A method for improving coalbed methane recovery by self-generated multi-component gas displacement in coal seams

A technology of coalbed methane and recovery rate, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the impact of continuous drainage of coalbed methane wells with stable coal particles, cannot accelerate the desorption rate of adsorbed gas, and disturb the coal seam Continuous drainage system and other issues to achieve the effect of maintaining the original stratum environment, preventing large-scale reproduction, and ensuring coal mining

Inactive Publication Date: 2019-10-01

SOUTHWEST PETROLEUM UNIV

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Another purpose of the present invention is to solve the problem that in the prior art, the microbial plugging removal method cannot accelerate the desorption rate of the adsorbed gas, and the metabolites produced after microbial coalification have no subsequent treatment, and some metabolites may cause secondary blockage of the coal seam At the same time, the gas huff and puff method will disturb the continuous drainage system of the coal seam, which will have a certain impact on the stability of pulverized coal particles and the continuous drainage of coalbed methane wells and other technical problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

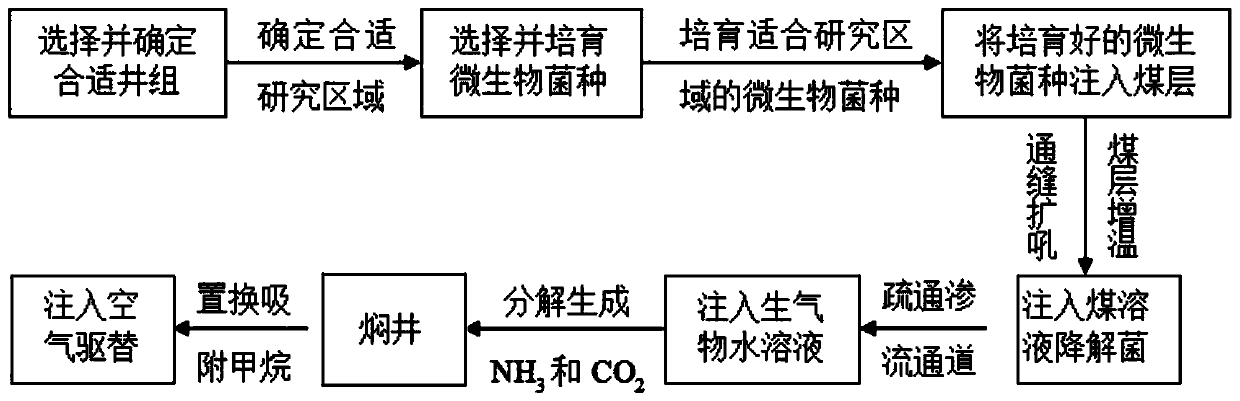

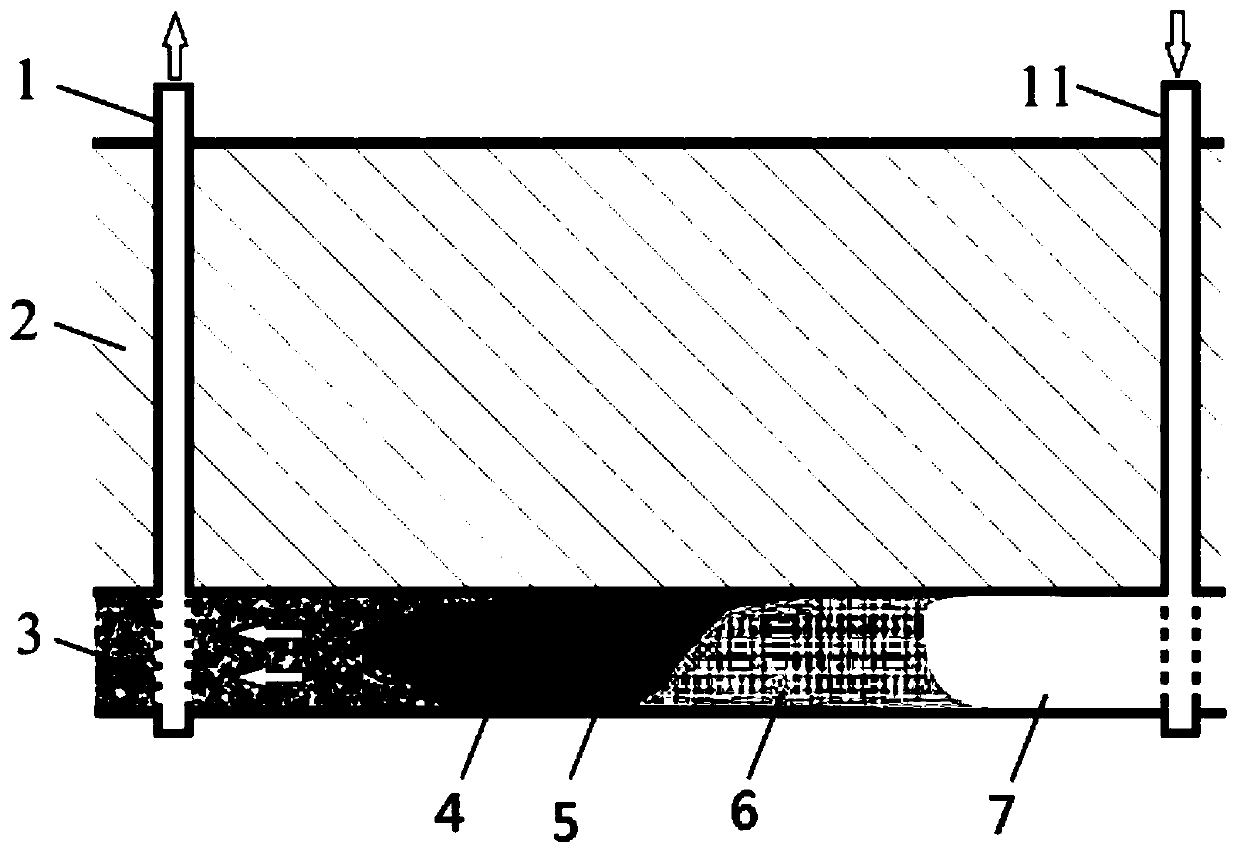

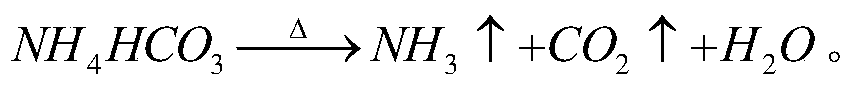

The invention discloses a method for increasing the coalbed methane recovery ratio through coalbed self-generated multicomponent gas displacement. The method comprises the following steps that S1, a target area is selected; S2, coalification microorganism species suitable for the area are selected and cultivated according to the coal component and the coalbed water environment in the target area; S3, the cultivated coalification microorganism species are injected into a coalbed, and coal powder in coalbed fractures and hole channels is dissolved, so that a coal solution is formed; S4, coal solution degrading bacteria are injected into the coalbed so that the coal solution and undissolved substances left in the coalbed fractures can be subjected to decomposition processing; S5, a gas generation substance water solution is poured into the coalbed processed through the step S4; S6, the mouth of a well is sealed, and set-in-well treatment is conducted; and S7, after set-in-well treatment, air is injected into the coalbed for displacement. According to the method, the microbial conversion technology and an ammonium bicarbonate water solution are adopted for production increasing, and the method has the advantages of being simple in process, low in energy consumption, free of pollution and the like which are incomparable to common treatment technologies.

Description

technical field The invention relates to the field of coal bed methane exploitation, in particular to a method for increasing the recovery rate of coal bed methane by alternately injecting gas and liquid into coal seam self-generated multi-component gas for displacement. Background technique Coalbed methane is an efficient and clean energy, a national strategic resource, and an important unconventional oil and gas resource. my country is rich in coalbed methane resources, with huge reserves and wide distribution. As a special oil and gas resource, coalbed methane is distributed in coal seams. At present, coalbed methane has been developed in many coal blocks in China, but the mining effect in most of the research areas is not ideal, mainly due to geological factors such as low pressure, low porosity and low permeability of coal seams. Decision, followed by imperfect mining methods and inadequate mining measures. The cementation degree of the coal seam is low, and the pore...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E21B43/22E21B43/24

Inventor 王超文贾春生彭小龙朱苏阳邓鹏

Owner SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com