High strength and low shrinkage PP/COC alloy material and preparation method thereof

A technology of alloy material and low shrinkage rate, which is applied in the field of low shrinkage PP/COC alloy material and its preparation, and high strength, which can solve the problem of thermal stability, wear resistance and corrosion resistance of materials, and the limitation of polypropylene application , low strength of polypropylene, etc., to achieve the effect of easy scratch on the surface, wide range of use and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

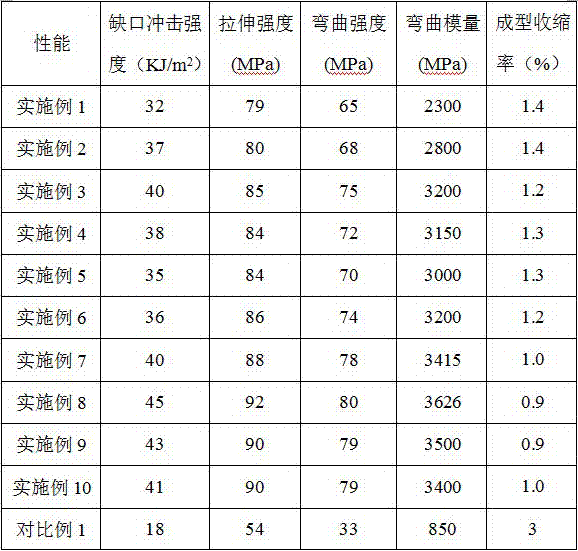

Examples

Embodiment 1

[0037] A high-strength, low-shrinkage PP / COC alloy material and a preparation method thereof, the alloy material comprising the following raw materials in parts by weight:

[0038] 20 parts polypropylene

[0039] Cycloolefin copolymer 50 parts

[0040] Compatibilizer 1 part

[0041] Toughener 1 part

[0042] Dispersant 0.1 parts

[0043] Lubricant 0.2 parts

[0044] Antioxidant 0.1 parts.

[0045] The cyclic olefin copolymer is an amorphous cyclic olefin copolymer with a molecular weight of 4000 and a polymerization degree of 800.

[0046] The compatibilizer is a cyclic acid anhydride type compatibilizer, and the cyclic acid anhydride type compatibilizer is a maleic anhydride grafted polyolefin.

[0047] The toughening agent is methyl methacrylate-butadiene-styrene terpolymer.

[0048] The dispersant is at least one of carmellose sodium and polyoxypropylene.

[0049] Described lubricant is stearic acid amide.

[0050] The antioxidant is β (3,5 di-tert-butyl-4-hydroxyp...

Embodiment 2

[0055] A high-strength, low-shrinkage PP / COC alloy material and a preparation method thereof, the alloy material comprising the following raw materials in parts by weight:

[0056] 35 parts polypropylene

[0057] Cycloolefin copolymer 42 parts

[0058] Compatibilizer 2 parts

[0059] Toughener 2 parts

[0060] Dispersant 0.2 parts

[0061] Lubricant 0.35 parts

[0062] Antioxidant 0.15 parts.

[0063] The cyclic olefin copolymer is an amorphous cyclic olefin copolymer with a molecular weight of 15500 and a polymerization degree of 650.

[0064] The compatibilizer is a carboxylic acid type compatibilizer, and the carboxylic acid type compatibilizer is ethylene-acrylate terpolymer grafted glycidyl ester.

[0065] The toughening agent is at least one of styrene-butadiene thermoplastic elastomer and polyimide.

[0066] The dispersant is at least one of polyoxyethylene copolymer and alkyl polyoxyethylene.

[0067] The lubricant is glycerol trihydroxystearate.

[0068] The ...

Embodiment 3

[0073] A high-strength, low-shrinkage PP / COC alloy material and a preparation method thereof, the alloy material comprising the following raw materials in parts by weight:

[0074] Polypropylene 50 parts

[0075] Cyclic olefin copolymer 35 parts

[0076] Compatibilizer 3 parts

[0077] Toughener 3 parts

[0078] Dispersant 0.3 parts

[0079] Lubricant 0.5 parts

[0080] Antioxidant 0.2 parts.

[0081] The cycloolefin copolymer is an amorphous cycloolefin copolymer with a molecular weight of 26500 and a polymerization degree of 500.

[0082] The compatibilizer is an oxazoline-type compatibilizer, and the oxazoline-type compatibilizer is oxazoline-grafted polystyrene.

[0083] The toughening agent is at least one of acrylonitrile-butadiene-styrene copolymer and chlorinated polyethylene.

[0084] The dispersant is at least one of polyoxypropylene ether and sodium dodecylbenzenesulfonate.

[0085] The lubricant is at least one of N,N'-ethylenebisstearamide and n-butyl stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com