Cottonseed protein extraction equipment

An extraction equipment and cottonseed protein technology, which is applied in the field of cottonseed processing, can solve the problems of increasing the amount and difficulty of waste methanol recovery and purification, free gossypol and aflatoxin are difficult to control, and cottonseed has moldy aflatoxin content, etc., to achieve The effect of reducing the amount of cottonseed protein, reducing the consumption of methanol solvent, and reducing the amount of steam used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

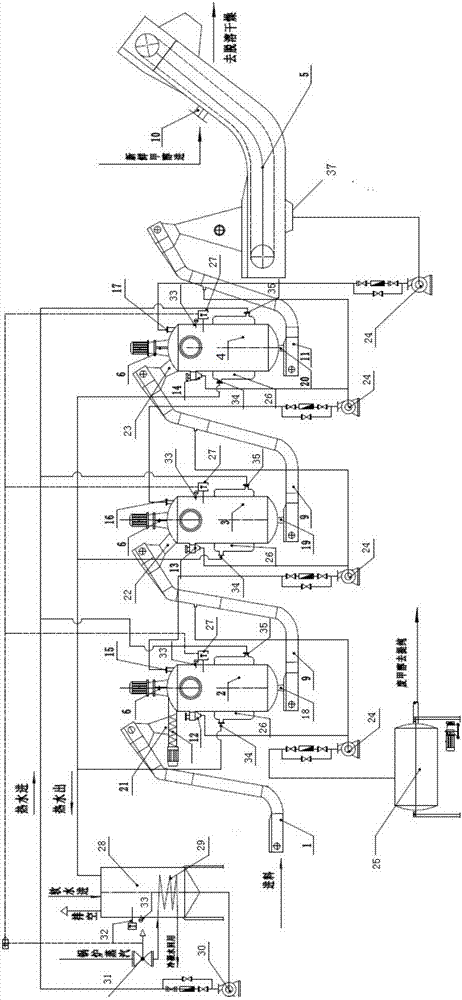

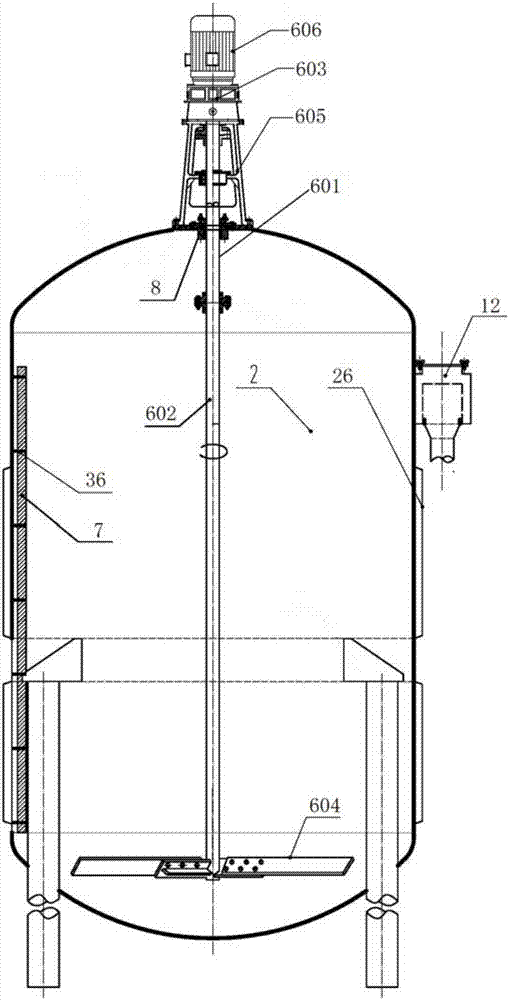

[0062] The cottonseed is pre-treated to obtain cotton kernels, and then the cotton kernels are degreased to obtain degreased cotton meal; the degreased cotton meal is sent from the feeding device 1 to the primary leaching tank 2, and extracted at 30°C for the first stage Leaching and extraction, the material is discharged from the bottom of the tank after continuous stirring in the tank, and is sent to the secondary leaching tank 3 by the first conveyor 9, extracted at 40°C for secondary leaching and extraction, and then discharged by the first conveyor 9 after continuous stirring. into the tertiary leaching tank 4, extracted at 45°C for tertiary leaching and extraction, and then the material discharged from the tertiary leaching tank 4 is sent to the leaching and draining machine 5 to drain by the second conveyor 11, and the material is drained and then transported to Desolvation and drying. The extraction time of the material is 10 minutes under continuous stirring in the le...

Embodiment 2

[0065] The cottonseed is pre-treated to obtain cotton kernels, and then the cotton kernels are degreased to obtain degreased cotton meal; the degreased cotton meal is sent from the feeding device 1 to the primary leaching tank 2, and extracted at 40°C for primary extraction Leaching and extraction, the material is discharged from the bottom of the tank after continuous stirring in the tank, and is sent to the secondary leaching tank 3 by the first conveyor 9, extracted at 35°C for secondary leaching and extraction, and then discharged by the first conveyor 9 after continuous stirring. into the tertiary leaching tank 4, extracted at 50°C for tertiary leaching and extraction, and then the material discharged from the tertiary leaching tank 4 is sent to the leaching and draining machine 5 by the second conveyor 11 to drain, and the material is drained and then transported to Desolvation and drying. The extraction time of the material is 15 minutes under continuous stirring in the...

Embodiment 3

[0069] The cottonseed is pre-treated to obtain cotton kernels, and then the cotton kernels are degreased to obtain degreased cotton meal; the degreased cotton meal is sent from the feeding device 1 to the primary leaching tank 2, and extracted at 40°C for primary extraction Leaching and extraction, the material is discharged from the bottom of the tank after continuous stirring in the tank, and sent to the secondary leaching tank 3 by the first conveyor 9, extracted at 45°C for secondary leaching and extraction, after continuous stirring, it is discharged from the first conveyor 9 into the tertiary leaching tank 4, extracted at 55°C for tertiary leaching and extraction, and then the material discharged from the tertiary leaching tank 4 is sent to the leaching and draining machine 5 to drain by the second conveyor 11, and the material is drained and then transported to Desolvation and drying. The extraction time of the material is 25 minutes under continuous stirring in the lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com