Preparation method of strontium carbonate for production of glass substrate

A glass substrate, strontium carbonate technology, applied in the direction of strontium carbonate, calcium carbonate/strontium/barium, etc., can solve the problems of inability to meet high consistency requirements, poor product quality consistency, low resource utilization, etc., to reduce the chance of aggregation and sintering , good consistency, the effect of process environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing strontium carbonate for producing glass substrates, comprising the following steps:

[0028] Step 1: Add 20kg of strontium chloride to 80kg of distilled water, stir to dissolve, then add 0.5kg of ammonia and 1kg of hydrogen peroxide, and stir for 10 minutes; filter, add 0.5kg of dilute sulfuric acid to the filtrate, stir for 10 minutes, filter, and use sodium hydroxide to dissolve the filtrate Adjust the pH to 9, heat the filtrate to 100°C, keep it warm for 10min, and then filter to obtain the impurity-removed strontium chloride solution;

[0029] Step 2, get 20kg ammonium bicarbonate and add in 80kg distilled water, stir and dissolve, obtain ammonium bicarbonate solution;

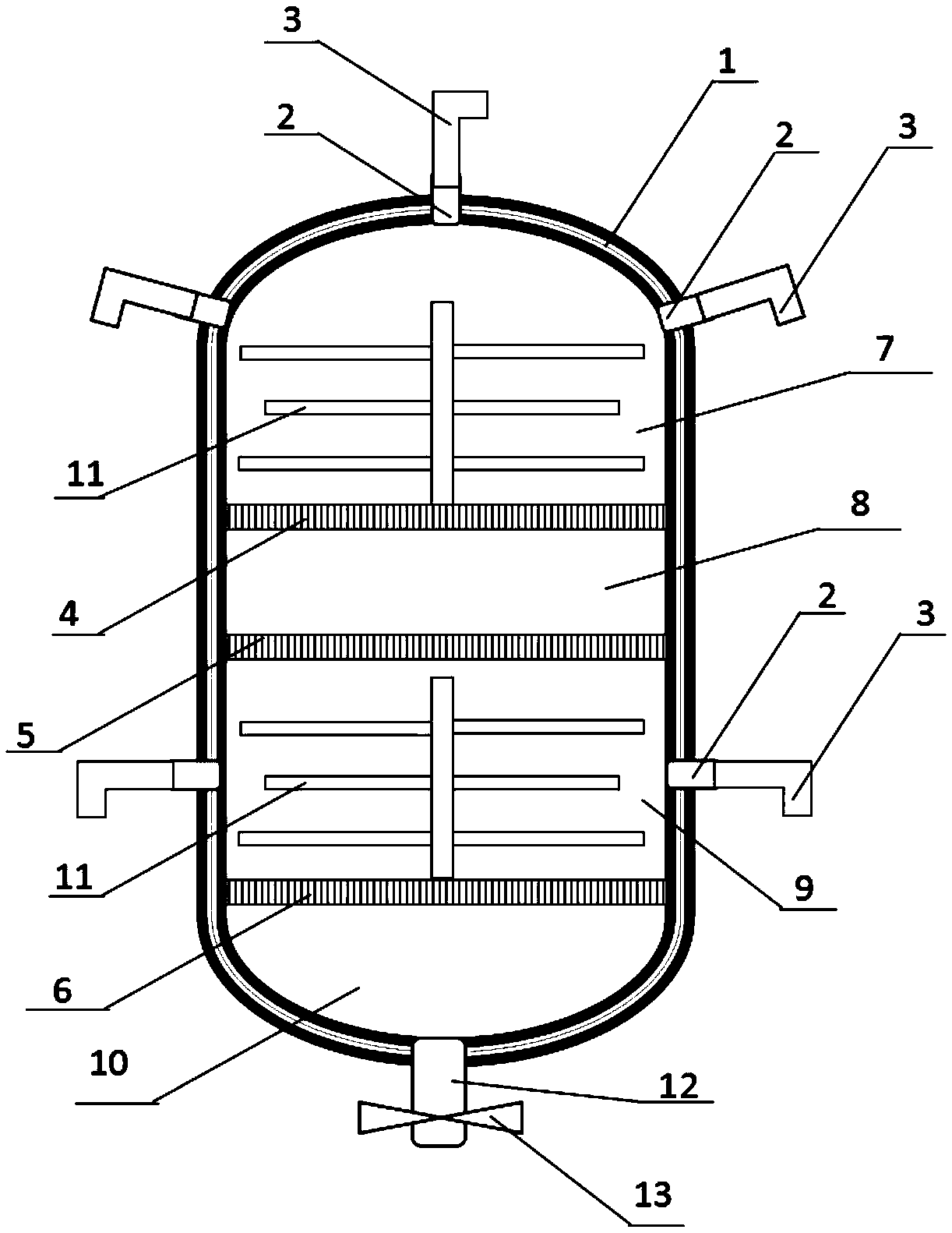

[0030]Step 3. Take strontium chloride solution and ammonium bicarbonate solution with a volume ratio of 1:1 and add them to the crystallization reactor with multi-zone feeding and multi-zone reaction, and then add the crystal form control agent. , stirred and reacted for 1h; ...

Embodiment 2

[0035] A method for preparing strontium carbonate for producing glass substrates, comprising the following steps:

[0036] Step 1: Add 50kg of strontium chloride into 100kg of distilled water, stir to dissolve, then add 1kg of ammonia water and 2kg of hydrogen peroxide, stir for 30 minutes; filter, add 1.5kg of dilute sulfuric acid to the filtrate, stir for 30 minutes, filter, use ammonia water to adjust the pH of the filtrate to 12, heat the filtrate to 100°C, keep it warm for 10min, and then filter to obtain a strontium chloride solution;

[0037] Step 2, get 50kg ammonium bicarbonate and add in 100kg distilled water, stir and dissolve to obtain ammonium bicarbonate solution;

[0038] Step 3. Take strontium chloride solution and ammonium bicarbonate solution with a volume ratio of 1:2 and add them to the crystallization reactor with multi-zone feeding and multi-zone reaction, and then add the crystal form control agent. , stirred and reacted for 3h; obtained reaction materi...

Embodiment 3

[0042] A method for preparing strontium carbonate for producing glass substrates, comprising the following steps:

[0043] Step 1: Take 30kg of strontium chloride and add it to 90kg of distilled water, stir to dissolve, then add 0.6kg of ammonia and 1.5kg of hydrogen peroxide, stir for 20min; filter, add 1kg of dilute sulfuric acid to the filtrate, stir for 30min, filter, and use ammonia to adjust the pH Adjust to 10, heat the filtrate to 100°C, keep it warm for 10 minutes, and then filter to obtain a strontium chloride solution;

[0044] Step 2, get 30kg ammonium bicarbonate and add in 90kg distilled water, stir and dissolve, obtain ammonium bicarbonate solution;

[0045] Step 3: Take strontium chloride solution and ammonium bicarbonate solution with a volume ratio of 1:1 and add them to a crystallization reactor with multi-zone feeding and multi-zone reaction, then add a crystal form control agent, at a temperature of 50°C , stirred and reacted for 2h; obtained reaction mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com