Preparation technology of soybean peptide powder

A technology of soybean peptide powder and preparation process, applied in fermentation and other directions, can solve the problems of high price of peptide products, inability to achieve major breakthroughs in market sales, and high prices of raw and auxiliary materials, so as to improve enzymatic hydrolysis efficiency, product quality, and excellent solubility. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

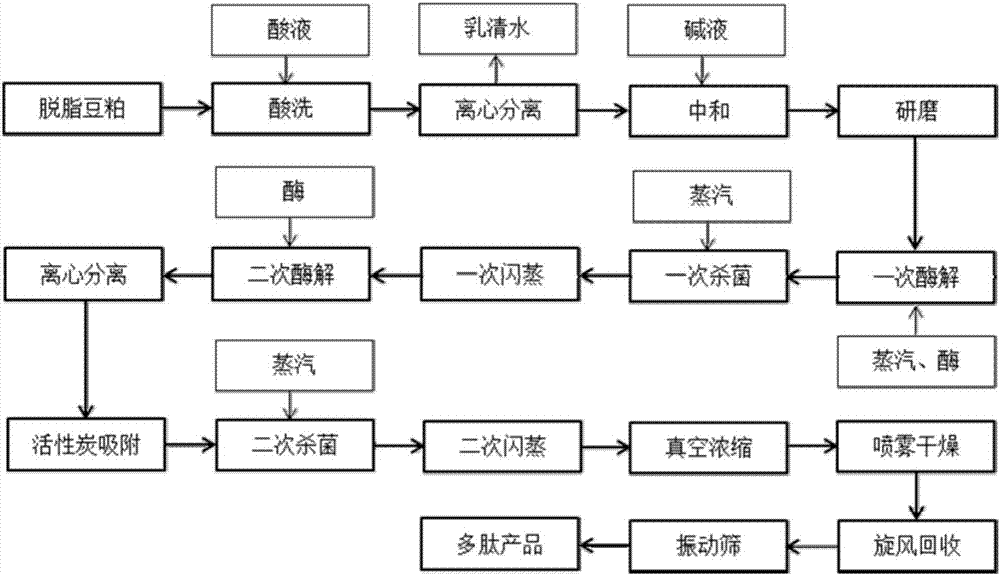

Method used

Image

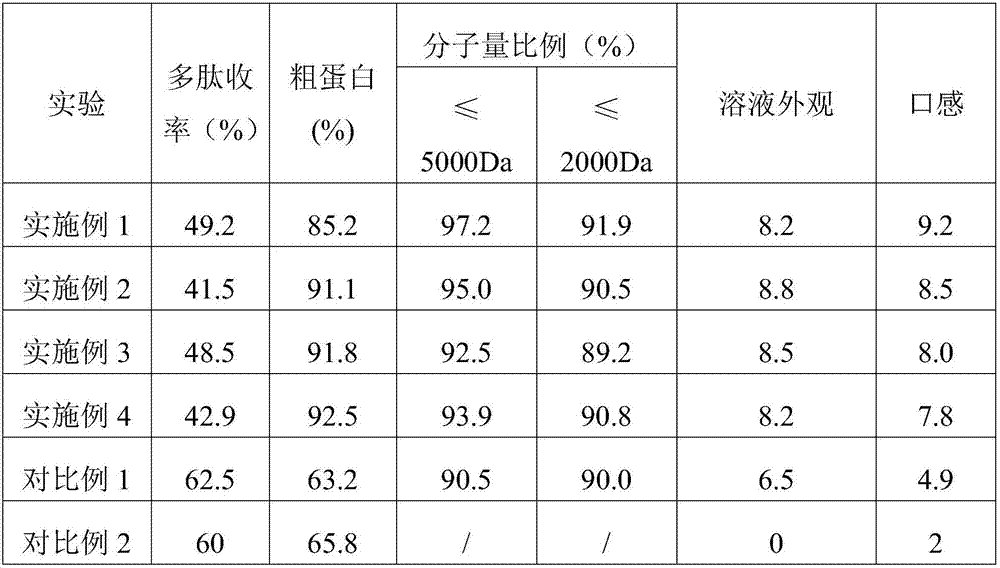

Examples

Embodiment 1

[0065] A preparation process of soybean peptide powder, comprising the steps of:

[0066] (1) Pickling: Mix low-temperature defatted soybean meal (dry basis crude protein 56%, NSI 86%) with water at a ratio of 1:7, water temperature 23°C, adjust pH value to 4.4 with liquid hydrochloric acid, stir and extract at low speed for 40 minutes, stirring speed 60-70r / min;

[0067] (2) Centrifugal separation: centrifuge the feed liquid with a centrifuge, the solid phase moisture is controlled at 80%, the solid phase enters the next process, and the liquid phase is used for other purposes;

[0068] (3) Second pickling: mix the solid phase obtained from the first separation with water at a ratio of 1:2.5, the water temperature is 23°C, adjust the pH value to 4.4 with liquid hydrochloric acid, stir and extract at a low speed for 5 minutes, and the stirring speed is 60-70r / min;

[0069] (4) Secondary centrifugation: the feed liquid is centrifuged with a centrifuge, the solid phase moisture...

Embodiment 2

[0081] A preparation process of soybean peptide powder, comprising the steps of:

[0082] (1) Pickling: Mix low-temperature defatted soybean meal (dry basis crude protein 56%, NSI 86%) with water at a ratio of 1:7, water temperature 23°C, adjust pH value to 4.4 with liquid hydrochloric acid, stir and extract at low speed for 40 minutes, stirring speed 60-70r / min;

[0083] (2) Centrifugal separation: centrifuge the feed liquid with a centrifuge, the solid phase moisture is controlled at 80%, the solid phase enters the next process, and the liquid phase is used for other purposes;

[0084] (3) Second pickling: mix the solid phase obtained from the first separation with water at a ratio of 1:2.5, the water temperature is 23°C, adjust the pH value to 4.4 with liquid hydrochloric acid, stir and extract at a low speed for 5 minutes, and the stirring speed is 60-70r / min;

[0085] (4) Secondary centrifugation: the feed liquid is centrifuged with a centrifuge, the solid phase moisture...

Embodiment 3

[0097] A preparation process of soybean peptide powder, comprising the steps of:

[0098] (1) Pickling: Mix low-temperature defatted soybean meal (dry basis crude protein 58%, NSI 80%) and water at a ratio of 1:20, water temperature 50°C, adjust pH value to 5.0 with liquid hydrochloric acid, stir and extract at low speed for 20 minutes, stir at 60-70r / min;

[0099] (2) Centrifugal separation: centrifuge the feed liquid with a centrifuge, the solid phase moisture is controlled at 70%, the solid phase enters the next process, and the liquid phase is used for other purposes;

[0100] (3) Second pickling: mix the solid phase obtained from the first separation with water at a ratio of 1:2, the water temperature is 50°C, adjust the pH value to 5.0 with liquid hydrochloric acid, stir and extract at a low speed for 15 minutes, and the stirring speed is 60-70r / min;

[0101] (4) Secondary centrifugation: the feed liquid is centrifuged with a centrifuge, the solid phase moisture is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com