly drop the KOH solution into the precursor solution prepared in the previous step.

[0013] (3) Add 0.2 g of sodium dodecylbenzenesulfonate (SDBS) and 0.5 mL of glycerol to the obtained suspension, and continue stirring for 12 hours.

[0014] (4) Add appropriate amount of deionized water to the uniformly stirred suspension to make 37mL, and transfer it into a 45mL hydrothermal reaction kettle. The reaction kettle was placed in a drying oven, and after reacting at a temperature of 170 degrees Celsius for 50 hours, it was naturally cooled to room temperature. Centrifuge the precipitate ...

example 2

[0017] (1)Fe(NO 3 ) 3 9H 2 O and Bi(NO 3 ) 3 ·5H 2 The molar ratio of O is selected as 2:1, and 2.4186g of Fe (NO 3 ) 3 9H 2 O and 2.4255g of Bi(NO 3 ) 3 ·5H 2 O was added to 20 mL of ethylene glycol and stirred on a magnetic stirrer for 1 h to obtain a clear precursor.

[0018] (2) Weigh 6.5 g of KOH and dissolve it in 8 mL of deionized water by ultrasonication. While stirring, slowly drop the KOH solution into the precursor solution prepared in the previous step.

[0019] (3) Add 0.2 g of sodium dodecylbenzenesulfonate (SDBS) and 0.5 mL of glycerol to the obtained suspension, and continue stirring for 12 hours.

[0020] (4) Add appropriate amount of deionized water to the uniformly stirred suspension to make 37mL, and transfer it into a 45mL hydrothermal reaction kettle. The reaction kettle was placed in a drying oven, and after reacting at a temperature of 170 degrees Celsius for 50 hours, it was naturally cooled to room temperature. Centrifuge the precipitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com