Process for extracting and purifying total flavonoids of Physalis pubescens fruits under ultrasonic assistance

A technology of auxiliary extraction and ultrasonic wave, applied in the direction of cosmetics, cosmetic preparations, plant raw materials, etc., can solve the problems of affecting scientific research and application, large solvent consumption, low efficiency, etc., to maintain antioxidant activity, reduce extraction solvent, consume less Can less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Single-factor optimization of flavonoids extraction from berry berry

[0022] 1.1 Optimization of solid-liquid ratio

[0023] When the solid-liquid ratio was 1:10, 1:30, 1:50, 1:70, and 1:90 (g / mL), the effect of the solid-liquid ratio on the flavonoid yield and antioxidant activity was investigated, and the experiment was repeated 3 times. . The results showed that the flavonoid yield and antioxidant activity were the best when the solid-liquid ratio was in the range of 1:30-1:70.

[0024] 1.2 Optimization of solvent concentration

[0025] Investigate the effect of solid-liquid ratio on flavonoid yield and antioxidant activity when ethanol concentration is 20%, 40%, 60%, 80%, and 95%, and the experiment is repeated 3 times. The results show that the flavonoid yield and antioxidant activity are the best in the range of ethanol concentration of 60-95%.

[0026] 1.3 Optimization of extraction time

[0027] Investigate the effect of extraction time of 10, 20, 30, 40, ...

Embodiment 2

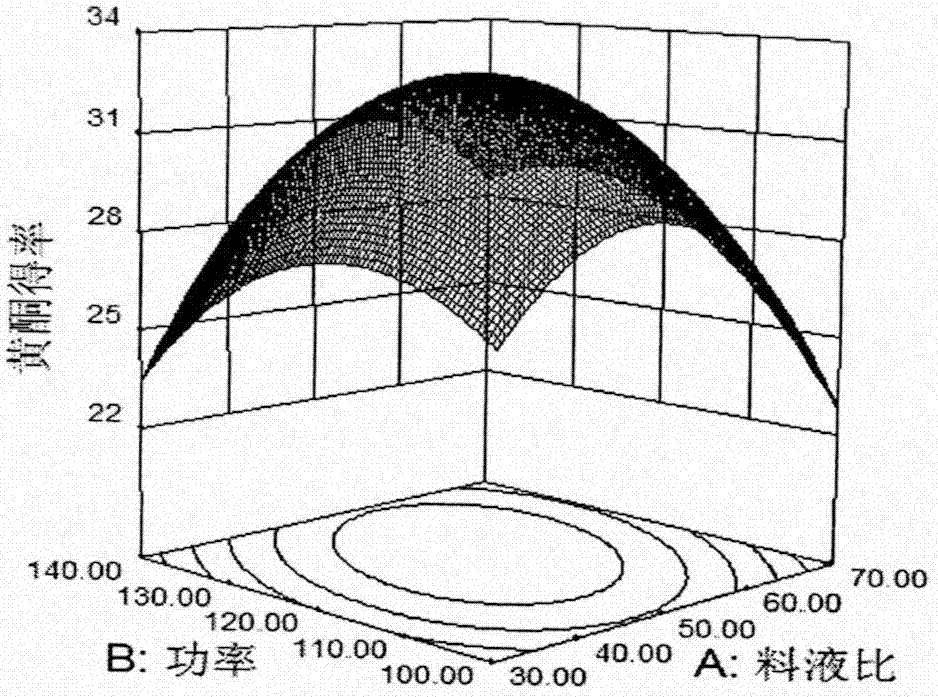

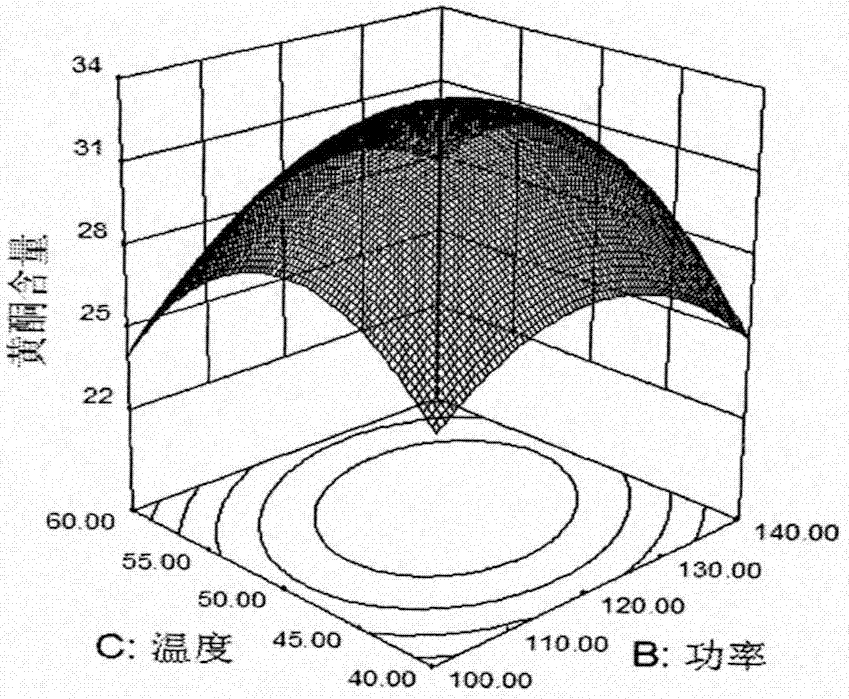

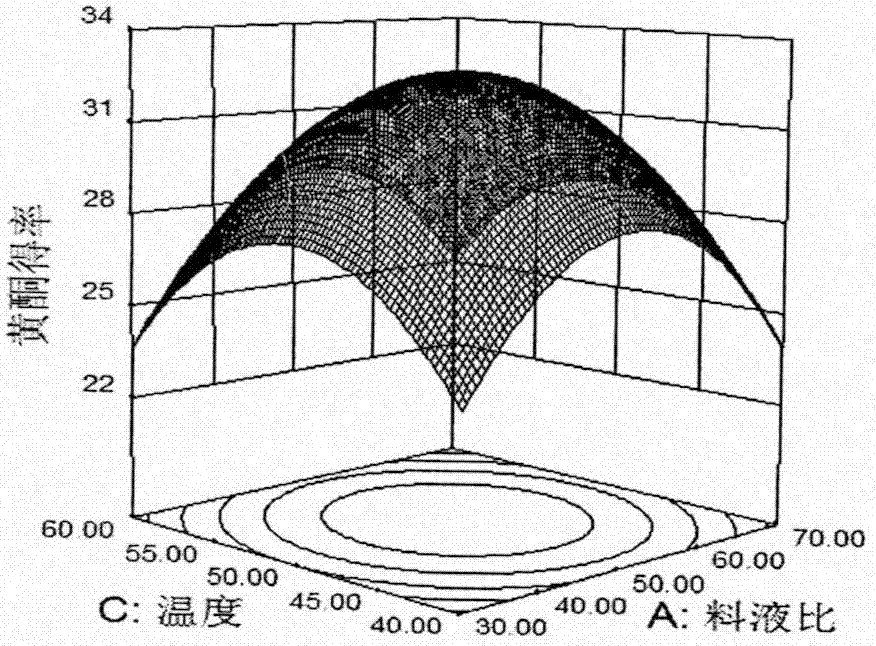

[0033] Multi-factor optimization of process parameters for extraction of flavonoids from berry berry

[0034] According to the above single-factor experimental results, the three factors of solid-liquid ratio, power and temperature were further optimized, and regression analysis was performed on the data, a response regression model was established, and a quadratic regression equation was obtained by fitting.

[0035] Table 1 Test factor level table

[0036]

[0037] According to the single factor test results, combined with the experimental conditions to select the solid-liquid ratio X 1 , Power X 2 , temperature X 3 It is the three elements of the optimization experiment of flavonoid extraction from Physalis edulis fruit, the fixed ethanol concentration is 80%, and the extraction time is 30min. Experiments were carried out at the levels of factors designed in Table 2, and the experimental results are shown in the table below.

[0038] Table 2 Experimental design schem...

Embodiment 3

[0048] Purification process of total flavonoids in berry fruit by macroporous resin method

[0049] 3.1 The relationship between macroporous resin and flavonoids of Physalis edulis fruit static adsorption and desorption

[0050] Static adsorption and desorption tests were carried out on AB-8 and D101. The results are shown in Table 4. The adsorption rate and desorption rate of AB-8 are higher than those of D101.

[0051] Table 4 Resin adsorption and desorption tests

[0052]

[0053] 3.2 Optimization of sample concentration

[0054] Add resin AB-8 into about 20mL of the chromatographic column (2.0cm×30cm), and prepare 5 parts of sample solutions with different mass concentrations of the crude flavonoid powder of Physalis edulis fruit, the concentrations are 1.0mg / mL, 2.0mg / mL, 3.0mg / mL, 4.0mg / mL and 5.0mg / mL, the sample loading speed is 2mL / min, and the other factors are kept constant. The relationship between the concentration of the sample solution and the adsorption r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com