Method for measuring content of silicon dioxide in gold ore

A technology of silica and gold mines, applied in the field of analytical chemistry, can solve the problems of no test analysis method, a blank, etc., and achieve the effects of short measurement period, good precision and accuracy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

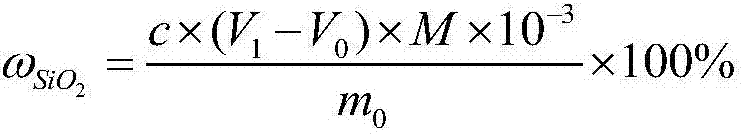

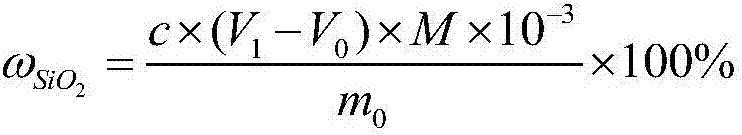

Method used

Image

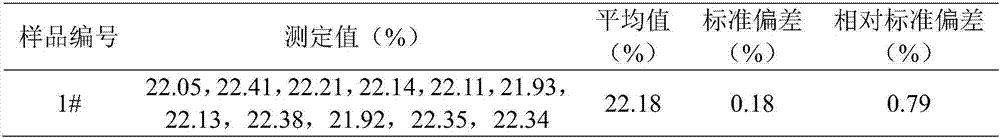

Examples

Embodiment 1

[0030] Step 1. After pulverizing and drying the gold ore, accurately weigh 0.2000g sample and put it into a nickel crucible, then add 3g potassium hydroxide and 0.3g potassium nitrate;

[0031] Step 2: Heating the nickel crucible to 300°C in a muffle furnace at a low temperature, keeping the temperature constant for 20 minutes, and then heating up to 550°C for 15 minutes to melt;

[0032] Step 3. Take out the nickel crucible from the muffle furnace, place it for 10 minutes, put the whole nickel crucible into a 400ml plastic cup, add 10mL of boiling water to the nickel crucible, cover the plastic cup with a watch glass, and wait for the nickel crucible to leaching After the reaction is complete, flush all the contents in the nickel crucible with water into a plastic cup, and take out the nickel crucible;

[0033] Step 4: Add 15 mL of nitric acid with a concentration of 1.42 g / mL into the plastic cup, mix well and cool to room temperature;

[0034] Step 5. Add 5mL of potassium ...

Embodiment 2

[0058] A kind of method specific steps of measuring silicon dioxide content in gold ore are as follows:

[0059] Step 1, after pulverizing and drying the gold ore, accurately weigh 0.3000g sample and put it into a nickel crucible, then add 5g potassium hydroxide and 0.5g potassium nitrate;

[0060] Step 2: Heat the nickel crucible to 300°C in a muffle furnace at low temperature, keep the temperature constant for 30 minutes, and then heat up to 650°C for 30 minutes to melt;

[0061] Step 3. Take out the nickel crucible from the muffle furnace, place it for 10 minutes, put the whole nickel crucible into a 400ml plastic cup, add 15mL boiling water to the nickel crucible, cover the plastic cup with a watch glass, and wait for the nickel crucible to leaching After the reaction is complete, flush all the contents in the nickel crucible with water into a plastic cup, and take out the nickel crucible;

[0062]Step 4: Add 20 mL of nitric acid with a concentration of 1.42 g / mL into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com