Mn-based cathode material of Na-ion battery

A technology of sodium ion battery and cathode material, applied in the field of electrochemistry, can solve the problems of changing material structure, restricting the widespread promotion of sodium ion battery, reducing the practicability of manganese-based layered materials, etc. The effect of good environmental stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) According to the molar ratio of 0.5:0.4:0.1:0.1, accurately weigh the corresponding mass of Na 2 CO 3 , Mn 2 o 3 , NiO and TiO 2 , put into the ball mill tank, and then add ball mill balls into it, and ball mill for 20h under the condition of 200r / min, and mix the above precursors evenly.

[0036] (2) Press the ball-milled mixture into a disc with a diameter of 16 mm under a pressure of 4 MPa.

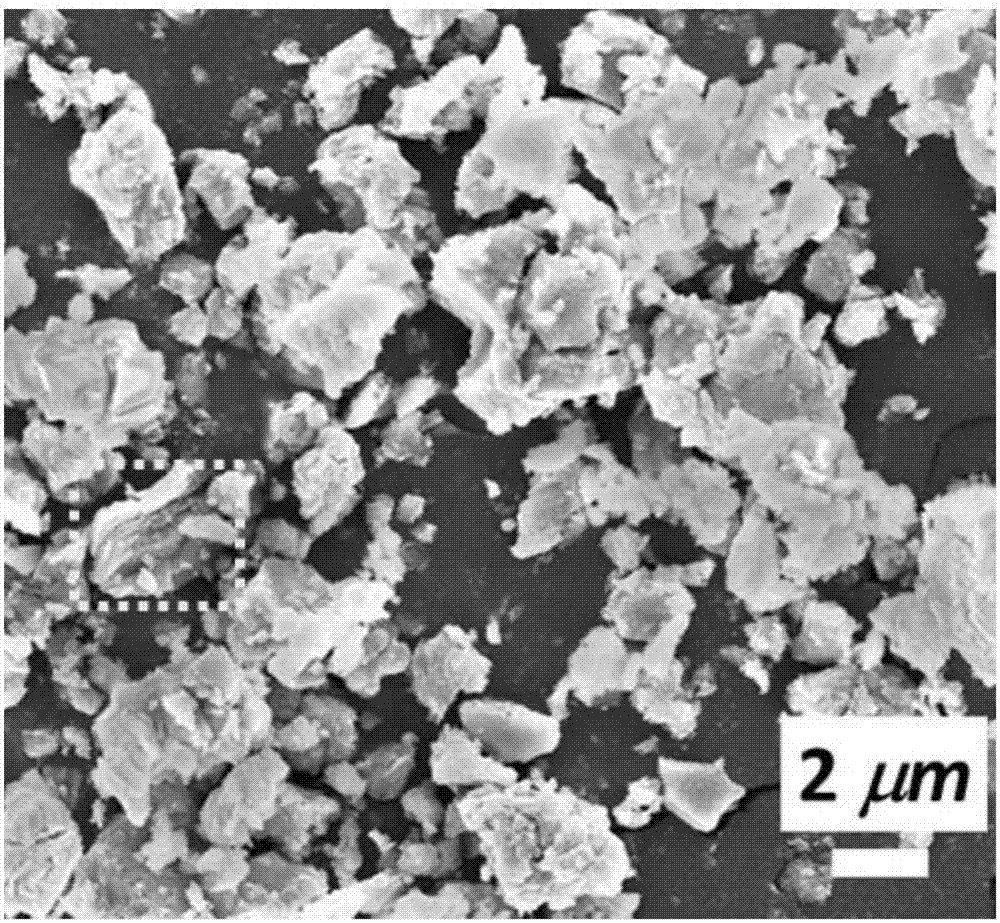

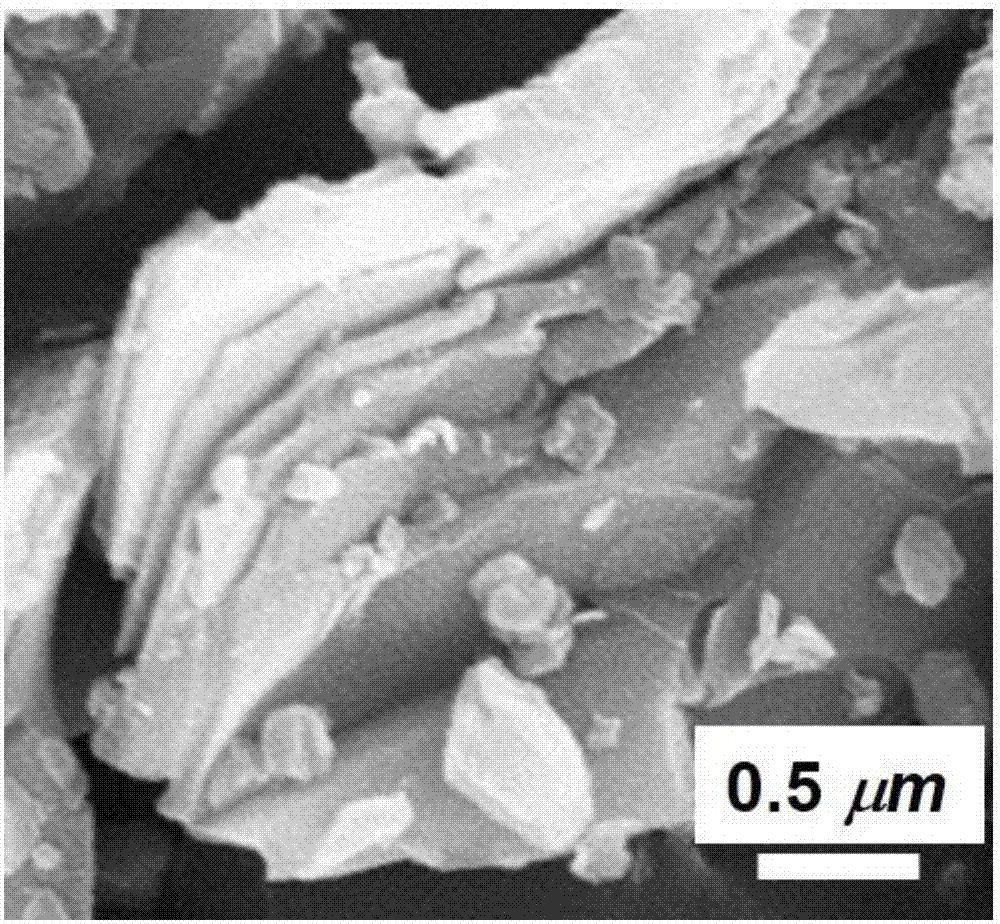

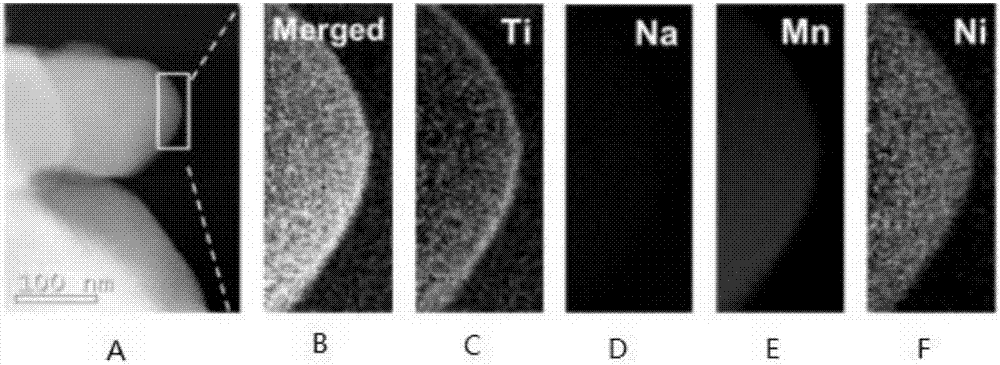

[0037] (3) Place the sheet-shaped sample obtained in step (2) in a tube furnace, raise the temperature to 900°C at 5°C / min in an oxygen atmosphere, and heat-treat for 15 hours; quench to room temperature to obtain a manganese-based positive electrode material for a sodium-ion battery , whose molecular formula is NaMn 0.8 Ni 0.1 Ti 0.1 o 2 , the material is in the form of powder particles with a particle size of 2-10 μm.

[0038] The manganese-based positive electrode material of the sodium-ion battery prepared above was characterized, and the results were as follows...

Embodiment 2

[0042] Change the molar ratio of each substance, according to the molar ratio of 0.5:0.45:0.05:0.05, accurately weigh the corresponding mass of Na 2 CO 3 , Mn 2 o 3 , NiO and TiO 2 , according to the method of step (1)-(3) in embodiment 1, the manganese-based cathode material of sodium-ion battery is prepared, and its molecular formula is NaMn 0.9 Ni 0.05 Ti 0.05 o 2 .

Embodiment 3

[0044] Change the molar ratio of each substance, according to the molar ratio of 0.5:0.35:0.15:0.15, accurately weigh the corresponding mass of Na 2 CO 3 , Mn 2 o 3 , NiO and TiO 2 , according to the method of step (1)-(3) in embodiment 1, the manganese-based cathode material of sodium-ion battery is prepared, and its molecular formula is NaMn 0.7 Ni 0.15 Ti 0.15 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com