Surface passivation liquid and application of surface passivation liquid to CMT crystal surface passivation

A technology of crystal surface and passivation solution, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as complex oxidation process, achieve simple process, reduce surface leakage current, and achieve obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

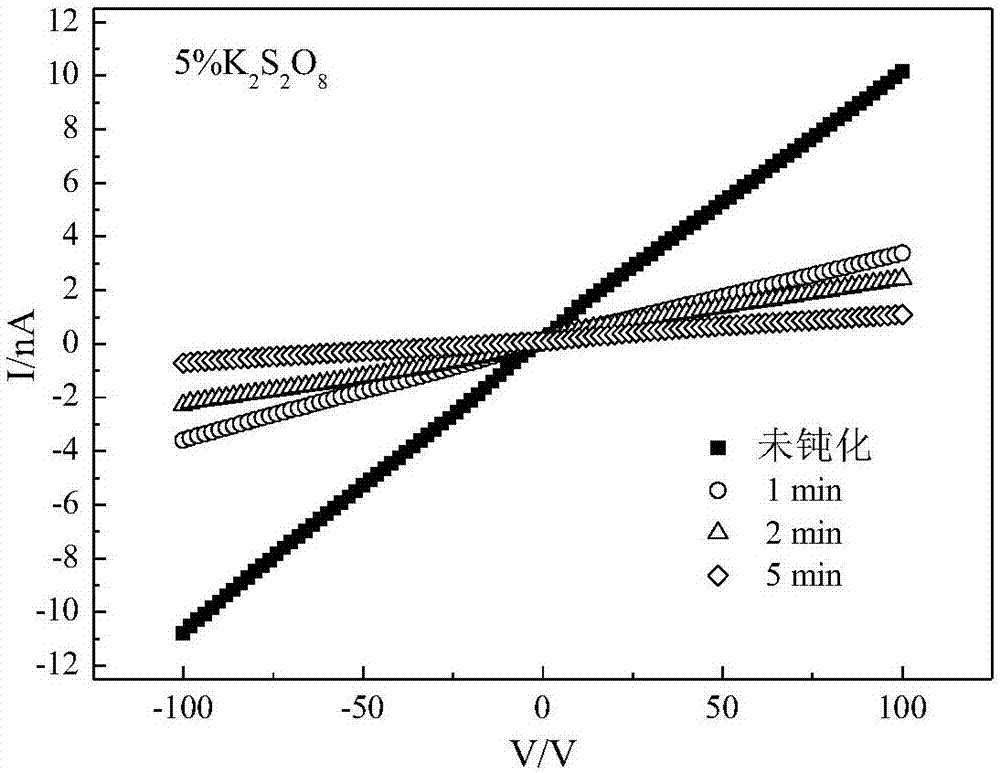

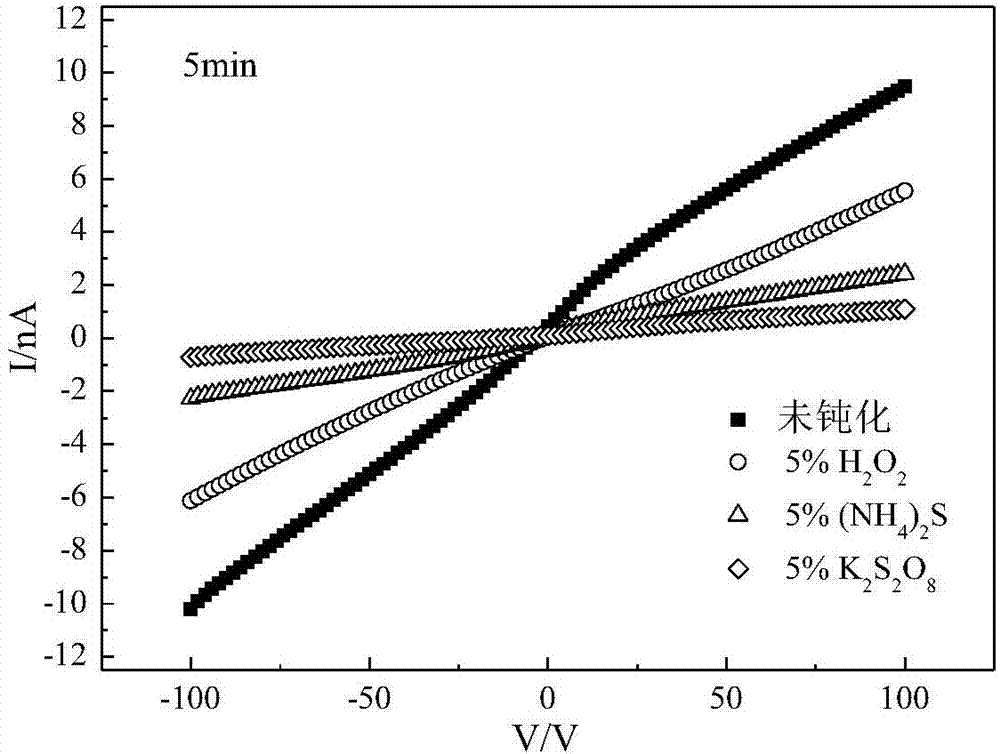

Embodiment 1

[0028] Prepare the beaker of passivation solution clean with deionized water, be the ratio of 5:95 by the mass ratio of potassium persulfate and deionized water, take by weighing 5g potassium persulfate, pour in the beaker that 95g deionized water is housed, Stir magnetically at room temperature to dissolve all the potassium persulfate to obtain a passivation solution with a concentration of 5%. The CMT wafer (size 10×10×2mm) coated with gold electrodes on both sides by chemical method 3 ) into the passivation solution prepared above for surface passivation treatment, the time is 1min, 2min and 5min; the CMT wafer after passivation is taken out, put into deionized water and washed 3 times to remove various residues on the surface ions, and then the wafer was blown dry with nitrogen, and finally a surface-passivated CMT wafer was obtained.

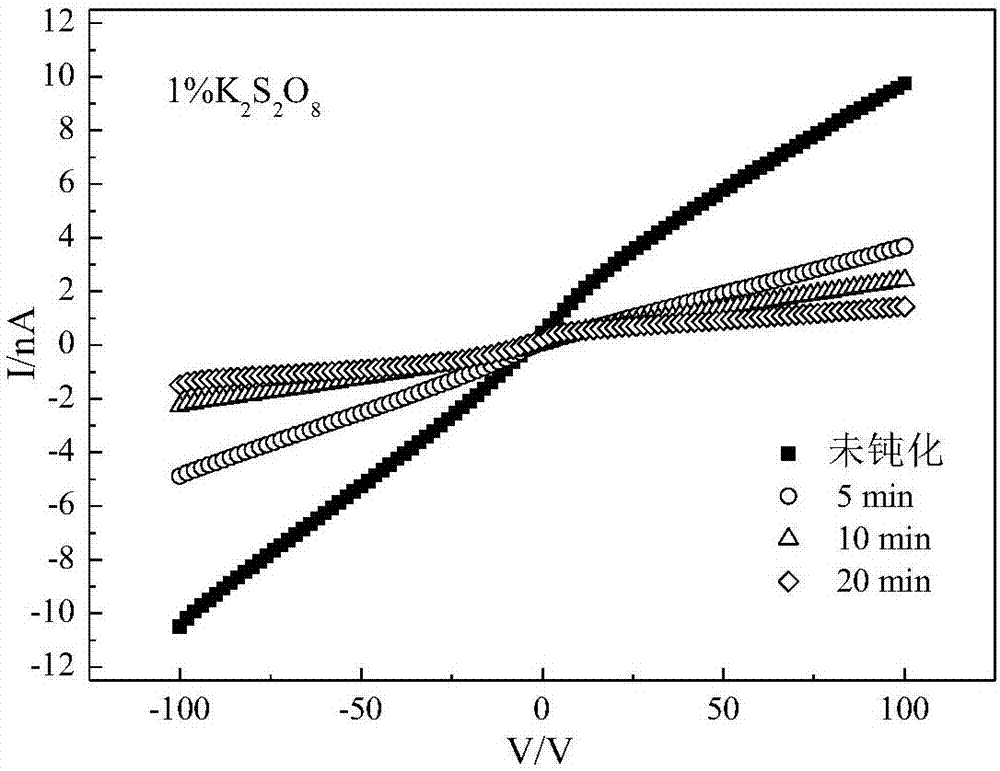

Embodiment 2

[0030] Prepare the beaker of passivation solution and clean it with deionized water, be the ratio of 1:99 by the mass ratio of potassium persulfate and deionized water, take by weighing 1g potassium persulfate, pour in the beaker that 99g deionized water is housed, Stir magnetically at room temperature to dissolve all the potassium persulfate to obtain a passivation solution with a concentration of 1%. The CMT wafer (size 10×10×2mm) coated with gold electrodes on both sides by chemical method 3 ) into the passivation solution prepared above for surface passivation treatment, the time is 5min, 10min and 20min; the CMT wafer after passivation is taken out, put into deionized water and washed 3 times to remove various residues on the surface ions, and then the wafer was blown dry with nitrogen, and finally a surface-passivated CMT wafer was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com