Production method of yogurt containing rich CGFs (chlorella growth factors)

A production method and growth-promoting technology, applied in milk preparations, dairy products, applications, etc., to reduce the incidence of respiratory diseases, protect the respiratory mucosa, and promote detoxification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

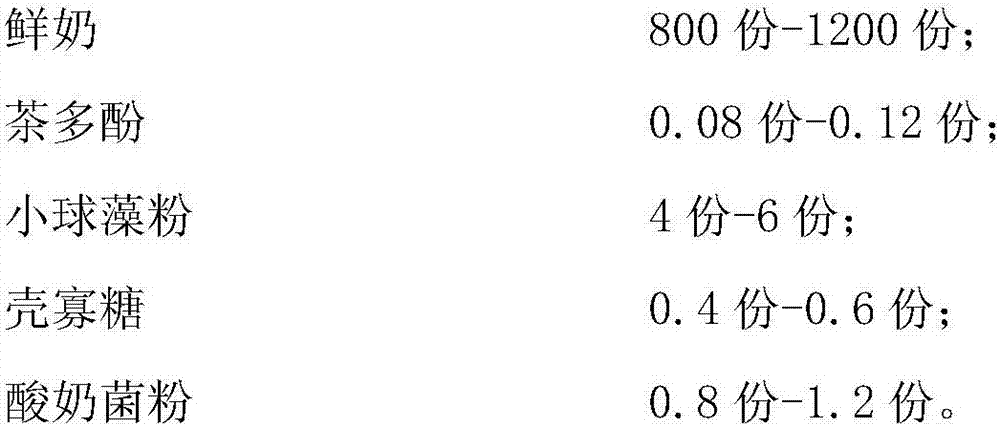

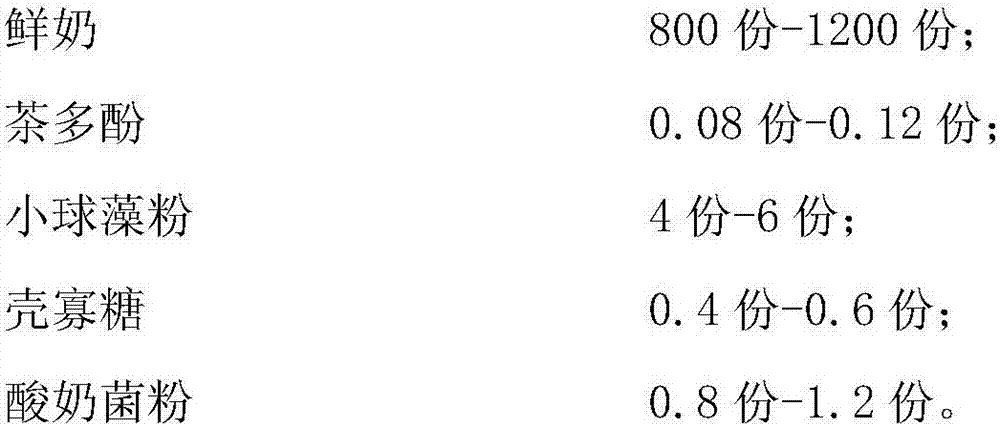

Method used

Image

Examples

Embodiment 1

[0023] Add 1000g of fresh milk, 0.08g of tea polyphenols, 4g of chlorella powder, and 0.4g of chitosan oligosaccharide, after pasteurization, add 0.8g of yogurt bacteria powder and mix well. Fermented under the condition of 35 ℃ for 8 hours.

[0024] After testing, the fermented yoghurt was not fermented enough and the flavor was lacking. According to the same conditions in the fermentation process, the same concentration of chlorella aqueous solution was treated, and the chlorella CGF was extracted in an ultrasonic ice bath, and its effect on the growth of macrophage Ana-1 and RAW264.7 was observed, and it was found that it could significantly promote cell growth and increase value rate reached 17.4%. The content of lactic acid bacteria in yogurt increased by 18%. The shelf life experiment is done in the drug stability test box, and the shelf life is 5 days.

Embodiment 2

[0026] Add 1000g of fresh milk, 0.1g of tea polyphenols, 5g of chlorella powder, and 0.5g of chitosan oligosaccharide, after pasteurization, add 1g of yogurt bacteria powder and mix well. Fermented under the condition of 40 ℃ for 8 hours.

[0027] After testing, the fermented yogurt has a good degree of fermentation and a good flavor. According to the same conditions in the fermentation process, the same concentration of chlorella aqueous solution was treated, CGF was extracted in an ultrasonic ice bath, and its effect on the growth of macrophage Ana-1 and RAW264.7 was observed. It was found that it could also significantly promote cell growth, and the value-added rate reached 20.1%. The content of lactic acid bacteria in the counting unit yogurt is increased by 20%. The shelf life experiment is done in the drug stability test box, and the shelf life is 8 days.

Embodiment 3

[0029] Add 1000g of fresh milk, 0.12g of tea polyphenols, 6g of chlorella powder, and 0.6g of chitosan oligosaccharide, after pasteurization, add 1.2g of yogurt bacteria powder and mix well. Fermented under the condition of 45 ℃ for 8 hours.

[0030] After testing, the fermented yoghurt has a relatively good degree of fermentation, a slight sour taste, and a good flavor. According to the same conditions of the fermentation process, the same concentration of chlorella aqueous solution was treated, and CGF was extracted in an ultrasonic ice bath, and its effect on the growth of macrophage Ana-1 and RAW264.7 was observed. It was found that the ability to promote cell growth was weak, and the value-added rate was 9.3 %. The content of lactic acid bacteria in the counting unit yogurt is increased by 12%. The shelf life experiment is done in the drug stability test box, and the shelf life is 6 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com